Energy saving and environmental protecting equipment and process for reducing white smoke in flue gas

An energy-saving, environmental-friendly, flue gas technology, which is applied in the direction of combustion equipment, lighting and heating equipment, non-flammable liquid/gas transportation, etc., can solve problems such as failure, white smoke from the chimney, etc., and achieve low resistance and small pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

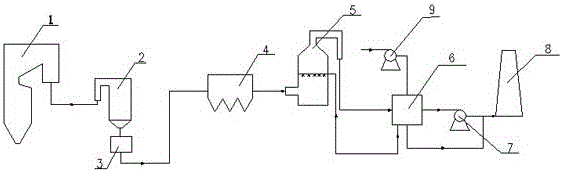

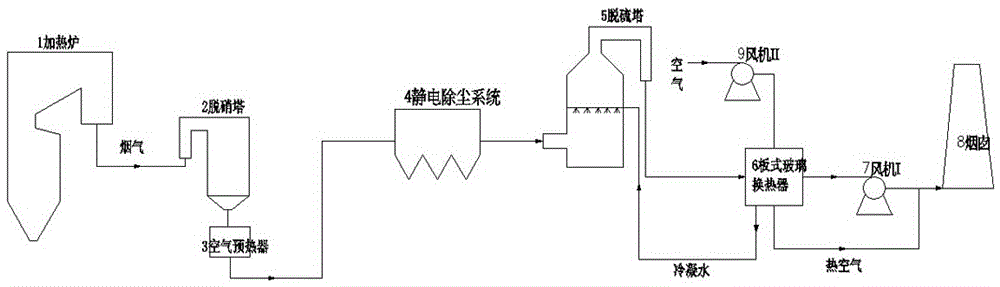

[0030] Such as Figure 1-3 As shown, an energy-saving and environment-friendly equipment for reducing flue gas white smoke, the equipment includes a boiler 1, followed by a denitrification tower 2, an air preheater 3, an electrostatic precipitator system 4, a desulfurization tower 5, and a fan 7 and chimney 8; behind the desulfurization tower 5, there is a glass plate heat exchanger 6, and the inlet positions of the glass plate heat exchanger 6 are respectively connected with fans for sending air at normal temperature 9 and the outlet of desulfurization tower 5; fan 7 is located at the outlet of the glass plate heat exchanger 6; the glass plate heat exchanger 6 is connected with a condensed water discharge pipe extending to the desulfurization tower 5 or the sewage treatment place.

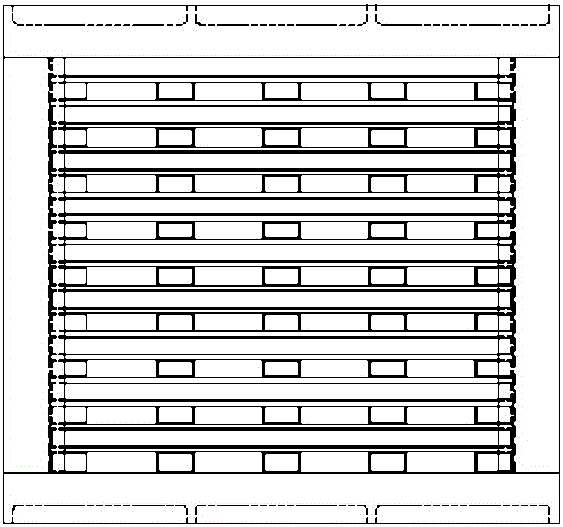

[0031] Further, the glass plate heat exchanger 6 is a cross flow, and the flow direction of the hot and cold medium is 90°.

[0032] Using the energy-saving and environment-friendly equipment...

Embodiment 2

[0039] An energy-saving and environment-friendly equipment for reducing flue gas white smoke, the equipment includes a boiler 1, followed by a denitrification tower 2, an air preheater 3, an electrostatic dust removal system 4, a desulfurization tower 5, and a fan 7 and chimney 8; behind the desulfurization tower 5, there is a glass plate heat exchanger 6, and the inlet positions of the glass plate heat exchanger 6 are respectively connected with fans for sending air at normal temperature 9 and the outlet of desulfurization tower 5; fan 7 is located at the outlet of the glass plate heat exchanger 6; the glass plate heat exchanger 6 is connected with a condensed water discharge pipe extending to the desulfurization tower 5 or the sewage treatment place.

[0040] Further, the glass plate heat exchanger 6 is a cross flow, and the flow direction of the hot and cold medium is 90°.

[0041] Further, the fan 9 can be replaced by an induced draft fan arranged behind the glass pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com