A system and method for self-powered drying and pyrolysis of organic matter, full-component recycling

A process method and technology of organic matter, applied in the field of full-component resource recycling system, organic matter self-energy drying and pyrolysis, can solve the problems of low heating efficiency, reduced energy efficiency, inability to separate drying and pyrolysis processes, etc., to achieve energy utilization High efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

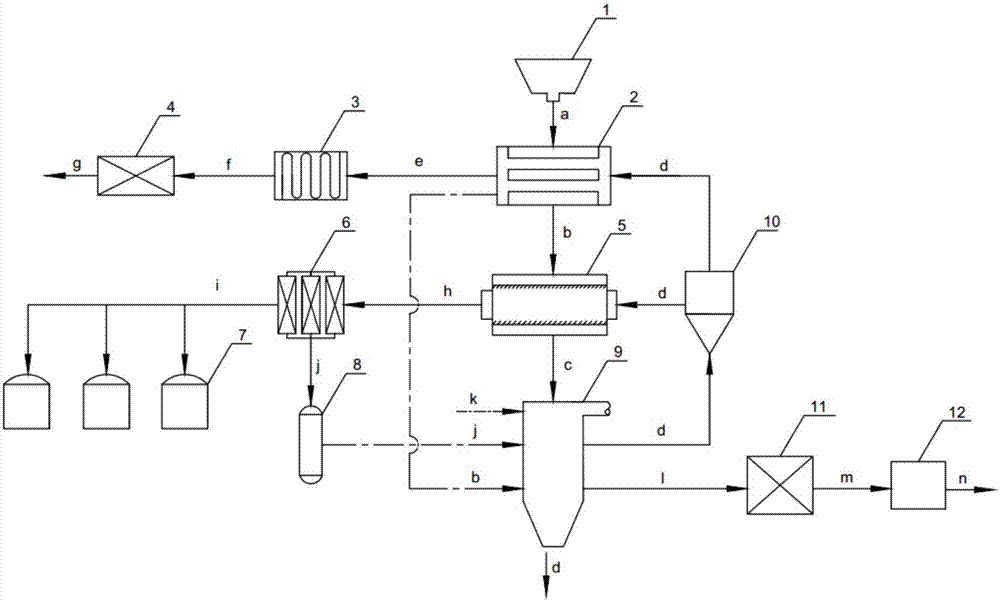

[0025] The present invention discloses a self-powered drying and pyrolysis of organic matter, and a full-component recycling system, including a feed bin 1, a drying device 2, a condenser A3, a water treatment device 4, a pyrolysis furnace 5, A condenser B6, an oil storage tank group 7, a gas storage tank 8, a combustion furnace 9, a slag separator 10, a waste heat recovery device 11, and a flue gas purification device 12.

[0026] Feed bin 1 is used to receive and transport organic matter a. The organic matter a can be coal, biomass, garbage, waste tires, waste organic matter, organic sludge and the like.

[0027] The drying device 2 is connected to the feed bin 1 and is used to receive and heat the organic matter a, and separate it into water vapor e and dry organic matter b.

[0028] The condenser A3 is connected to the drying device 2 for receiving and cooling the water vapor e into condensed water f.

[0029] The water treatment device 4 is connected to the condenser A3...

Embodiment 2

[0046] The invention discloses a self-powered drying and pyrolysis of organic matter, and a process method for resource utilization of all components, which comprises the following steps:

[0047] Conveying the organic matter a through the feed bin 1 into the drying device 2 for heating and drying;

[0048] The water vapor e evaporated in the drying device 2 enters the condenser A3 to condense to generate condensed water f;

[0049] The condensed water f enters the water treatment device 4, and after purification treatment, the purified water g is obtained and then discharged or utilized;

[0050] The obtained dry organic matter b enters the pyrolysis furnace 5, and in the pyrolysis furnace 5, it is further cracked into pyrolysis volatile matter h and semi-coke c

[0051] The pyrolysis volatile matter h enters the condenser B6, and is condensed into pyrolysis oil i and non-condensable combustible gas j through the condenser B6;

[0052] Condenser B6 is divided into 3-4 conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com