Domestic sewage treatment process

A domestic sewage and treatment process technology, applied in the field of water treatment, can solve the problems of heavy maintenance workload, low efficiency, large wetland area, etc., and achieve the effect of improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further clarified below in conjunction with the drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

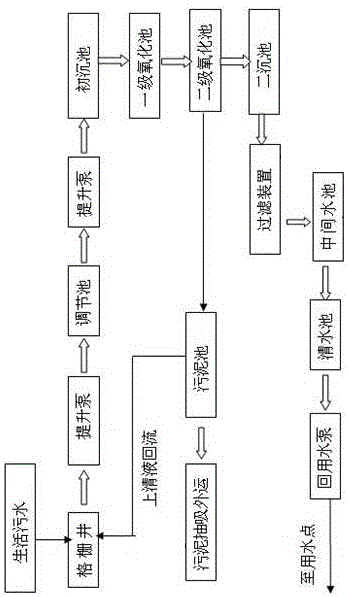

[0023] A domestic sewage treatment process includes the following steps:

[0024] (1) Domestic sewage is preliminarily filtered through the grid well, and then sent from the lifting pump to the regulating tank. After the volume of sewage is adjusted by the regulating tank and the sewage quality is balanced, it is sent from the lifting pump to the primary sedimentation tank;

[0025] (2) The sediment and other solids in the sewage in the primary sedimentation tank sink to the bottom of the tank, and the upper sewage enters the primary oxidation tank;

[0026] (3) The primary oxidation tank is divided into adjustment zone, oxidation zone and neutralization zone by partitions. The pH of acid solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com