A kind of preparation method of PVDC resin for inner printing film

A technology of resin and printing film, which is applied in the field of PVDC resin preparation for lining printing film, to achieve the effects of low haze, excellent product performance and strong layering of the picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of PVDC resin for printing membrane, comprises the following steps:

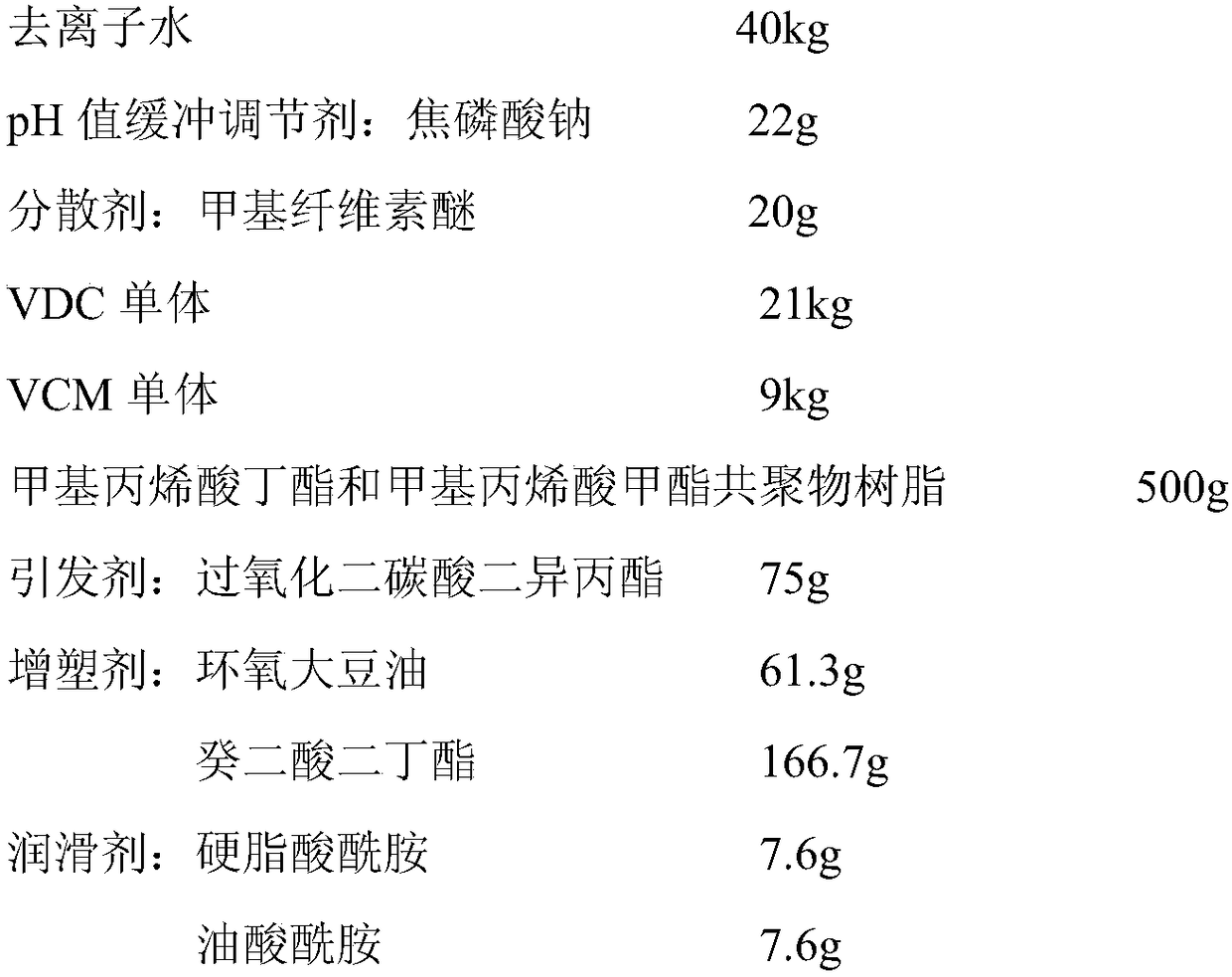

[0033] (1) Prepare the reaction raw materials for subsequent use, and the reaction raw materials consist of:

[0034]

[0035] (2) Preparation of pH value buffer regulator aqueous solution and dispersant aqueous solution: Sodium pyrophosphate 22g is mixed with deionized water 2kg to be formulated with pH value buffer regulator aqueous solution; Methyl cellulose ether 20g is mixed with deionized water 5kg with dispersant aqueous solution ;

[0036] (3) Add 5kg of deionized water into a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, double-layer two-page 45° inclined paddle), seal the kettle for pressure test and leak test, and add after vacuuming VDC monomer, VCM monomer, diisopropyl peroxydicarbonate, butyl methacrylate and methyl methacrylate copolymer resin, after dispersing at a speed of 90rpm...

Embodiment 2

[0041] A kind of preparation method of PVDC resin for printing membrane, comprises the following steps:

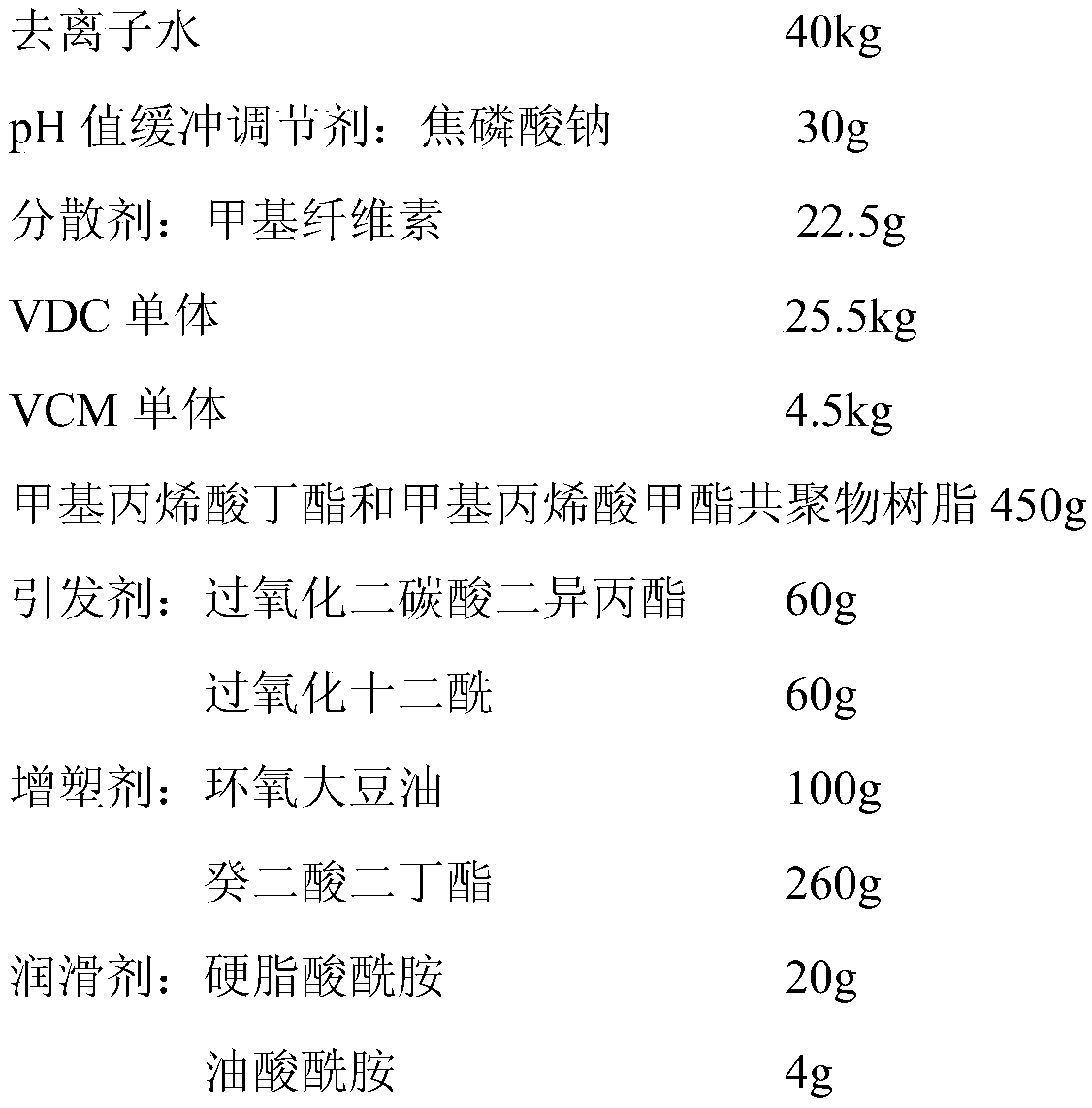

[0042] (1) Prepare the reaction raw materials for subsequent use, and the reaction raw materials consist of:

[0043]

[0044] (2) Preparation of pH value buffer regulator aqueous solution and dispersant aqueous solution: Sodium pyrophosphate 30g is mixed with deionized water 2kg to be formulated with pH value buffer regulator aqueous solution; With methyl cellulose 22.5g, is mixed with deionized water 5kg into dispersant aqueous solution;

[0045] (3) Add 5kg of deionized water into a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, double-layer two-page 45° inclined paddle), seal the kettle for pressure test and leak test, and add after vacuuming VDC monomer, VCM monomer, diisopropyl peroxydicarbonate, lauryl peroxide, butyl methacrylate and methyl methacrylate copolymer resin, after dispersing a...

Embodiment 3

[0050] A kind of preparation method of PVDC resin for printing membrane, comprises the following steps:

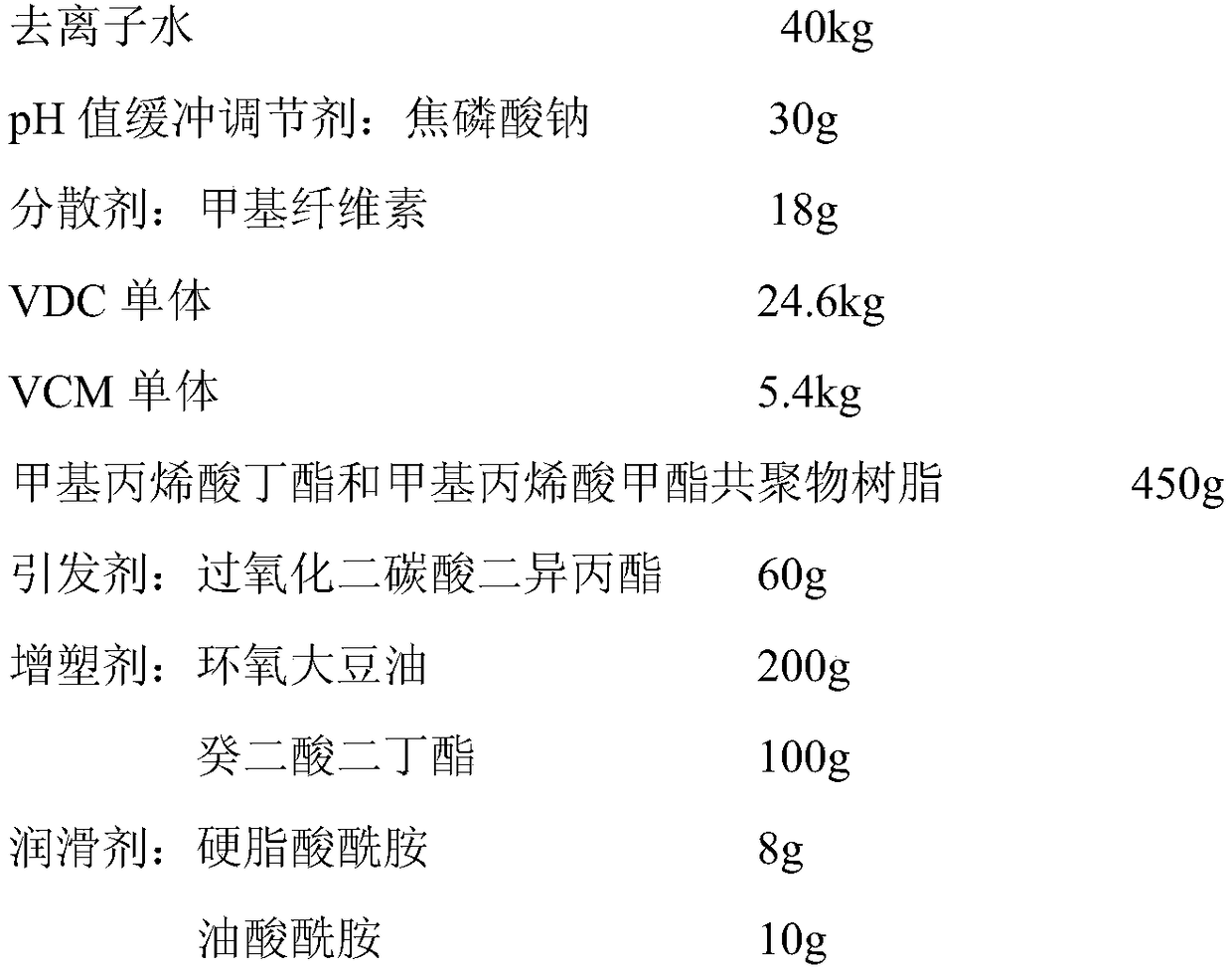

[0051] (1) Prepare the reaction raw materials for subsequent use, and the reaction raw materials consist of:

[0052]

[0053] (2) Preparation of pH value buffer regulator aqueous solution and dispersant aqueous solution: Sodium pyrophosphate 30g is mixed with deionized water 2kg to be mixed with pH value buffer regulator aqueous solution; With methylcellulose 18g, be mixed with deionized water 5kg to be mixed with dispersant aqueous solution ;

[0054] (3) Add 5kg of deionized water into a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, double-layer two-page 45° inclined paddle), seal the kettle and test the pressure and leak. After vacuuming, add VDC monomer, VCM monomer, diisopropyl peroxydicarbonate, butyl methacrylate and methyl methacrylate copolymer resin and disperse at 120rpm / min for 28 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com