Gallium nitride Schottky barrier diode with vertical structure and manufacturing method thereof

A Schottky potential and vertical structure technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high current path resistance, difficult to obtain high current devices, complex manufacturing process, etc., and achieve leakage current Effect of small size, few defects, and low leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

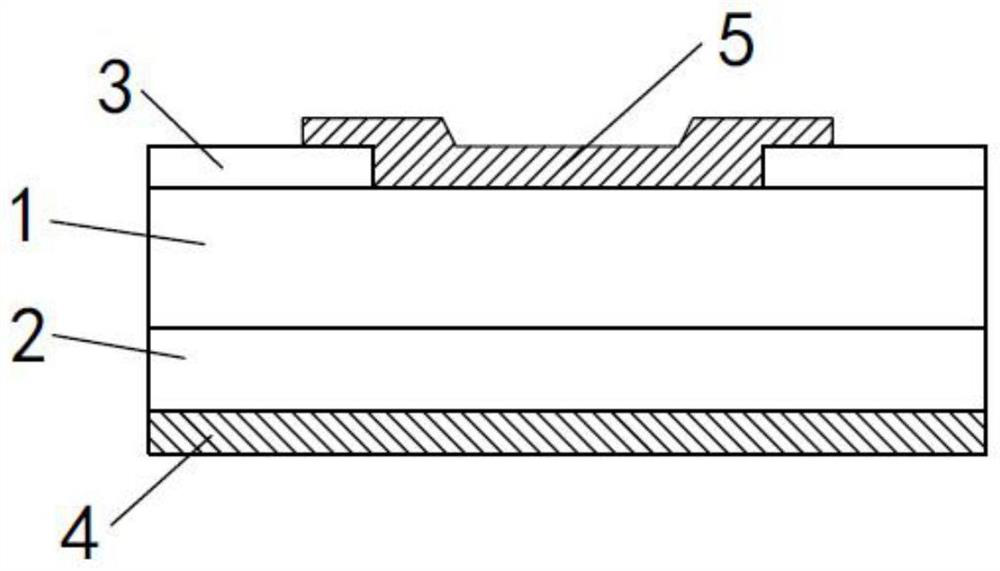

[0046] the n - -GaN layer 1 is n - -GaN substrate layer, the n + -GaN layer 2 is n + - GaN epitaxial layer.

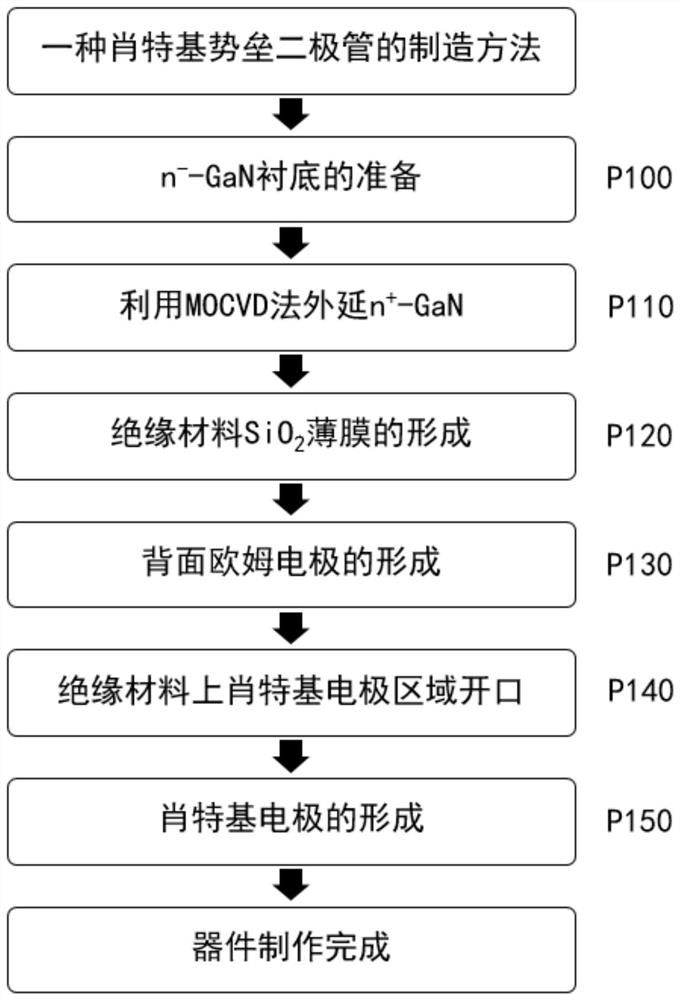

[0047] The fabrication method of the gallium nitride Schottky barrier diode with vertical structure specifically includes the following steps:

[0048] P100:n - -GaN substrate preparation

[0049] 2 inches in diameter, 430 microns thick, (0001) surface, mirror polished n on both sides - -GaN single crystal is used as the substrate layer, and the impurity concentration is 1×10 16 cm -3 , the carrier mobility is at 650cm 2 / VS.

[0050] P110: Epitaxy n by MOCVD + -GaN

[0051] First, the two mirror-polished n - -GaN substrate layer 1 is put into the reaction furnace of MOCVD equipment, in the reaction furnace of MOCVD equipment, import hydrogen (H 2 ) and nitrogen (N 2 ), the flow ratio of hydrogen gas and nitrogen gas can be set in the range of 10:(10~0), heat the substrate to 1100°C and keep it warm for 5~10 minutes, for n - - The surface of the GaN subs...

Embodiment 2

[0075] the n - -GaN layer 1 is n - -GaN epitaxial layer, the n + -GaN layer 2 is n + -GaN substrate layer.

[0076] The fabrication method of the gallium nitride Schottky barrier diode with vertical structure specifically includes the following steps:

[0077] Present embodiment adopts diameter 2 inches, thickness 325 microns, (0001) face, the n of two-sided mirror polishing + -GaN single crystal is used as the substrate layer, and the impurity concentration is 2×10 18 cm -3 , the carrier mobility is at 500cm 2 / VS.

[0078] First, the two mirror-polished n + -GaN single crystal substrate is placed in the reaction furnace of MOCVD equipment, and hydrogen gas (H 2 ) and nitrogen (N 2 ), the flow ratio of hydrogen gas and nitrogen gas can be set in the range of 10:(10~0), heat the substrate to 1100°C and keep it warm for 5~10 minutes, for n + -The surface of the GaN substrate is cleaned at high temperature.

[0079] Then, put n + -The temperature of the GaN substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com