A high thermal conductivity flame retardant polyethylene-based composite material and its preparation method

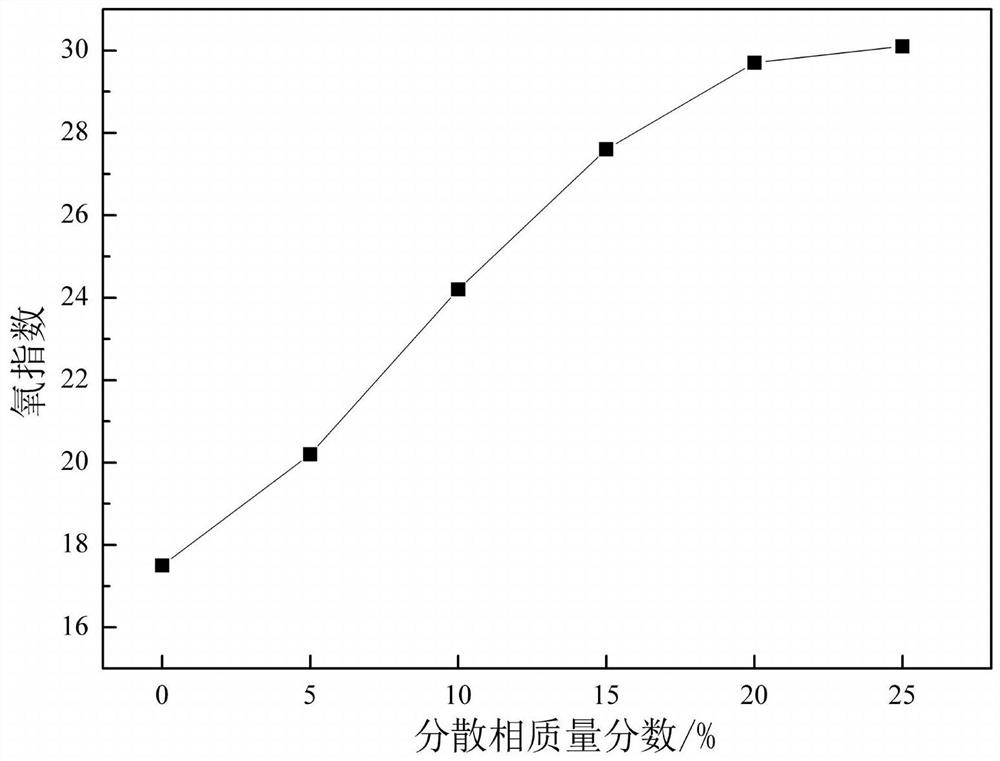

A technology of flame-retardant polyethylene and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, plastic/resin/wax insulators, etc., can solve the problems of poor thermal conductivity and flame retardancy of polyethylene, and achieve improved flame retardancy and The effect of thermal conductivity, excellent insulation performance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a high thermal conductivity flame-retardant polyethylene-based composite material, comprising the following steps:

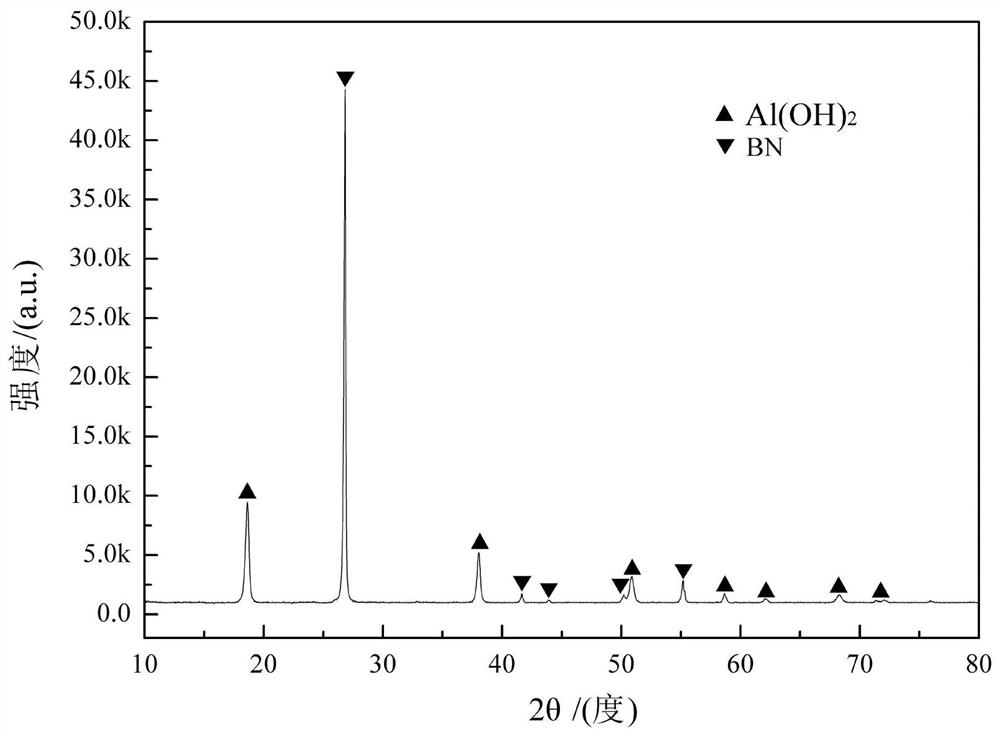

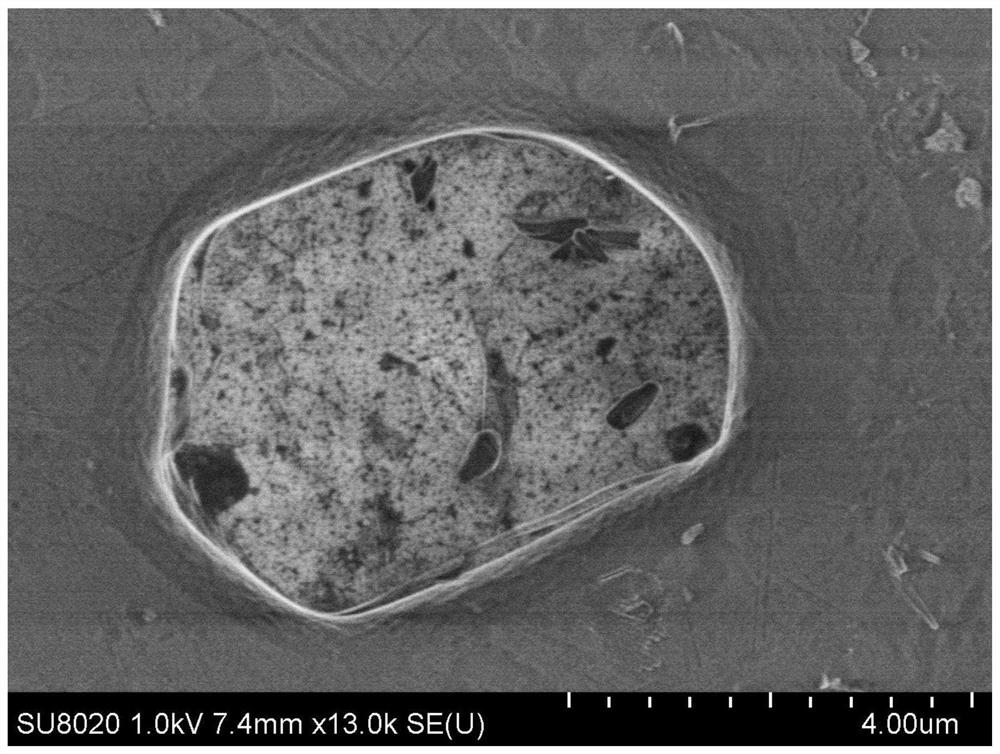

[0032] S1: Weigh the Al(OH) prepared by the sol-gel method according to the mass ratio of 1:1 3 Zero-dimensional powder and the purchased BN two-dimensional sheet, that is, hexagonal boron nitride two-dimensional sheet, the two powders are placed in a mixed liquid of absolute ethanol and ionic water with a volume ratio of 1:0.75, and an ultrasonic disperser is used to Disperse and strip the mixed powder with 600W ultrasonic for 24 hours, then stir the mixed liquid with a magnetic stirrer at room temperature at a speed of 600r / min for 1 hour, and finally use a centrifuge to centrifuge at a high speed of 10000r / min for 10min, and the obtained mixed powder The body is dried and ground for use;

[0033] S2: Put the mixed powder prepared in step S1 in a beaker, then measure an appropriate amount of absolute ethanol and place it in the b...

Embodiment 2

[0039] A method for preparing a high thermal conductivity flame-retardant polyethylene-based composite material, comprising the following steps:

[0040] S1: Weigh 1.2g of Al(OH) by sol-gel method 3 Zero-dimensional powder and 1.2g of purchased BN two-dimensional tablets, the two powders were placed in a mixed liquid of 30mL of absolute ethanol and 20mL of ionic water, and the mixed powder was subjected to 600W ultrasound for 24h using an ultrasonic disperser. Disperse and peel off, then use a magnetic stirrer to stir the mixed liquid at room temperature at a speed of 600r / min for 1h, and finally use a centrifuge to centrifuge at a high speed of 10000r / min for 10min, and dry and grind the obtained mixed powder for use;

[0041]S2: Put the mixed powder prepared in step S1 in a beaker, then measure 50mL of absolute ethanol and place it in the beaker, place the beaker on a magnetic stirrer and stir evenly for a period of time, then add 0.24g of amino functional silane (KH550 ), ...

Embodiment 3

[0047] A method for preparing a high thermal conductivity flame-retardant polyethylene-based composite material, comprising the following steps:

[0048] S1: Weigh the Al(OH) prepared by the sol-gel method according to the mass ratio of 1:0.2 3 Zero-dimensional powder and the purchased BN two-dimensional sheet, that is, hexagonal boron nitride two-dimensional sheet, the two powders are placed in a mixed liquid of absolute ethanol and ionic water with a volume ratio of 1:0.75, and an ultrasonic disperser is used to Disperse and strip the mixed powder with 550W ultrasound for 20 hours, then stir the mixed liquid with a magnetic stirrer at room temperature at a speed of 600r / min for 1h, and finally use a centrifuge to centrifuge at a high speed of 8000r / min for 10min, and mix the obtained mixed powder body drying and grinding for later use, wherein the mass ratio of the two-dimensional hexagonal boron nitride sheet to deionized water is 1:4.5;

[0049] S2: Put the mixed powder p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com