Microfluid self-driven paper base micro-fluidic chip and preparation method and application thereof

A microfluidic chip, self-driven technology, applied in chemical instruments and methods, laboratory containers, analysis by making materials undergo chemical reactions, etc., can solve the problem of low processing precision and cannot meet the requirements of complex microfluidic systems and other problems to achieve the effect of simplifying auxiliary equipment and solving the lack of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 The preparation method of the microfluidic self-driven paper-based microfluidic chip described in the present invention comprises the following steps:

[0032] 1) Preparation of superhydrophobic titanium dioxide coating solution: mix 0.1g titanium dioxide powder with 10mL absolute ethanol, and then ultrasonicate at 100Hz for 30min to form a 0.01g / mL titanium dioxide suspension, then add 0.2mL octadecyltrimethoxy Silane, continue to ultrasonically mix under the condition of 100Hz, and then react at room temperature for 12h to obtain a superhydrophobic titanium dioxide coating solution; the volume ratio of the octadecyltrimethoxysilane to the titanium dioxide suspension is 0.02:1;

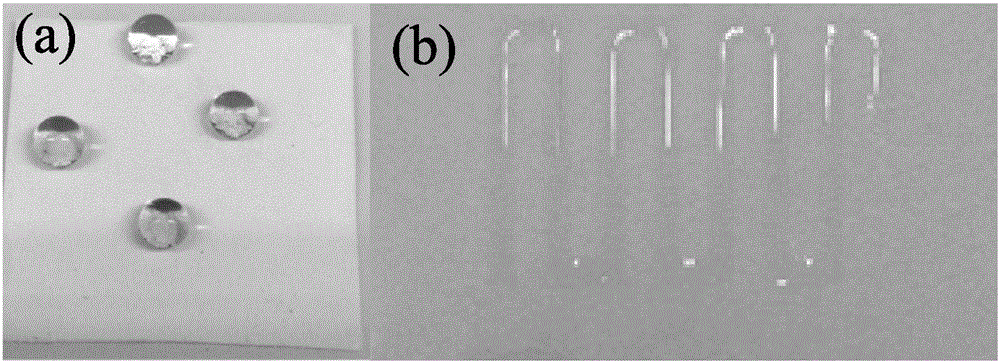

[0033] 2) Preparation of superhydrophobic filter paper: Soak a filter paper sheet with a diameter of 9 cm in the above-mentioned superhydrophobic titanium dioxide coating solution for 5 minutes, take it out, and dry it naturally at room temperature; repeat the operation 3 times to ...

Embodiment 2

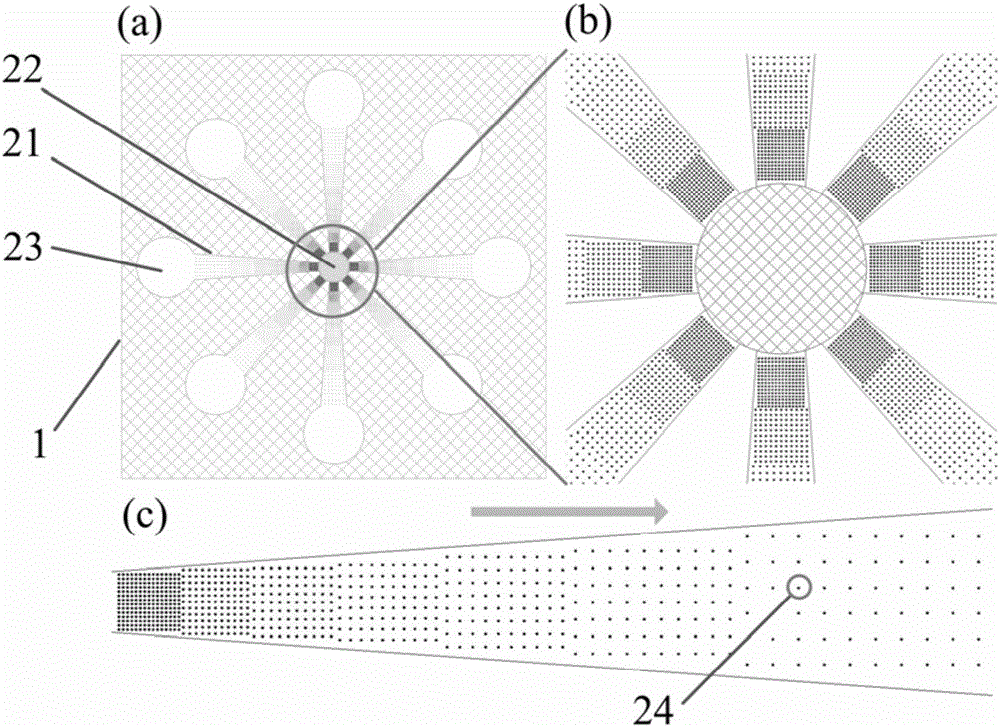

[0036] Example 2 The microfluidic chip prepared according to the preparation method described in Example 1, comprising a filter paper 1, a hydrophilic-hydrophobic layer 2 coated on the surface of the filter paper, and the hydrophilic-hydrophobic layer 2 is provided with at least one gradient moistening layer. The hydrophilic flow channel 21 on the wet surface; one end of the hydrophilic flow channel 21 is used as the sample loading area 22, and the other end is used as the detection area 23; the hydrophilic flow channel 21 is divided into multiple areas from the sample loading area 22 to the detection area 23 , a number of hydrophobic patterns 24 are evenly distributed in each region, and the corresponding position of each hydrophobic pattern 24 corresponding to the substrate is a superhydrophobic region, and the region outside the hydrophobic pattern is a superhydrophilic region; along the direction from the sample application region to the detection region, the The number of ...

Embodiment 3

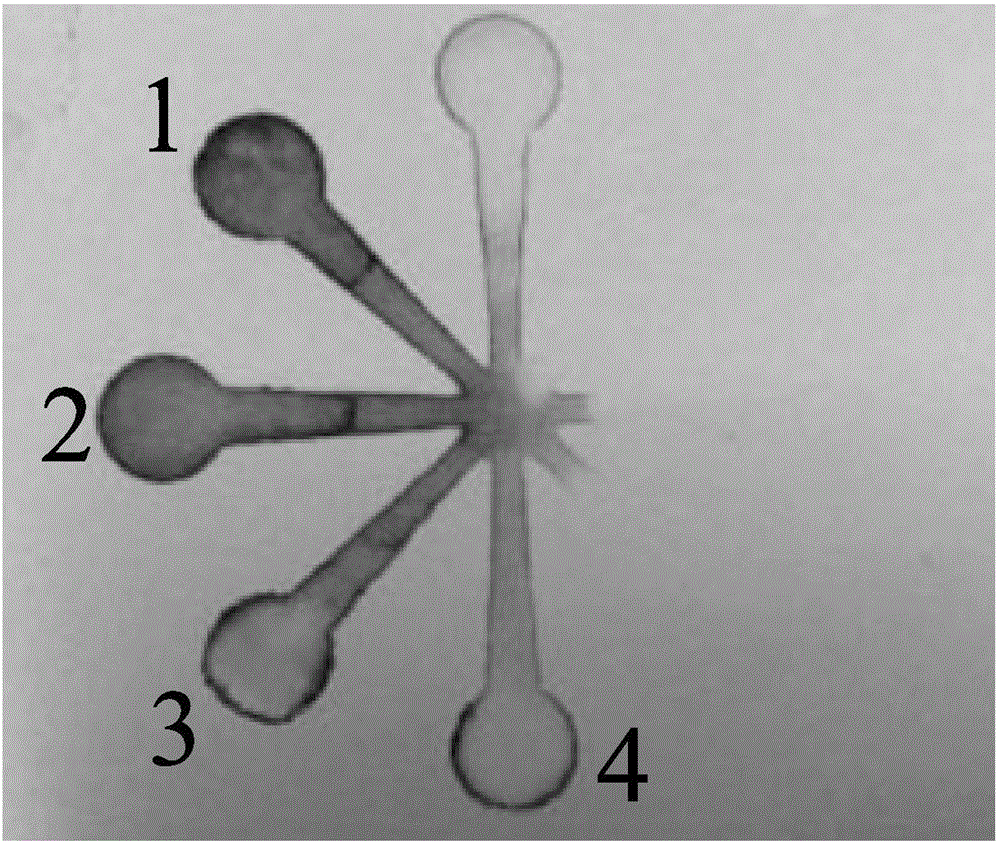

[0039] Embodiment 3 According to the application of the microfluidic chip described in embodiment 2 in the detection of hydrogen peroxide, the described application method is carried out according to the following steps:

[0040] (1) will 8x10 -4 M, 4x10 -4 M, 1x10 -4 M, 0.1x10 -4 Four different concentrations of potassium iodide are loaded in the detection area, and 3% hydrogen peroxide is dropped into the sampling area of the tested sample. The hydrogen peroxide droplets can quickly and automatically pass through the flow channel and reach the detected area. The potassium iodide in the detection area is oxidized by hydrogen peroxide. Color change; hydrogen peroxide droplets can quickly and automatically pass through the flow channel and reach the detected area. Potassium iodide is reduced to colored iodine by hydrogen peroxide. Different concentrations of potassium iodide show different color intensities after being reduced;

[0041] (2) Color grayscale processing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com