Non-aqueous electrolyte and lithium-ion battery employing same

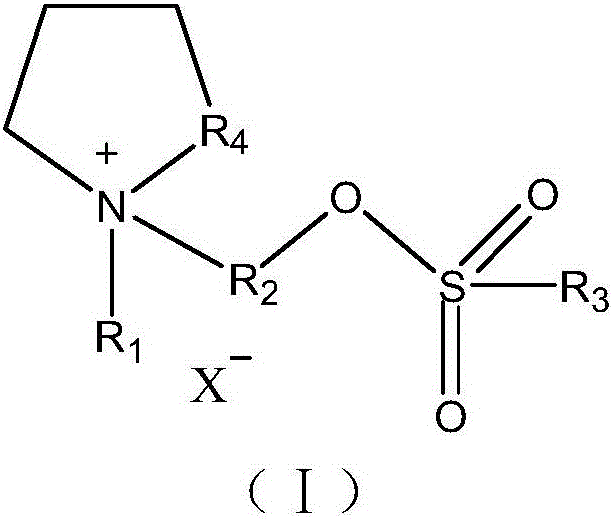

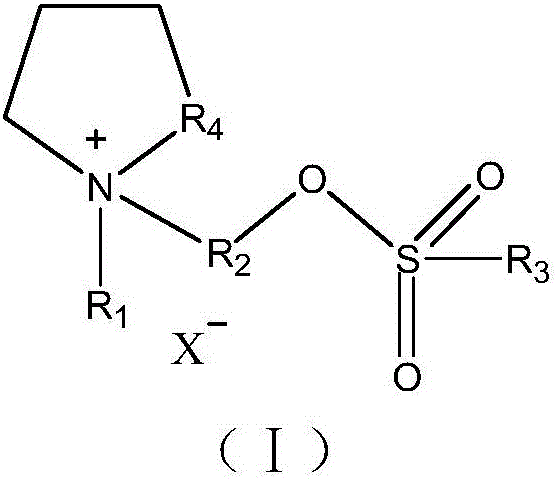

A non-aqueous electrolyte and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve the problems of electrolyte consumption, reduced battery capacity, and poor high-temperature performance, and achieve the effects of improved wettability, small impedance, uniform and dense impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0073] [Reference Example 1] Synthesis of Compound A

[0074]

[0075] First step response:

[0076]

[0077] Second step reaction:

[0078]

[0079] The third step reaction:

[0080]

[0081] Operation steps: add 200ml methylene chloride as a solvent in a sealed flask with stirring, then add methanesulfonyl chloride (19.4g, 169.4mmol) as a reaction substrate, 15g bromoethanol (121mmol) is dissolved in 18.3g triethylamine was slowly added to the above solution. After the addition was complete, the stirring reaction was continued for 3 hours, and the reaction ended. The reactant was washed with saturated brine, the upper organic phase was separated, and the solvent was removed by heating to obtain the initial product, which was purified by silica gel column separation (eluting solvent: cyclohexane / ethyl acetate=3 / 2) to obtain 22.6 g of a colorless oil , as the product compound IL-1-1 of the next reaction.

[0082] 13g (64.0mmol) of the above compound was dissol...

reference example 2

[0088] [Reference Example 2] Synthesis of Compound B

[0089]

[0090] First step response:

[0091]

[0092] Second step reaction:

[0093]

[0094] The third step reaction:

[0095]

[0096] Operation steps: add 200ml methylene chloride as solvent in a sealed flask with stirring, then add methanesulfonyl chloride (19.4g, 169.4mmol) as the reaction substrate, 15g (121mmol) bromoethanol is dissolved in 18.3g triethylamine was slowly added to the above solution. After the addition was complete, the stirring reaction was continued for 3 hours, and the reaction ended. The reactant was washed with saturated brine, the upper organic phase was separated, and the solvent was removed by heating to obtain the initial product, which was purified by silica gel column separation (elution solvent was cyclohexane / ethyl acetate=3 / 2) to obtain 22.6 g of a colorless oil , as the product compound IL-2-1 of the next reaction.

[0097] 22g (108.4mmol) of the above compound was di...

Embodiment 1

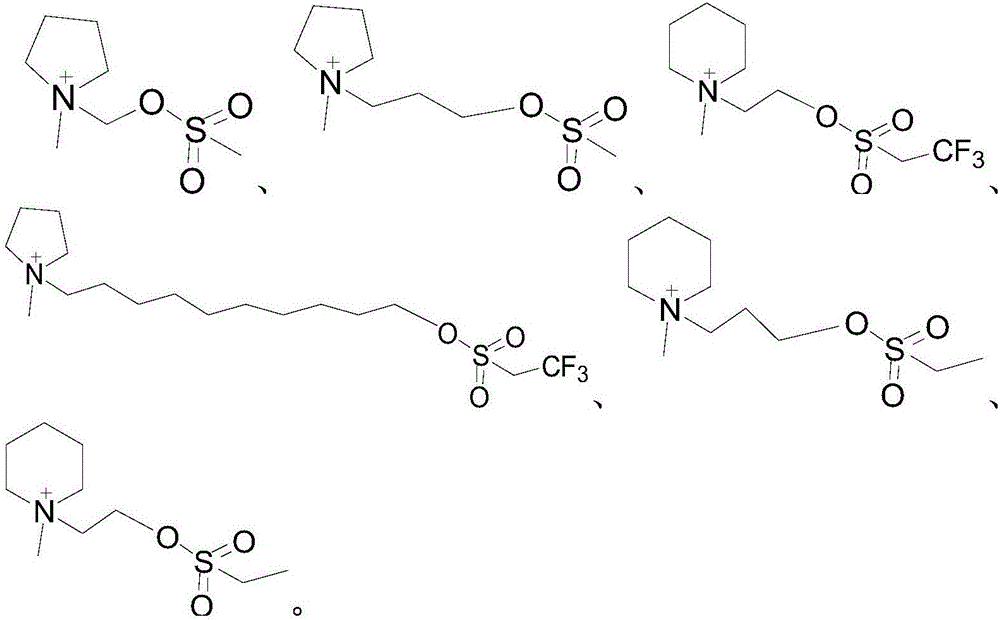

[0114] Through the M6S process, the positive electrode LiCoO is manufactured 2 , Negative electrode graphite soft pack cell, dried at 85°C until the water content is below 200ppm, inject the prepared electrolyte into the cell. The specific structure of the additive compound in the electrolyte is shown in Table 1, and the composition of the electrolyte is shown in Table 2.

[0115] Table 1:

[0116]

[0117] Table 2:

[0118]

[0119]

[0120] The performance of the lithium-ion battery electrolyte additive of the present application and the lithium-ion battery using the additive is described below through experimental data.

[0121] Test 1: capacity retention rate test, the purpose is to test the improvement of the low-temperature cycle performance of the electrolyte.

[0122] After the completion of the preparation, the 0.5C charge-discharge current of each example and the comparative example was repeatedly charged and discharged between 3.0V and 4.35V at 25°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com