Emulsified work liquid for efficient molded line cutting and preparation method

A working liquid and wire cutting technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of dry skin, redness, etc., and achieve the effects of easy cleaning, environmental protection, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare the following components in parts by weight:

[0026] 20 parts of polyethylene glycol, 20 parts of monoethanolamine, 10 parts of pH regulator, 5 parts of sodium citrate, 15 parts of s-triazine, and 25 parts of triisopropanolamine.

[0027] Under the condition of constant stirring, add water-soluble lubricant, buffer emulsifier, rust inhibitor, bactericide, and grinding aid to the deionized water successively, and stir for 10 hours to form a mixed solution; then add 10 parts of polymer to the mixed solution Dimethylsiloxane was stirred and the pH was tested with PH test paper. The result showed that it was alkaline. Add phosphoric acid solution to make the pH neutral. The mixed solution is allowed to stand for 3 hours, and filtered through filter paper to obtain the emulsified working solution for high-efficiency wire cutting.

Embodiment 2

[0029] Prepare the following components in parts by weight:

[0030] 10 parts of polyethylene glycol, 10 parts of monoethanolamine, 15 parts of PH regulator, 10 parts of sodium citrate, 10 parts of s-triazine, 35 parts of triisopropanolamine.

[0031] Under the condition of constant stirring, add water-soluble lubricant, buffer emulsifier, rust inhibitor, fungicide, and grinding aid to deionized water in sequence, and stir for 10 hours to form a mixed solution; then add 5 parts of poly to the mixed solution Dimethylsiloxane was stirred and the pH was tested with a PH test paper. The result showed that it was acidic. Add potassium hydroxide solution to make the pH neutral. The mixed solution is allowed to stand for 3 hours, and filtered through filter paper to obtain the emulsified working solution for high-efficiency wire cutting.

[0032] 10-20 parts of water-soluble lubricant, 5-10 parts of organic silicon defoamer, 10-20 parts of buffer emulsifier, 10-15 parts of PH regulator, 5-...

Embodiment 3

[0034] Prepare the following components in parts by weight:

[0035] 15 parts of polyethylene glycol, 15 parts of monoethanolamine, 12 parts of PH regulator, 8 parts of sodium citrate, 12 parts of s-triazine, 30 parts of triisopropanolamine.

[0036] Under the condition of constant stirring, add water-soluble lubricant, buffer emulsifier, anti-rust agent, bactericide, and grinding aid to deionized water successively, and stir for 10 hours to form a mixed solution; then add 8 parts of poly into the mixed solution Dimethylsiloxane was stirred and the pH was tested with a PH test paper. The result showed that it was acidic. Add potassium hydroxide solution to make the pH neutral. The mixed solution is allowed to stand for 3 hours, and filtered through filter paper to obtain the emulsified working solution for high-efficiency wire cutting.

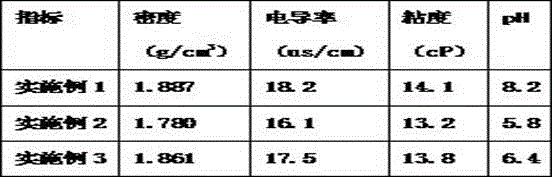

[0037] The tested indexes of the emulsified working fluid for cutting prepared in the above embodiments are shown in Table 1 below.

[0038] Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com