A device and method for separating and collecting materials of all components of waste lithium batteries

A waste lithium battery and collection device technology, applied in the battery field, can solve the problems of complex recycling process, introduction of a large number of chemical reagents, low processing efficiency of recycling processing equipment, etc., to achieve the effect of high recycling efficiency and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

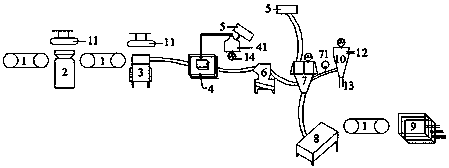

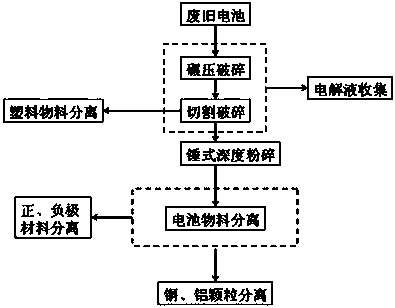

[0040] Such as figure 1 As shown, a material separation and collection device for all components of waste lithium batteries, which includes a roller crusher 2 and a knife crusher 3 connected by an electric conveyor belt 1, and a plastic crusher connected to the knife crusher 3 in sequence through a pipeline A material separation and collection device, a hammer mill 6 and a battery material separation device; an electrolyte adsorption and collection device 11 is provided above the roller crusher 2 and the knife crusher 3;

[0041] The plastic material separation and collection device includes a dense first vibrating screen 4, the first vibrating screen 4 is a sealed structure, the top of the first vibrating screen 4 is connected with a plastic material storage bin 41 through a pipeline, and the plastic material storage bin 41 is connected with a A dust collection device 5 is provided above the vacuum pump 14 and the plastic material storage bin 41;

[0042] The battery materia...

Embodiment 2

[0055] A method and device for recycling waste lithium batteries, comprising the following steps:

[0056] Take 300kg of waste energy storage lithium batteries, the battery type is lithium iron phosphate battery, the specification is 180Ah square steel shell battery, and the external dimensions are 178 mm×278 mm×70mm. Carry out recycling according to the following method steps.

[0057]Other contents and operations are the same as in Example 1, except that in step (1), the rolling force is between 3000 Newton and 5000 Newton, and the primary debris material with a particle size of 30-40 mm is obtained after rolling and crushing. In step (2), the knife crusher 3 rotates at a speed of 2000 rpm, and the primary debris material contacts the cutter head of the high-speed rotating knife crusher 3 at an angle of 70 degrees, and the particle size of the obtained secondary debris material is The diameter size is 2-5mm. During the crushing, cutting and crushing process, the electrolyt...

Embodiment 3

[0059] A method and device for recycling waste lithium batteries, comprising the following steps:

[0060] Take 200kg of waste laptop lithium batteries, the battery type is lithium cobalt oxide battery, the specification is 3000mAh square cylindrical battery, the external dimensions are 18mm in diameter and 65mm in height. Carry out recycling according to the following method steps.

[0061] Other contents and operations are the same as in Example 1, except that in step (1), the rolling force is between 3000 Newton and 4000 Newton, and the primary debris material with a particle size of 25-40 mm is obtained after rolling and crushing. In step (2), the knife crusher 3 rotates at a speed of 1800 rpm, and the primary debris material contacts the cutter head of the high-speed rotating knife crusher 3 at an angle of 45 degrees, and the particle size of the obtained secondary debris material is The diameter size is 15-20mm. During the crushing, cutting and crushing process, the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com