A confocal and confocal alignment micro-assembly system and calibration method

A micro-assembly and co-imaging technology, which is applied in the field of micro-assembly and microscopic visual inspection, can solve the problems that the precise positioning requirements cannot be met in occasions, and the accuracy of part alignment detection is difficult to reach the sub-micron level, etc. The method is simple and easy to achieve , Improving the assembly accuracy and improving the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

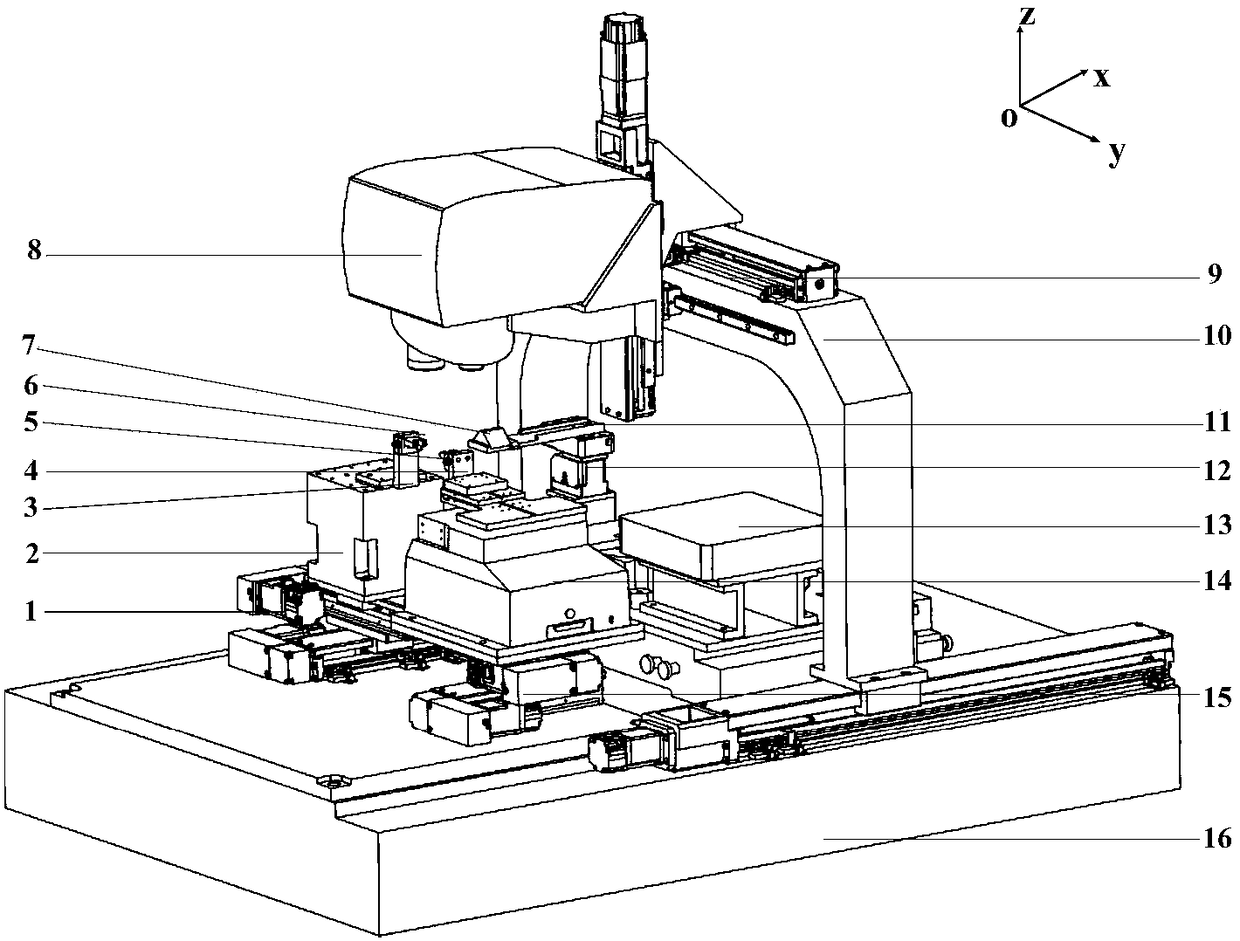

[0052] figure 1 It is a three-dimensional structure diagram of a confocal co-image alignment micro-assembly system of the present invention, and oxyz is the coordinate system of the system. Including target part two-dimensional displacement stage 1, target part lift table 2, target part holder 3, base part holder 4, base part 5, target part 6, trapezoidal prism 7, laser confocal microscope 8, grating ruler 9 , Gantry mechanism 10 , prism clamping mechanism 11 , prism posture adjustment mechanism 12 , detection table 13 , six-degree-of-freedom PI parallel micro-motion platform 14 , base part two-dimensional displacement table 15 , marble table 16 . The target part holder 3 is used to hold the target part 6, and below it is the target stage composed of the target part two-dimensional displacement stage 1 and the target part lifting table 2, which can realize the target part 6 along the x, y and z three directions. Linear displacement in one direction. The base part holder 4 is...

Embodiment 2

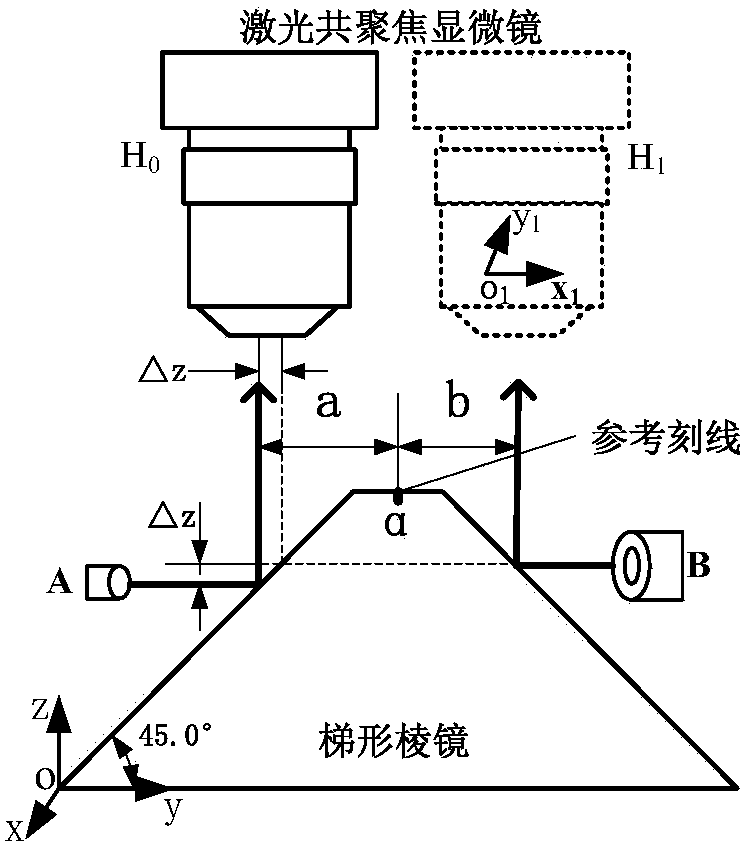

[0055] figure 2 It is the assembly principle diagram of a confocal confocal alignment micro-assembly system in the present invention and this embodiment; figure 2 As can be seen from the above, oxyz is the coordinate system of the system, and o1x1y1 is the image coordinate system of the system;

[0056] Before the system is assembled, the target part A and the base part B need to be installed on the target part holder and the base part holder respectively. After adjustment, there is a positional deviation between A and B in the x and z directions; the system assembly steps, details as follows:

[0057] First, move the laser confocal microscope to the H0 position to obtain the end face image of part A, so that the center line of the end face image coincides with the y1 axis of the confocal microscope image coordinate system;

[0058] Then, move the laser confocal microscope to the right above the reference line α, adjust the lens to obtain a clear image of the reference lin...

Embodiment 3

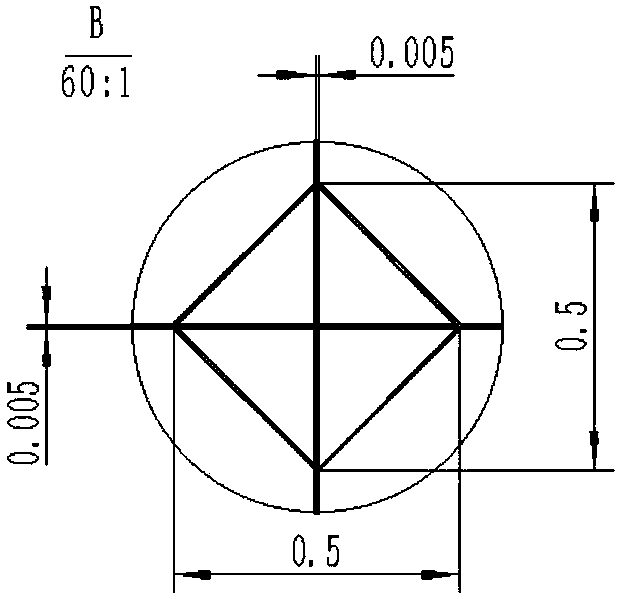

[0062] In this embodiment, a special trapezoidal prism is used. The two inclined surfaces of the trapezoidal prism are coated with a high-reflectivity aluminum film and a magnesium fluoride protective film. The reflectivity of the aluminum film for laser light with a wavelength of 400-700 nm is above 90%; the prism material is BK7; the surface accuracy is 1 / 4λ; the partial enlarged image of the upper surface pattern of the trapezoidal prism is shown in the figure image 3 As shown in the figure, it can be seen that there are reference cross scribe lines and square pattern scribe lines on the upper surface of the trapezoidal prism, the diagonal length of the square pattern is 0.5mm, and the line width of the reference cross scribe line and the square pattern are both 5 μm;

[0063] Figure 4 This is a flow chart of the present invention and a method for confocal alignment micro-assembly calibration in this embodiment. Depend on Figure 4 It can be seen from the above that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com