Corrosion inhibitor for oilfield flooding and preparation method thereof

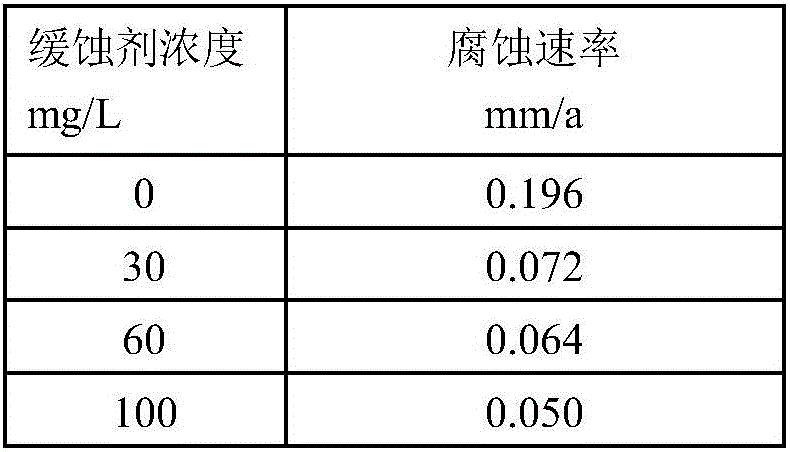

A technology of oilfield water injection and corrosion inhibitor, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of limited corrosion inhibition effect of corrosion inhibitor, difficult metal equipment and pipeline protection, etc., and achieve Good corrosion inhibition effect, choose low toxicity, and obvious corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The second aspect of the present invention provides the preparation method of above-mentioned oil field water injection corrosion inhibitor, and its step comprises:

[0018] A, prepare Mannich base quaternization derivative, its step comprises: get reaction raw material and join in the solvent, described reaction raw material is 2-mercaptobenzothiazole and benzaldehyde or 2-mercaptobenzothiazole and furfural, Or 2-mercaptobenzothiazole and cinnamaldehyde, stir, add aniline dropwise, adjust the system pH=2~3, react at 75~90°C for 4~10h, and obtain the Mannich base compound; cool to 50-70°C, drop Add benzyl chloride and continue the reaction for 2 to 3 hours to obtain the quaternized derivative of Mannich base;

[0019] B. Mix the quaternized derivative of Mannich base obtained in step A with acetylenic alcohol, alkali metal iodide, OP-10, urotropine and solvent in proportion.

[0020] Preferably, the molar ratio of the 2-mercaptobenzothiazole to furfural is 1.0:1.0-1.8;...

Embodiment 1

[0026] This embodiment provides a kind of corrosion inhibitor for oilfield water flooding, and its preparation step comprises the following steps:

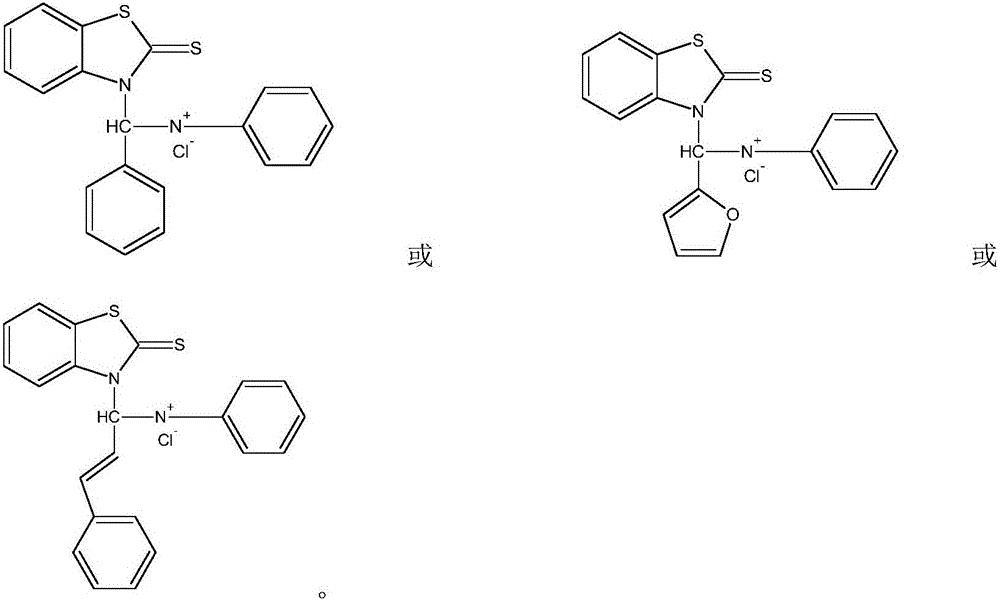

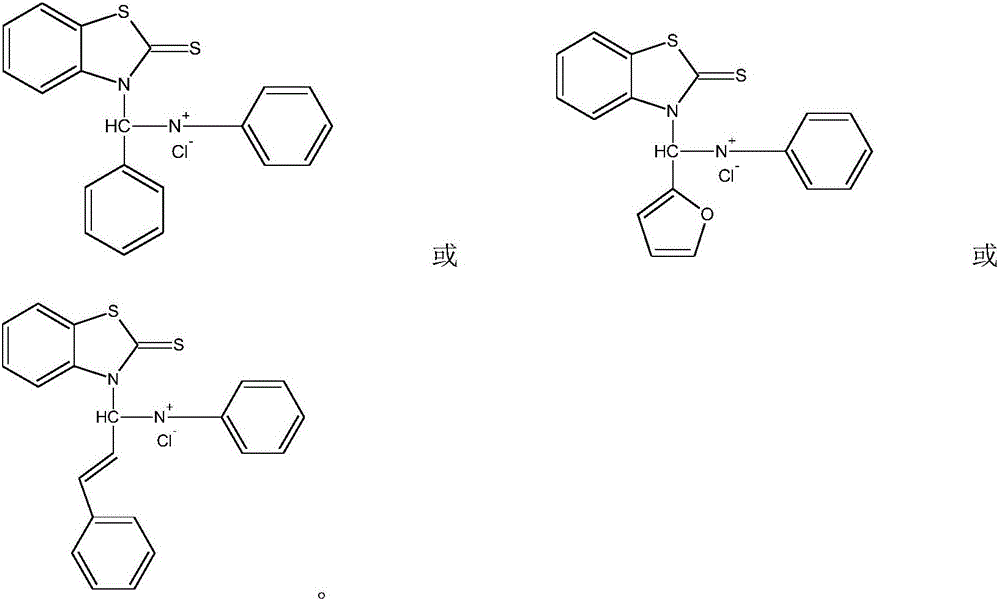

[0027] A, preparation of Mannich base quaternized derivatives, the steps include: the mol ratio is 1.0:1.5 2-mercaptobenzothiazole, benzaldehyde and ethanol are mixed and packed into a three-necked flask, the quality of the ethanol is 1.0 times the total mass of 2-mercaptobenzothiazole and benzaldehyde, stir, then slowly add aniline dropwise, the amount of aniline added is 0.5 times the mass of 2-mercaptobenzothiazole, after stirring evenly, adjust the pH of the system with hydrochloric acid to 2~3, react at 80~85°C for 7h to obtain the Mannich base compound; cool to 60°C, add benzyl chloride dropwise, the amount of benzyl chloride added is 0.5 times the mass of 2-mercaptobenzothiazole , and continue to react for 2 to 3 hours to obtain the quaternized ammonium derivative of Mannich base, its molecular formula is:

[0028] B. Mi...

Embodiment 2

[0035] This embodiment provides a kind of corrosion inhibitor for oilfield water flooding, and its preparation step comprises the following steps:

[0036] A, preparation of Mannich base quaternized derivatives, the steps include: mixing 2-mercaptobenzothiazole, furfural and ethanol with a molar ratio of 1.0:1.0 into a three-necked flask, the quality of the ethanol is 2 - 1.5 times the total mass of mercaptobenzothiazole and furfural, stir, and then slowly add aniline dropwise. The amount of aniline added is 0.4 times the mass of 2-mercaptobenzothiazole. After stirring evenly, use hydrochloric acid to adjust the pH of the system to 2~ 3. React at 80-90°C for 9 hours to obtain the Mannich base compound; cool to 60°C, add benzyl chloride dropwise, the amount of benzyl chloride added is 0.4 times the mass of 2-mercaptobenzothiazole, continue After reacting for 2-3 hours, the quaternized ammonium derivative of Mannich base is obtained, and its molecular formula is:

[0037] B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com