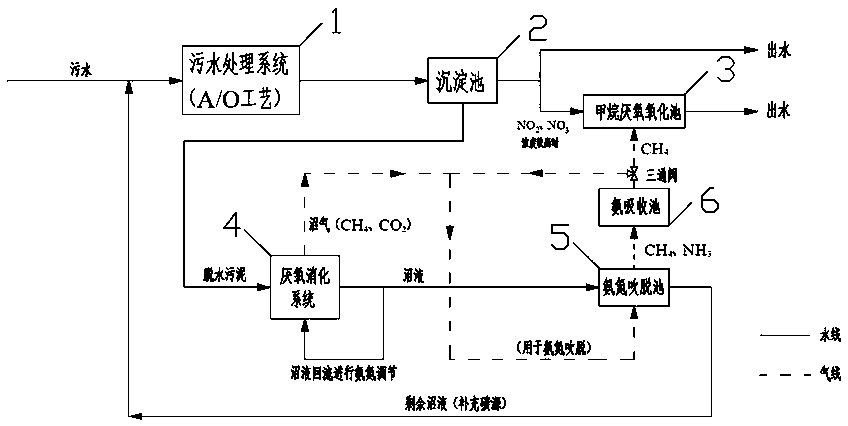

A sewage treatment process that efficiently utilizes carbon sources in sludge

A technology of sewage treatment and sewage treatment system, which is applied in the field of sewage treatment technology that efficiently utilizes carbon sources in sludge, can solve problems such as increasing sewage treatment costs, achieve the goals of improving comprehensive utilization, system stability, and reducing nitrogen content in effluent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The effluent from the primary sedimentation tank of a sewage treatment plant in Shanghai is used as the influent, and the influent volume is A 2 / O bioreactor, HRT is 8h, SRT is 3d, for sewage treatment, the effluent enters the sedimentation tank for mud-water separation.

[0027] (1) The denitrification sludge that has been operated for a long time with acetic acid as the substrate is used as the inoculation sludge, and the methane anaerobic oxidation tank is started under anoxic conditions. During the operation, methane gas is continuously introduced into the reactor. After 6 months of running, NO in the reactor 3 - -N removal rate up to 295 mgL -1 d -1 , and maintained a good stability; the remaining ammonia nitrogen in the effluent of the sedimentation tank enters the methane anaerobic oxidation tank in stable operation, and uses the methane generated by the anaerobic digestion of the sludge for deep denitrification;

[0028] (2) Add 1:1 (VS:VS) inocu...

Embodiment 2

[0033] (1) Take the effluent from the primary sedimentation tank of a sewage treatment plant in Shanghai as the influent, and the influent volume is A 2 / O bioreactor, HRT is 8 hours, SRT is 3 days, for sewage treatment, the effluent enters the sedimentation tank for mud-water separation;

[0034] (2) The denitrification sludge that has been operated for a long time with acetic acid as the substrate is used as the inoculation sludge, and the methane anaerobic oxidation tank is started under anoxic conditions, and methane gas is continuously introduced into the reactor during operation. running, NO in the reactor 3 - -N removal rate up to 289 mgL -1 d -1 , and maintained a good stability; the remaining ammonia nitrogen in the effluent of the sedimentation tank enters the methane anaerobic oxidation tank in stable operation, and uses the methane generated by the anaerobic digestion of the sludge for deep denitrification;

[0035] (3) Add 1:1 (VS:VS) inoculum sludge and raw s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com