Method for improving quality of graphene directly grown on nonmetal substrate

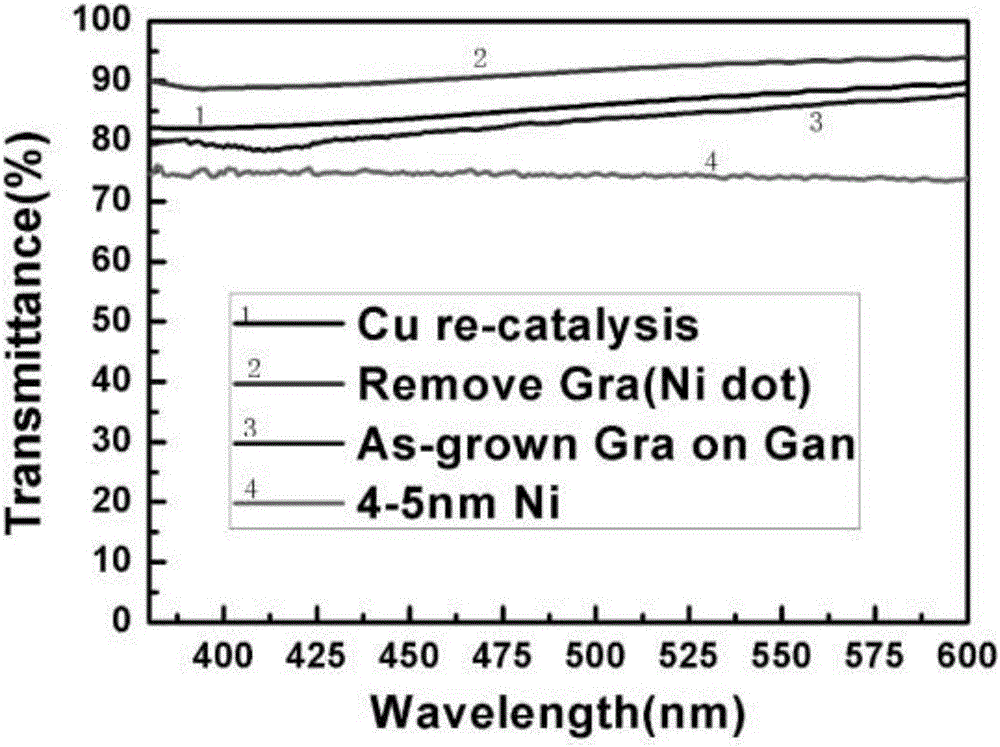

A graphene, non-metal technology, applied in the field of semiconductor material growth, to achieve the effects of good light transmittance, improved quality, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

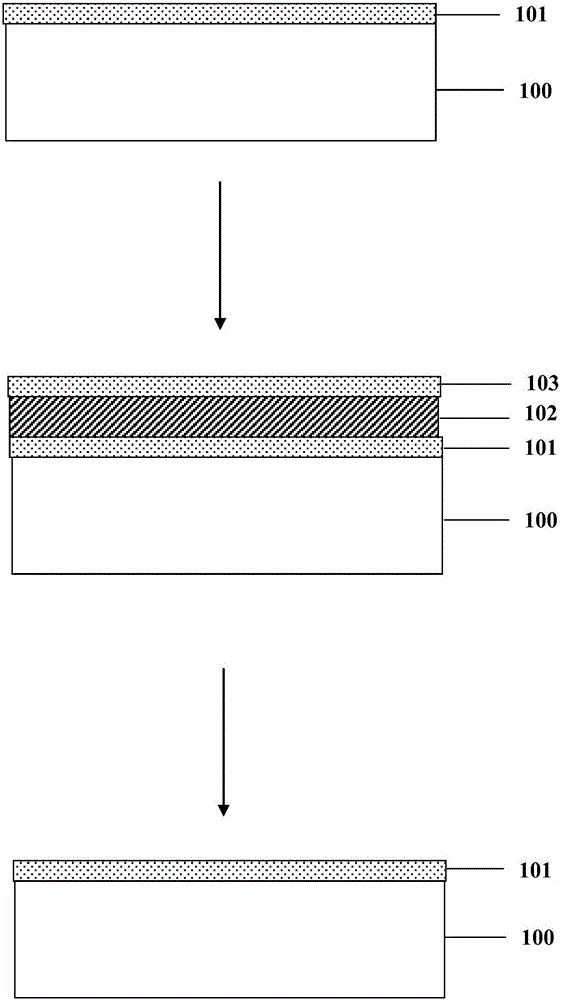

Method used

Image

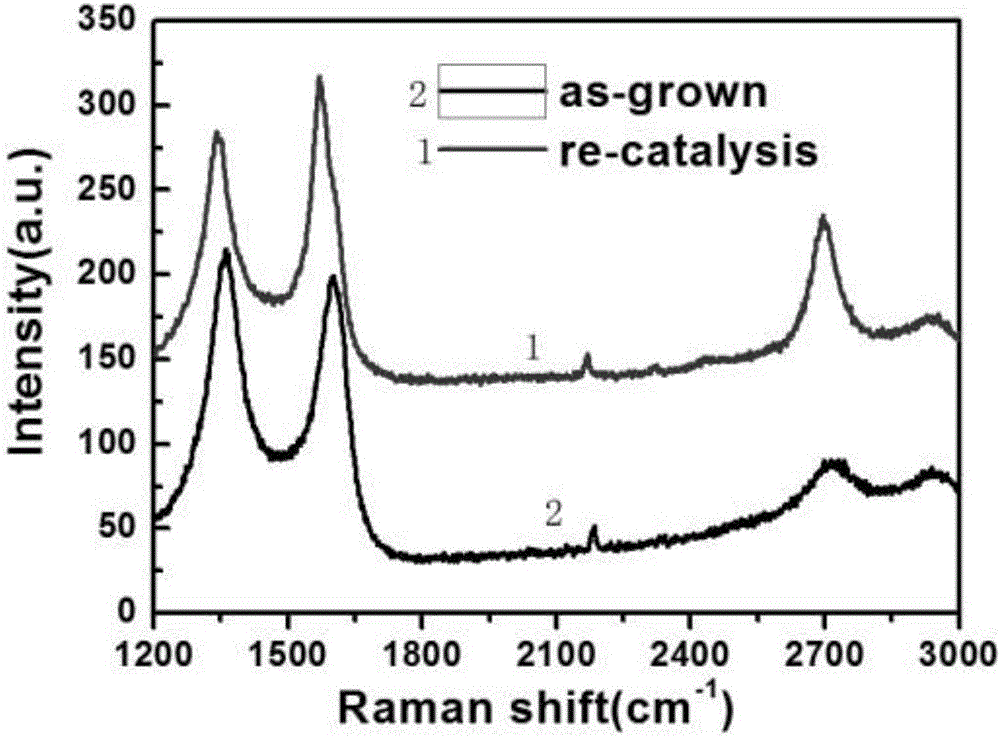

Examples

Embodiment 1

[0026] Step 1. Clean two GaN-based LED epitaxial wafers of the same batch, use acetone to ultrasonic for 5 minutes, boil with acetone, ethanol, and aqua regia in turn, wash with deionized water, and blow dry with nitrogen;

[0027] Step 2. Spin-coat photoresist on the surface of the epitaxial wafer, and use ICP etching technology to form a step structure to expose the n-GaN layer;

[0028] Step 3, PECVD deposition of SiO 2 , photolithography and etching with BOE to form SiO 2 barrier layer;

[0029] Step 4, sputtering a thin Ni layer with a thickness of 4-5nm on the surface as a catalytic layer;

[0030] Step 5. Put the epitaxial wafer into the CVD reaction chamber to grow graphene under the same conditions, the flow rate of argon gas is 960 sccm, the flow rate of hydrogen gas is 40 sccm, the flow rate of methane is 40 sccm, the growth temperature is 800°C, and the growth time is 5 minutes;

[0031] Step 6, growing 550nm Cu on the epitaxial wafer grown with graphene by magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com