Chromium-free passivating agent for pylon and preparation method of chromium-free passivating agent for pylon

A chromium-free passivator and high-voltage line tower technology, which is applied in the coating process of metal materials, etc., can solve the problems of hexavalent chromium being harmful to health and polluting the environment, and achieve good weather resistance, simple preparation method, and strong corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

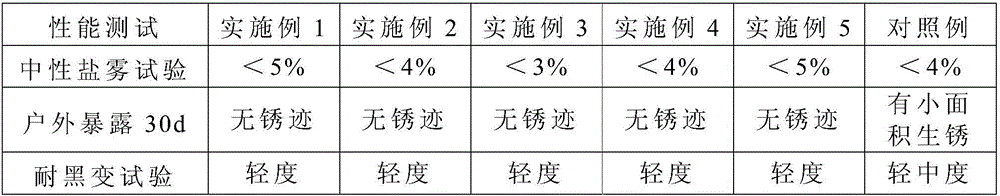

Examples

Embodiment 1

[0021] A chromium-free passivator for high-voltage line towers, including the following raw materials in parts by mass: 20 parts of phytic acid, 4 parts of sodium cinnamate, 3 parts of sodium gluconate, 6 parts of maleic acid resin, polytetrafluoroethylene concentrated 15 parts of dispersion liquid, 2 parts of fatty alcohol polyoxyethylene ether, 3 parts of sulfonated lignin, 13 parts of ethanol, and 15 parts of water, wherein the solid content of the polytetrafluoroethylene concentrated dispersion liquid is 58%.

[0022] The above-mentioned preparation method for the chromium-free passivating agent of high-pressure line tower, comprises the steps:

[0023] (1) First add sulfonated lignin to water, then add sodium cinnamate and sodium gluconate, and stir evenly to obtain mixture A;

[0024] (2) Add phytic acid, fatty alcohol polyoxyethylene ether and maleic acid resin to ethanol in sequence, and stir at 100r / min for 1-2h to obtain mixture B;

[0025] (3) Mix the mixture A and...

Embodiment 2

[0027] A chromium-free passivator for high-voltage line towers, including the following raw materials in parts by mass: 24 parts of phytic acid, 5 parts of sodium cinnamate, 5 parts of sodium gluconate, 7 parts of maleic acid resin, polytetrafluoroethylene concentrated 18 parts of dispersion liquid, 3 parts of fatty alcohol polyoxyethylene ether, 4 parts of sulfonated lignin, 16 parts of ethanol, and 19 parts of water, wherein the polytetrafluoroethylene concentrated dispersion has a solid content of 59%.

[0028] The above-mentioned preparation method for the chromium-free passivating agent of high-pressure line tower, comprises the steps:

[0029] (1) First add sulfonated lignin to water, then add sodium cinnamate and sodium gluconate, and stir evenly to obtain mixture A;

[0030] (2) Add phytic acid, fatty alcohol polyoxyethylene ether and maleic acid resin to ethanol in sequence, and stir at 105r / min for 1-2h to obtain mixture B;

[0031] (3) Mix the mixture A and the mix...

Embodiment 3

[0033] A chromium-free passivator for high-voltage line towers, including the following raw materials in parts by mass: 28 parts of phytic acid, 7 parts of sodium cinnamate, 6 parts of sodium gluconate, 9 parts of maleic acid resin, polytetrafluoroethylene concentrated 21 parts of dispersion liquid, 4 parts of fatty alcohol polyoxyethylene ether, 6 parts of sulfonated lignin, 20 parts of ethanol, and 23 parts of water, wherein the polytetrafluoroethylene concentrated dispersion has a solid content of 60%.

[0034] The above-mentioned preparation method for the chromium-free passivating agent of high-pressure line tower, comprises the steps:

[0035] (1) First add sulfonated lignin to water, then add sodium cinnamate and sodium gluconate, and stir evenly to obtain mixture A;

[0036] (2) Add phytic acid, fatty alcohol polyoxyethylene ether and maleic acid resin to ethanol in sequence, and stir at 110r / min for 1-2h to obtain mixture B;

[0037] (3) Mix the mixture A and the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com