A kind of solid-state dielectric film capacitor with high energy storage density and preparation method thereof

A high energy storage density, film capacitor technology, applied in the direction of film/thick film capacitors, electrolytic capacitors, fixed capacitor electrodes, etc. The effect of high dielectric constant, high breakdown electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

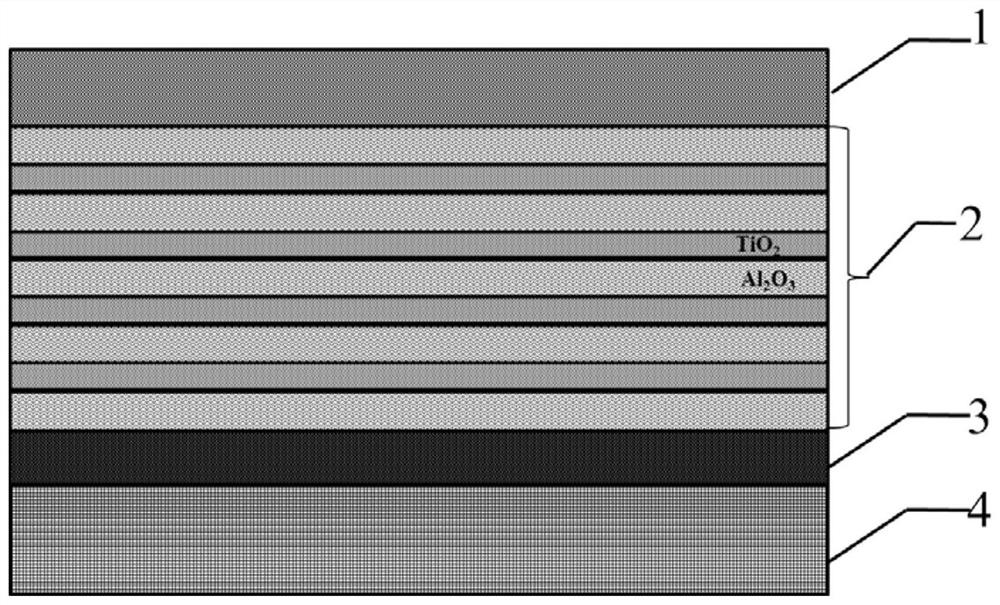

[0023] The solid film capacitor with high energy storage density prepared in this embodiment includes a substrate substrate, a bottom electrode, an aluminum oxide / titania composite dielectric film and an upper electrode. Capacitor cross section such as figure 1 As shown, in the figure, 1 is the upper electrode metal Ti film, 2 is the aluminum oxide / titania composite dielectric film, 3 is the bottom electrode metal Pt film, and 4 is the substrate silicon wafer.

[0024] The preparation of the high-density energy storage solid film capacitor comprises the following steps:

[0025] (1) adopt the method for magnetron sputtering to prepare Pt thin film on silicon substrate as bottom electrode;

[0026] (2) Dissolve 0.01mol of aluminum nitrate nonahydrate into 20ml of glacial acetic acid, heat and stir in a water bath at 70°C for 30min, then add 4ml of acetic anhydride, stir at 60°C for 30min, cool naturally to room temperature, and add appropriate amount of acetylacetone, Al 3+ T...

Embodiment 2

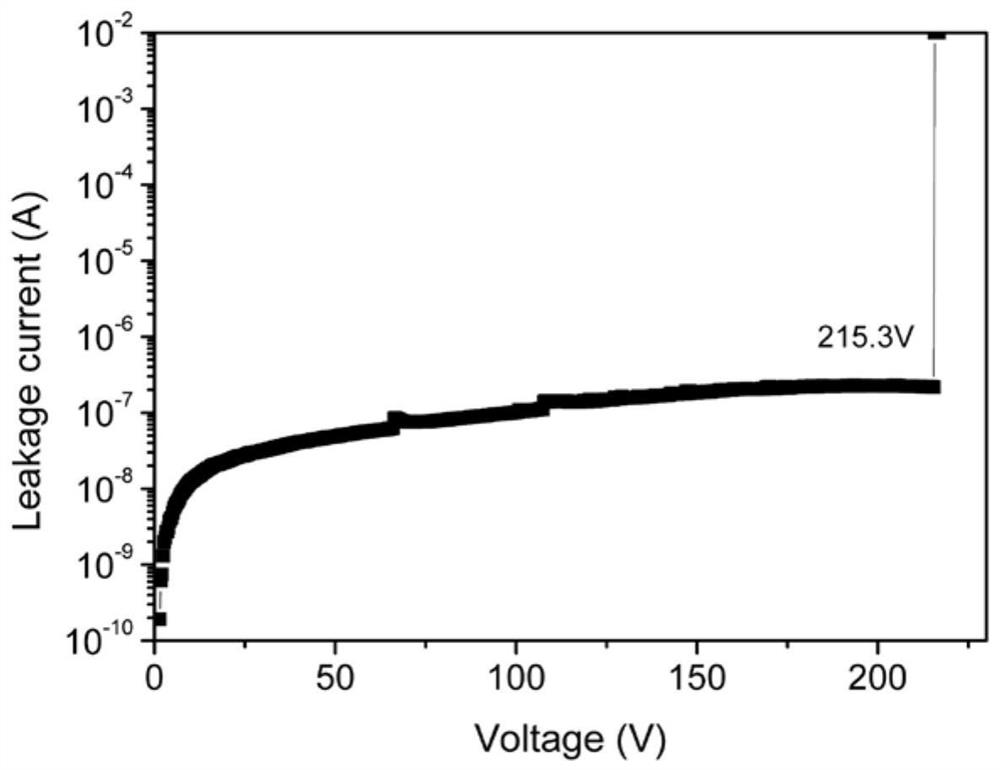

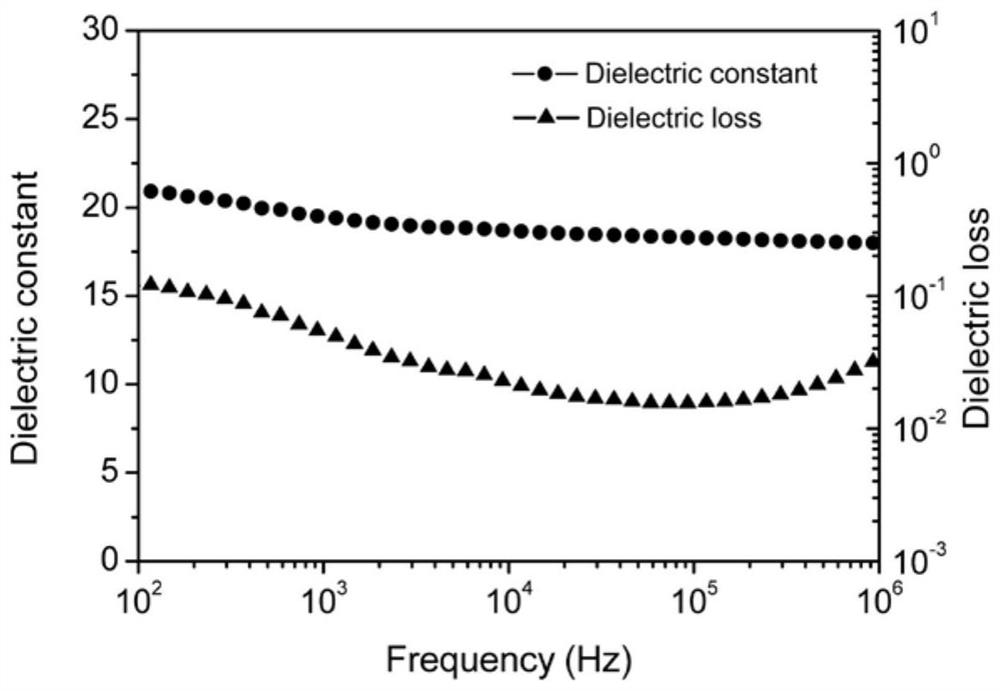

[0035] In this embodiment, the thickness of each layer of Ti metal film deposited by pulsed laser is increased, and the conditions of other experimental steps are the same as those in Embodiment 1. The composite dielectric film consists of 5 layers of aluminum oxide and 4 layers of titanium dioxide in sequence. The thickness of each layer of aluminum oxide film is 60nm, and the thickness of each layer of titanium dioxide film is 22.5nm. 390nm. The breakdown electric field strength of the dielectric film is 574MV / m, the dielectric constant is 17.6, and the energy storage density is as high as 25.7J / cm 3 .

Embodiment 3

[0037] In the present embodiment, adopt step (2) process preparation Al in embodiment 1 3+ Concentration is the aluminum oxide precursor of 0.3mol / L, all the other experimental procedure conditions are the same as embodiment 1, the composite dielectric thin film has 5 layers of aluminum oxide and 4 layers of titanium dioxide alternately successively to form, the thickness of each layer of the prepared aluminum oxide film is 40nm, titanium dioxide The thickness of each layer of the film is 15nm, and the thickness of the aluminum oxide / titania composite dielectric film in this example is about 260nm. The breakdown electric field strength of the dielectric film is 561MV / m, the dielectric constant is 18.2, and the energy storage density is as high as 25.4J / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com