A special refractory rubber hose for controllable expansion oil field and its preparation method

A technology of fire-resistant rubber hose and fire-resistant glue, which is applied in the protection of hoses, pipes, and pipelines. It can solve the problems of obvious fire-resistant effect, difficulty in meeting harsh environments, and failure of rubber inner tubes, and achieve strong hot airflow and heat radiation. , Excellent controllable expansion performance, the effect of expanding the internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

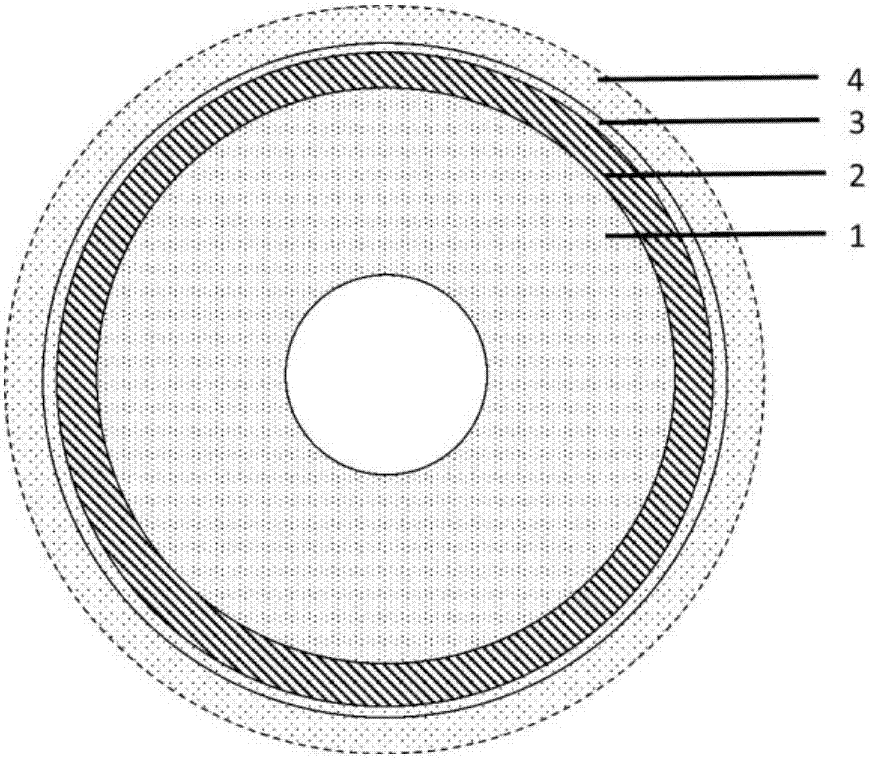

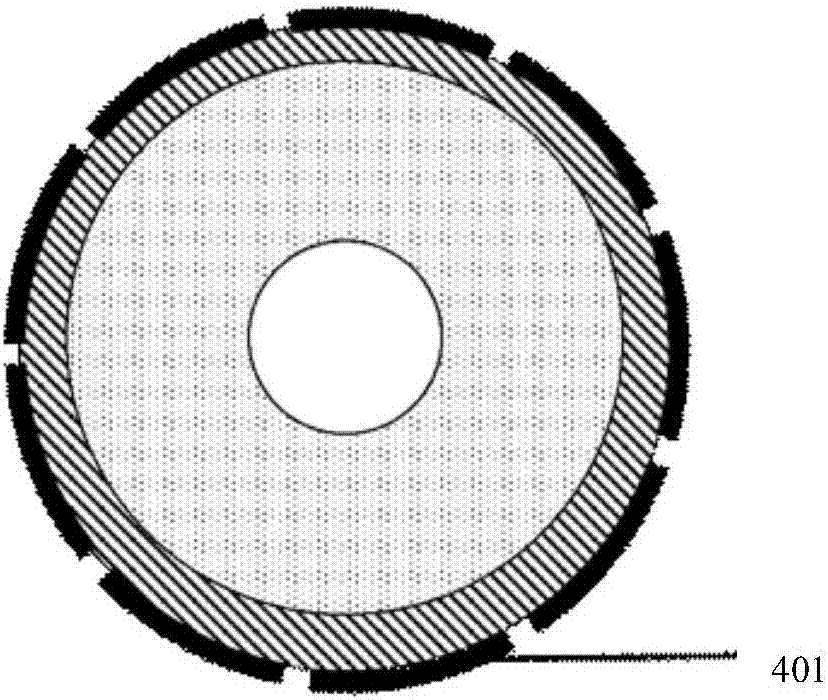

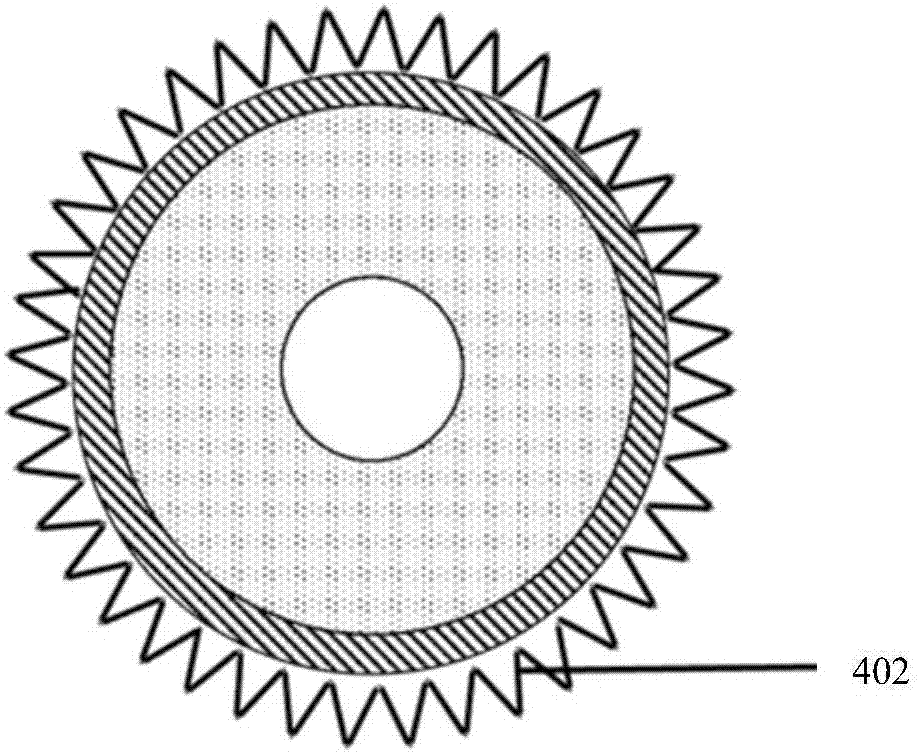

[0035] The invention provides a method for preparing a special fire-resistant rubber hose for controllable expansion oil fields, which combines Figure 1A-1D , the steps of the preparation method are as follows:

[0036] The first step is the preparation of the rubber inner tube 1 .

[0037] The rubber inner tube is prepared by an open mill, an extruder and a winding machine. The rubber inner tube is divided into an inner rubber layer, a reinforcing layer and an outer rubber layer, wherein the inner rubber layer is a rubber with oil resistance function, which can be selected from nitrile rubber (temperature resistance less than 125°C), acrylic rubber (temperature resistance 150-200°C), fluororubber (temperature resistance 200-250°C) and other rubbers; the reinforcement layer is braided fabric, including carbon fiber, glass Fiber, basalt fiber, aramid fiber, metal wire and other fibers or wires prepared by one or more of the braids; the outer rubber layer is a rubber protectiv...

Embodiment 1

[0071] The method provided by the present invention is used to prepare the fire-resistant rubber tubing specially used for controllable expansion oil fields with a high-efficiency thermal protection structure, as follows:

[0072] The first step is to prepare the rubber inner tube. Select the rubber material of the inner rubber layer and the outer rubber layer, knead on the open mill and add relevant additives, and set aside. To produce rubber tubing with an inner diameter of 10±0.5mm and a wall thickness of 10.5±0.5mm (the thickness of the fluororubber inner layer is 7mm, the thickness of the reinforcement layer is 0.5mm, and the thickness of the epichlorohydrin rubber outer layer is 3mm), the method steps are as follows:

[0073] (1) The fluororubber inner rubber layer is extruded through the extruder, and the extrusion temperature is 70°C, 60°C, 60°C, 60°C from the machine head to the screw;

[0074] (2) Use aramid fiber to weave the reinforcement layer, wrap it on the sur...

Embodiment 2

[0084] Adopt the method provided by the invention to prepare the rubber oil pipe with efficient thermal protection structure, specifically as follows:

[0085] The first step is to prepare the rubber inner tube. Mix the rubber of the inner rubber layer and the outer rubber layer on an open mill and add relevant additives for later use. To produce rubber tubing with an inner diameter of 10.0±0.5mm and a wall thickness of 10.5±0.5mm (the thickness of the fluorine rubber inner rubber layer is 7.0mm, the thickness of the reinforcing layer is 0.5mm, and the thickness of the epichlorohydrin rubber outer rubber layer is 3mm), the method steps are as follows :

[0086] (1) The fluorine rubber inner rubber layer is extruded through the extruder, and the extrusion temperature is 80°C, 70°C, 70°C, 70°C from the machine head to the screw;

[0087] (2) Use aramid fiber to weave the reinforcement layer, wrap it on the surface of the inner rubber layer, and start to extrude the outer rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com