Method for directly synthesizing Cu-doped zeolite CHA by taking cheap Si and Al as raw materials

A technology of silicon-alumina and raw materials, which is applied in the field of directly synthesizing Cu-doped zeolite CHA from cheap silicon-alumina raw materials, can solve the problems of high price of amantadine, long synthesis cycle, and limited application, so as to alleviate secondary environmental problems and avoid Ion exchange step, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

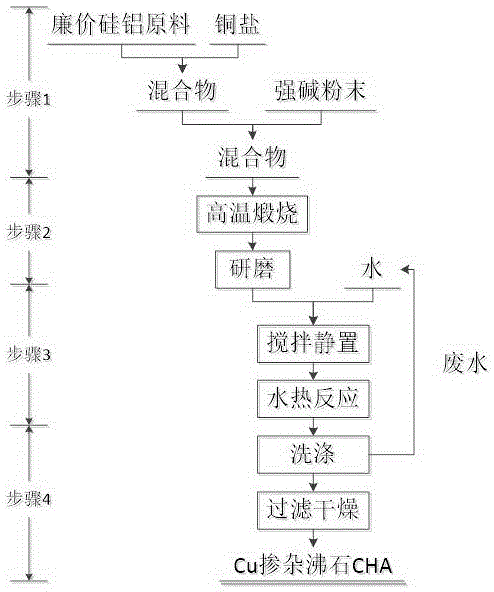

Method used

Image

Examples

Embodiment 1

[0021] Weigh 1.20 g of silica powder and 3.75 g of alumina powder (silicon to aluminum molar ratio 2:1), mix with 10.87 g of copper nitrate powder; add 15.82 g of potassium hydroxide powder and mix evenly. The mixture was transferred to a high-temperature furnace, calcined at 650 °C for 1 h in an air atmosphere, and ground into powder after cooling to room temperature. Take an appropriate amount of the above powder, dissolve it in ultrapure water at a solid-to-liquid mass ratio of 4:1, stir for 30 minutes, let it stand for 60 minutes, transfer it to a high-pressure reactor and seal it, and conduct a hydrothermal reaction in a constant temperature drying oven at 95°C for 4 sky. The hydrothermal reaction product was washed 5 times with ultrapure water, filtered, and dried at 100 °C for 12 h to obtain the product.

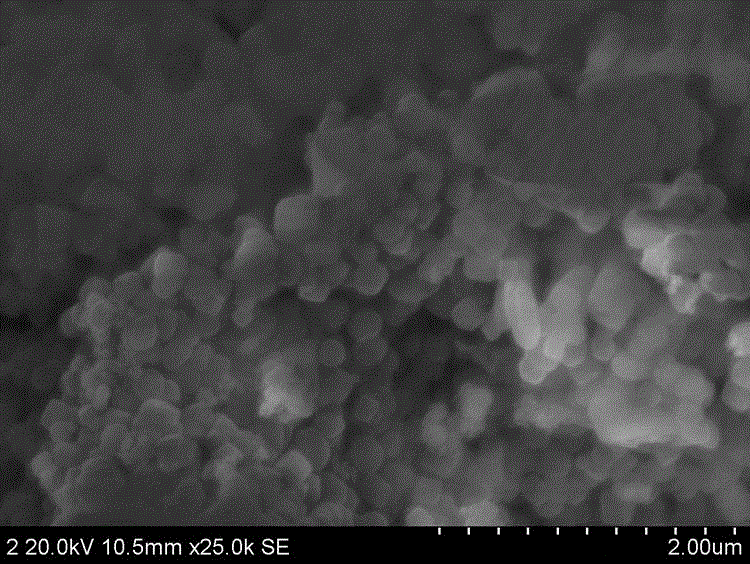

[0022] figure 2 SEM image of Cu-doped zeolite CHA. It can be seen from the figure that the crystal size of the product is uniform, uniformly dispersed, and has a ...

Embodiment 2

[0024] Weigh 1.20 g of quartz sand, crush and sieve with a pulverizer, mix 200-mesh powder with 4.0 g of alumina powder and 12.0 g of copper chloride powder, and then add 16.0 g of pulverized potassium hydroxide powder. The mixture was calcined at 650°C for 2 h to fully react the molten potassium hydroxide with other raw materials, and then ground after cooling. Take an appropriate amount of the above powder, dissolve it in ultrapure water at a solid-to-liquid mass ratio of 5:1, stir for 50 min, let it stand for 60 min, transfer it to a high-pressure reactor and seal it, and conduct a hydrothermal reaction at 100 °C for 3 days. The hydrothermal reaction product was repeatedly washed, filtered and dried at 100°C for 12 h to obtain a powder product.

Embodiment 3

[0026] Weigh 5.0 g of fly ash (silicon-aluminum molar ratio 1:1), mix with 10.0 g of copper nitrate powder; then add 8.0 g of sodium hydroxide powder and mix evenly. The mixture was transferred to a high-temperature furnace, calcined at 600 °C for 1 h in an air atmosphere, and ground into powder after cooling to room temperature. Take an appropriate amount of the above powder, dissolve it in tap water at a solid-to-liquid mass ratio of 6:1, stir for 30 min, let it stand for 90 min, transfer it to a high-pressure reactor and seal it, and conduct a hydrothermal reaction in a constant temperature drying oven at 95°C for 6 days. The hydrothermal reaction product was washed repeatedly, filtered and dried at 100 °C for 12 h to obtain the Cu-doped zeolite CHA product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com