Metal thin film filtering capacitor for frequency converter

A filter capacitor and metal film technology, applied in the field of filters, can solve problems such as lifespan, and achieve the effects of long service life, high breakdown electric field strength, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

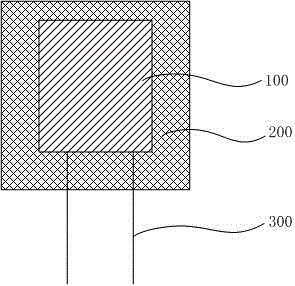

[0025] see figure 1 , a metal film filter capacitor for frequency converters, which includes a core set 100, an encapsulation layer 200 and pins 300, wherein the encapsulation layer 200 is wrapped around the core set 100, that is to say, the core set 100 is entirely wrapped in the encapsulation layer In 200 , pins 300 are connected to the core pack and protrude from the packaging layer 200 .

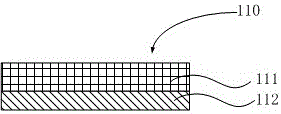

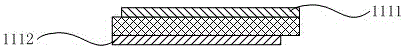

[0026] see further figure 2 The core set 200 in this embodiment is formed by winding at least one set of film layers 110, and there may be multiple sets of film layers, and multiple sets of film layers are stacked and wound to form a core set. The film layer 110 includes a double-sided metall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com