Antibacterial nano-fiber non-woven material and preparation method

A technology of non-woven materials and nanofibers, which is applied in the field of non-woven materials, can solve the problems of non-woven materials with antibacterial properties that need to be improved, continuous production cannot be guaranteed, and polymer mixing is uneven, so as to achieve good hydrophilic properties and long-lasting antibacterial properties , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

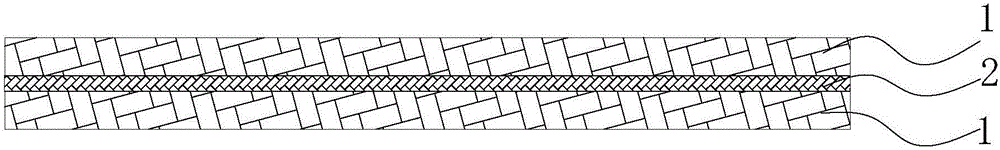

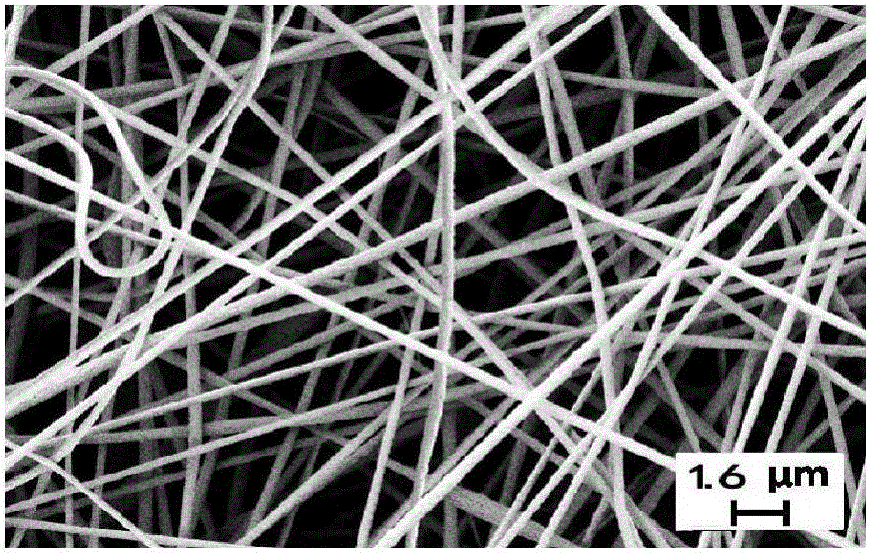

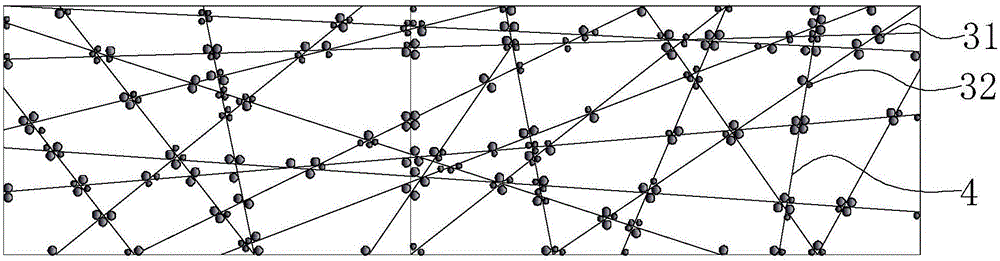

[0038] Add 0.2g of nano-silver antibacterial particles and 0.5g of nano-zinc oxide antibacterial particles to 20g polypropylene to make a spinning solution, apply high-voltage positive electricity on the spinning solution nozzle, and carry out electrospinning to the spinning solution. The extrusion rate of the liquid is 1-2ml / h, the spinning voltage is 60KV, and the receiving distance is 40cm to prepare nanofiber antibacterial materials; 20g of polypropylene is melted to prepare a spinning liquid, and a high voltage is applied to the spinning liquid nozzle. Electricity, electrospinning the spinning solution, the extrusion rate of the spinning solution is 1-2ml / h, the spinning voltage is 60KV, the receiving distance is 40cm, and the nanofiber material is prepared by diluting the hydrophilic agent with high-purity water. After the hydrophilic solvent is coated on the nanofiber material, the nanofiber hydrophilic material is prepared by drying; the prepared nanofiber antibacterial...

Embodiment 2

[0040] Add 0.1g of nano-silver antibacterial particles and 0.5g of nano-zinc oxide antibacterial particles to 10g polypropylene to make a spinning solution, apply high-voltage positive electricity on the spinning solution nozzle, and carry out electrostatic spinning to the spinning solution. The extrusion rate of the liquid is 1-2ml / h, the spinning voltage is 40KV, and the receiving distance is 20cm to prepare nanofiber antibacterial materials; 10g of polypropylene is melted to make spinning liquid, and a high voltage is applied to the spinning liquid nozzle. Electricity, electrospinning the spinning solution, the extrusion rate of the spinning solution is 1-2ml / h, the spinning voltage is 40KV, the receiving distance is 20cm, and the nanofiber material is prepared by diluting the hydrophilic agent with high-purity water. After the hydrophilic solvent is coated on the nanofiber material, the nanofiber hydrophilic material is prepared by drying; the prepared nanofiber antibacteri...

Embodiment 3

[0042] Add 0.15g of nano-silver antibacterial particles and 0.75g of nano-zinc oxide antibacterial particles to 15g polypropylene to make a spinning solution, apply high-voltage positive electricity on the spinning solution nozzle, and carry out electrospinning to the spinning solution. The extrusion rate of liquid is 0.5 ~ 1ml / h, the spinning voltage is 35KV, and the receiving distance is 25cm to prepare nanofiber antibacterial materials; 15g polypropylene is melted to make spinning liquid, and high pressure is applied to the spinning liquid nozzle Positive electricity, electrospinning the spinning solution, the extrusion rate of the spinning solution is 0.5 ~ 1ml / h, the spinning voltage is 35KV, the receiving distance is 25cm, and the nanofiber material is prepared, and the hydrophilic agent is diluted with high-purity water Prepare a hydrophilic solvent, apply the hydrophilic solvent to the nanofiber material, and dry to prepare the nanofiber hydrophilic material; cross-lay ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com