Ginseng tablet capable of strengthening spleen and preparation method thereof

A technology of ginseng invigorating spleen tablets and ginseng, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of affecting drug absorption, unscientific, and disintegration time of ginseng invigorating spleen tablets long wait question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

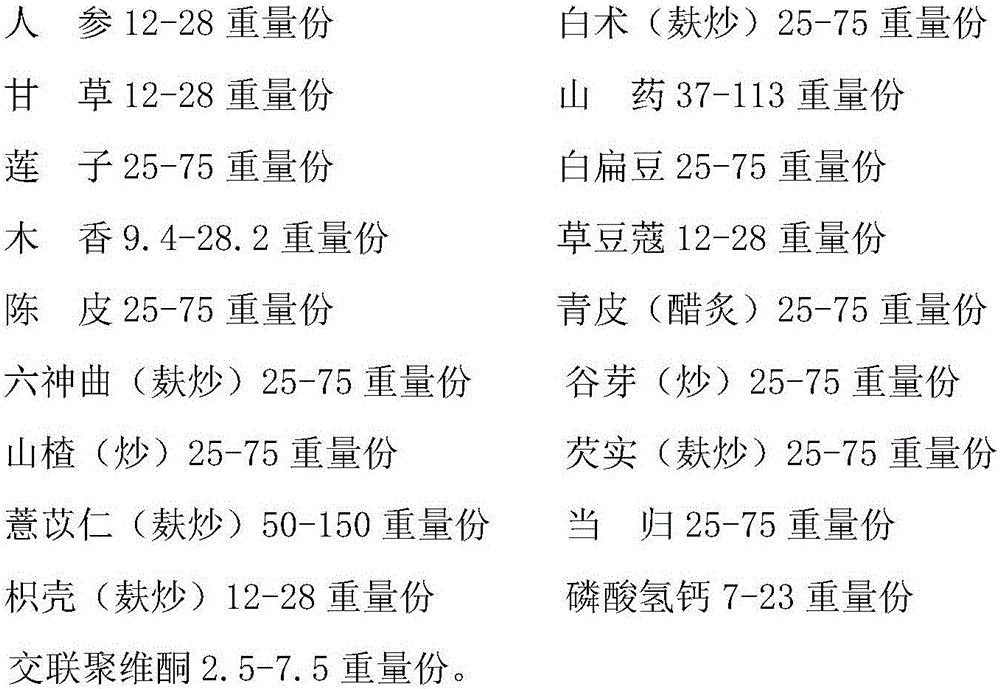

[0110]

[0111]

[0112] The preparation method is:

[0113] Wash ginseng, Atractylodes macrocephala, licorice, lotus seeds, white lentils, Gorgon fruit and angelica respectively, soak them in 3 times the amount of water for 10 hours, remove them, and dry the water, keep the surface of Chinese medicinal materials dry, and freeze them at -20°C for 2 hours Carry out ultrafine pulverization in the environment of -6 DEG C afterward to obtain superfine powder; After superfine pulverization, 90%-95% of the micropowder particle size is 4-6 micron; Soak yam with 8 times the amount of water for 30 minutes, Add 12g of compound enzyme, the compound enzyme is 3:1 α-amylase and protein phosphatase, first carry out enzymolysis at 40°C for 30 minutes, then decoct, decoct for the first time for 3 hours, filter to obtain the filtrate , decoct the dregs with 6 times the amount of water for 2 hours, filter to obtain the filtrate, combine the two filtrates, filter, concentrate the filtrate ...

Embodiment 2

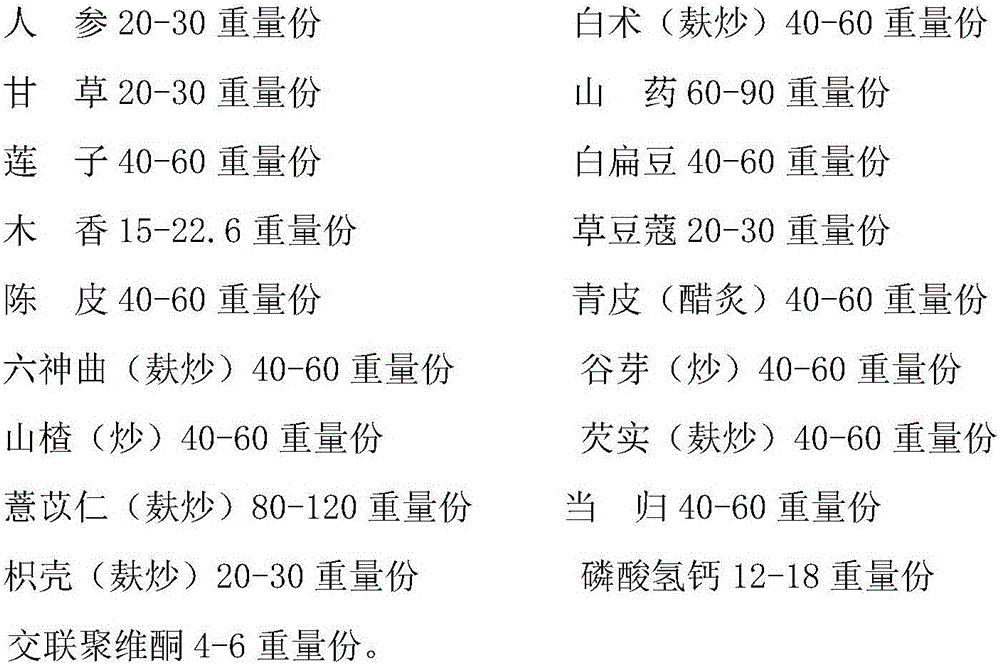

[0115]

[0116]

[0117] Wash ginseng, Atractylodes macrocephala, licorice, lotus seeds, white lentils, Gorgon fruit and angelica respectively, soak them in 3 times the amount of water for 10 hours, remove them, and dry the water, keep the surface of Chinese medicinal materials dry, and freeze them at -20°C for 2 hours Carry out ultrafine pulverization in the environment of -6 DEG C afterward to obtain superfine powder; After superfine pulverization, 90%-95% of the micropowder particle size is 4-6 micron; Soak yam with 8 times the amount of water for 30 minutes, Add 12g of compound enzyme, the compound enzyme is 3:1 α-amylase and protein phosphatase, first carry out enzymolysis at 40°C for 30 minutes, then decoct, decoct for 3 hours for the first time, filter to obtain the filtrate , decoct the dregs with 6 times the amount of water for 2 hours, filter to obtain the filtrate, combine the two filtrates, filter, concentrate the filtrate to 80°C, measure the relative density...

Embodiment 3

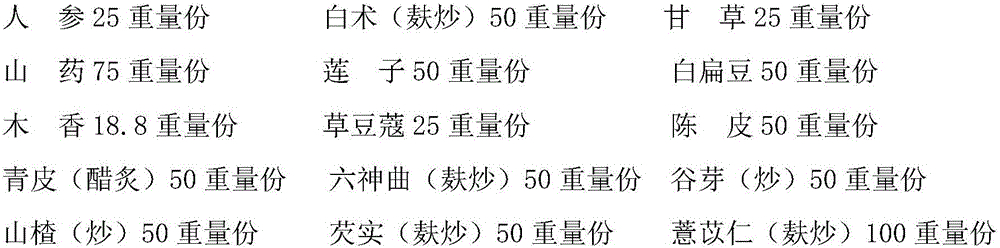

[0119]

[0120]

[0121] Wash ginseng, Atractylodes macrocephala, licorice, lotus seeds, white lentils, Gorgon fruit and angelica respectively, soak them in 3 times the amount of water for 10 hours, remove them, and dry the water, keep the surface of Chinese medicinal materials dry, and freeze them at -20°C for 2 hours Carry out ultrafine pulverization in the environment of -6 DEG C afterward to obtain superfine powder; After superfine pulverization, 90%-95% of the micropowder particle size is 4-6 micron; Soak yam with 8 times the amount of water for 30 minutes, Add 12g of compound enzyme, the compound enzyme is 3:1 α-amylase and protein phosphatase, first carry out enzymolysis at 40°C for 30 minutes, then decoct, decoct for the first time for 3 hours, filter to obtain the filtrate , decoct the dregs with 6 times the amount of water for 2 hours, filter to obtain the filtrate, combine the two filtrates, filter, concentrate the filtrate to 80°C, measure the relative density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com