Waterborne ink for planographic press and preparation method thereof

A printing machine, water-based technology, applied in the direction of ink, application, household utensils, etc., can solve the problems of water-based ink production and use less, achieve fast printing speed, fast drying, and overcome the effect of slow drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

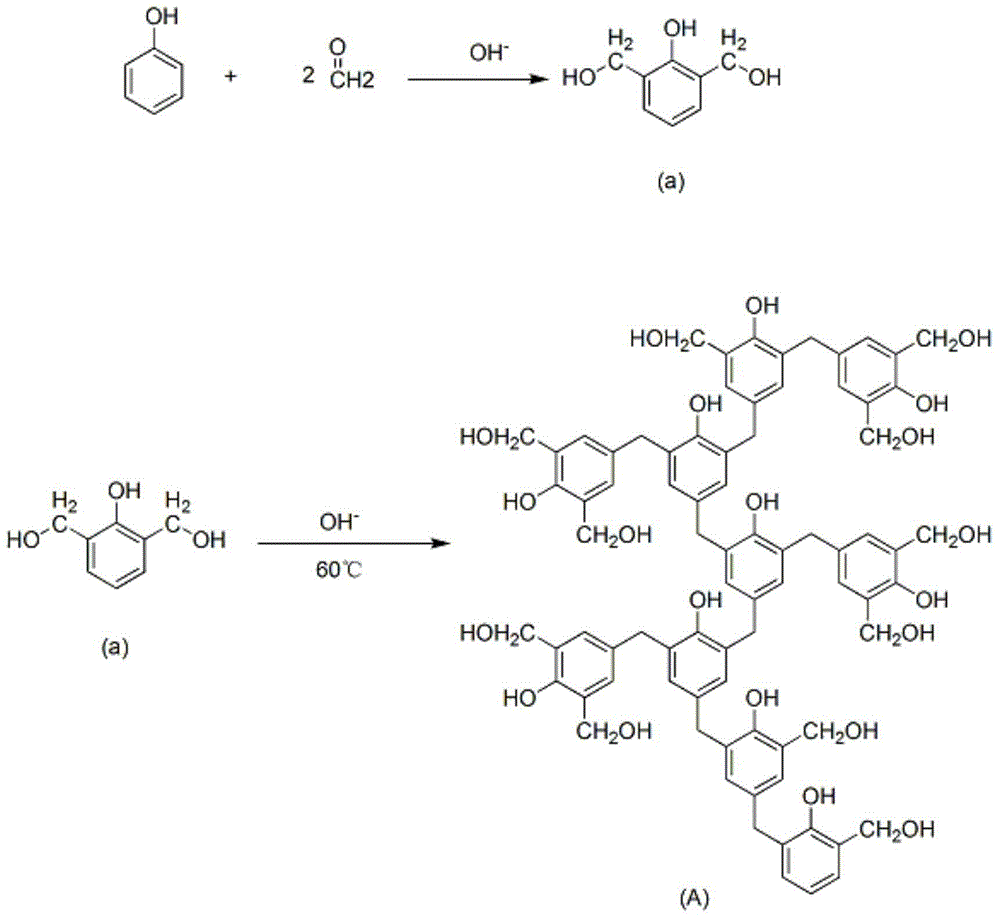

[0016] Preparation of monomer dimethylolphenol a: Take phenol and put it into a three-necked flask, add water with 4 times the mass of phenol and stir to dissolve, add formaldehyde (37% aqueous solution) with 2 times the mole of phenol and stir evenly, add 10% of the total solution mass Sodium hydroxide is catalyzer, stirred and reacted at room temperature for 12 hours, after the reaction (thin-layer chromatography can be used to monitor the reaction process), dilute hydrochloric acid is added to neutralize to neutrality, and after extraction with ethyl acetate, monomer a (dimethylolphenol ).

[0017] Preparation of hyperbranched hydroxymethylphenol A: monomer a is configured into a 10% (mass percent) ethanol solution, adding 4% of the total solution mass of ammonia as a catalyst, heated at 60°C for 6 hours to obtain hyperbranched polymer A (hyperbranched Hydroxymethyl phenol), after measuring, number average molecular weight 1100, weight average 3350, degree of branching 80%....

Embodiment 2

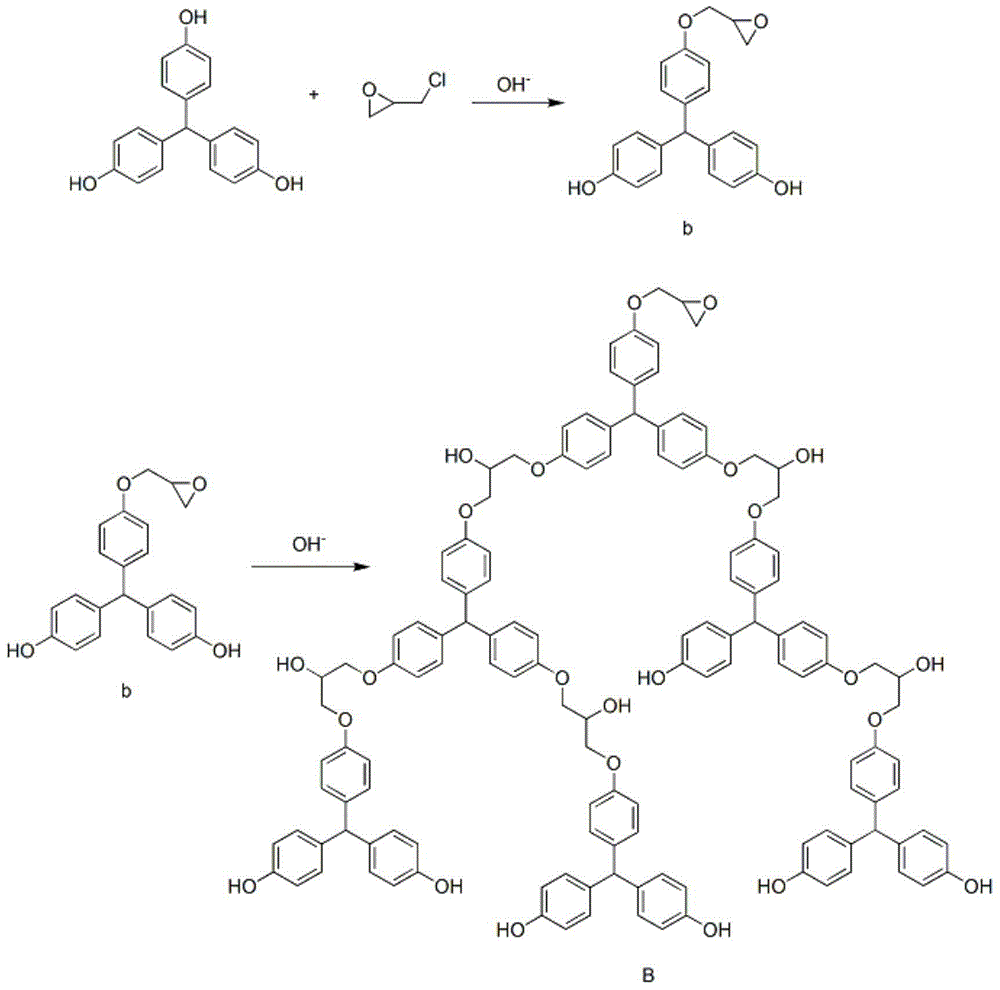

[0021] Preparation of (4-((4-hydroxyphenyl)(4-((oxiran-2-yloxy)methyl)phenyl)methyl)phenol)dihydroxyepoxy b: Take trihydroxytrimethylbenzene and add it to a three-necked flask, add trihydroxytrimethylbenzene 1 times of water and 3 times of tetrahydrofuran were stirred and dissolved, and equimolar epichlorohydrin was added to trihydroxytrimethylbenzene and stirred evenly, and sodium hydroxide accounting for 5% of the total solution mass was added, and stirred and reacted at room temperature for 6 hours. After the reaction ( The reaction process can be monitored by thin-layer chromatography), vacuum distillation, and extraction with ethyl acetate to obtain monomer b (dihydroxyl epoxy).

[0022] The preparation method of hyperbranched polyhydroxy epoxy B: the monomer b is configured into a 10% (mass percentage) ethanol solution, adding 1% of the total solution mass of sodium hydroxide as a catalyst, and heating at 60°C for 4 hours to obtain a hyperbranched polymer B (hyperbranche...

Embodiment 3

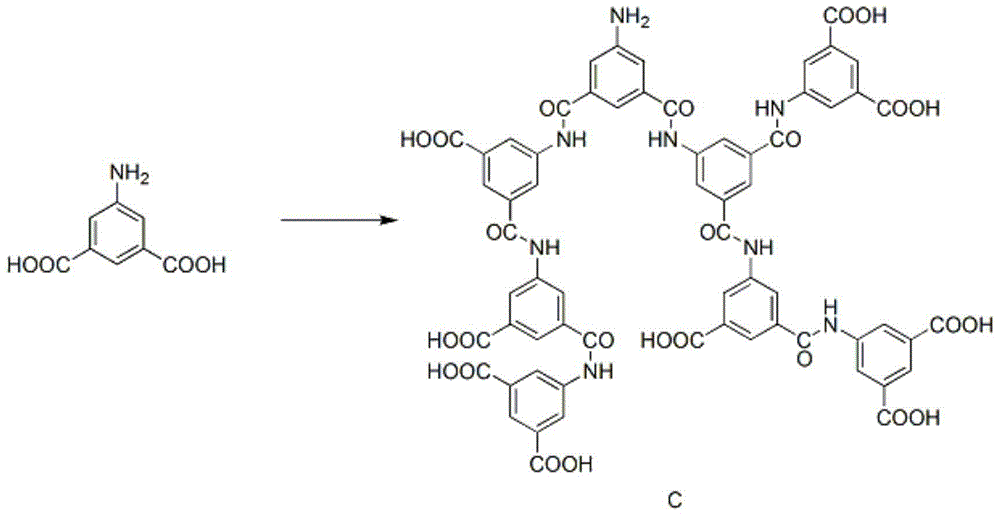

[0026] The preparation method of hyperbranched polyamide C: take aminoisophthalic acid and put it into a three-necked flask, add 1 times its mass of water and 3 times its mass of ethanol and stir to dissolve, heat at 60°C, stir and react for 6 hours, after the reaction is finished (you can use a thin The reaction process is monitored by layer chromatography), distillation under reduced pressure, and extraction with ethyl acetate to obtain hyperbranched polymer C (hyperbranched polyamide). After measurement, the number average molecular weight is 1020, the weight average is 5900, and the degree of branching is 75%.

[0027]

[0028] Get 60 parts (mass) of the hyperbranched polyamide (C) prepared above, under the rotating speed>600r / min, 10 parts of nano silicon dioxide (mass), 20 parts of red organic dye (mass), 10 parts of water (mass) , disperse at high speed and fully wet the powder, grind on a three-roller machine, and the fineness is <10μm, that is, water-based ink for l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com