Novel PVC (polyvinyl chloride) profile and preparation method thereof

A profile and a new type of technology, applied in the field of decorative materials, can solve the problems of poor apparent quality and poor gloss of PVC profiles, and achieve the effects of excellent thermal insulation performance, smooth surface and improved tensile impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

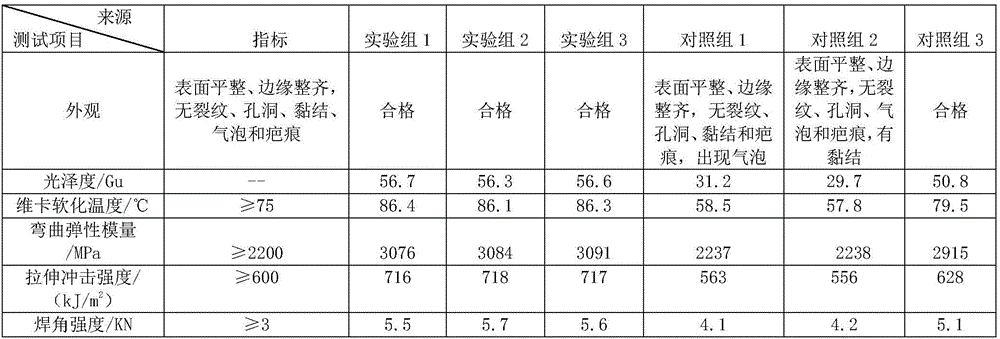

Examples

Embodiment 1

[0026] A new type of PVC profile, which consists of: 65kg of PVC waste, 12kg of sawdust, 13kg of 600-mesh light calcium carbonate, 0.72kg of rutile titanium dioxide, 2.5kg of EVA impact modifier, 1.8kg of MBS impact modifier, 0.84 kg of tin maleate, 0.48 kg of epoxy grease, 0.18 kg of ethyl bis stearamide, 0.45 kg of ethylene bis stearic acid and 2.4 kg of siloxane coupling agent.

[0027] The preparation method of described novel PVC profile is:

[0028] A. Grind PVC waste into powder and put it in a mixer, then add sawdust and light calcium carbonate to the mixer and stir for 8 minutes at a temperature of 136°C;

[0029] B. Mix maleic acid tin salt, epoxy grease, ethyl bis stearamide, ethylene bis stearic acyl, EVA impact modifier, MBS impact modifier, siloxane coupling agent and rutile Formed titanium dioxide was sequentially added to the mixture obtained in step A, stirred at 83°C for 9 minutes; then cooled to room temperature, extruded after discharge, and the new PVC pr...

Embodiment 2

[0031] A new type of PVC profile, which consists of: 55kg of PVC waste, 12kg of sawdust, 13kg of 600-mesh light calcium carbonate, 0.84kg of rutile titanium dioxide, 3.2kg of EVA impact modifier, 1.8kg of MBS impact modifier, Fatty acid tin salt 0.96kg, epoxidized soybean oil 0.51kg, ethyl bis stearamide 0.22 kg, ethylene bis stearic acid acyl 0.55 kg and siloxane coupling agent 1.5 kg.

[0032] The preparation method of described novel PVC profile is:

[0033] A. Put the PVC waste into powder and put it in the mixer, then add sawdust and light calcium carbonate into the mixer and stir at 129°C for 13 minutes;

[0034] B. Combine fatty acid tin salt, epoxidized soybean oil, ethyl bis stearamide, ethylene bis stearic acyl, EVA impact modifier, MBS impact modifier, siloxane coupling agent and rutile Titanium dioxide was sequentially added to the mixture obtained in step A, stirred at 78° C. for 6 minutes; then cooled to room temperature, discharged and then extruded to obtain t...

Embodiment 3

[0036] A new type of PVC profile, which consists of: 60kg of PVC waste, 13.6kg of sawdust, 14kg of 500-mesh light calcium carbonate, 0.75kg of rutile titanium dioxide, 2.8kg of EVA impact modifier, and 2.1kg of MBS impact modifier , fatty acid tin salt 0.88kg, epoxy grease 0.49kg, ethyl distearyl 0.2kg, ethylene distearyl 0.5kg and siloxane coupling agent 1.8kg.

[0037] The preparation method of described novel PVC profile is:

[0038] A. Grind PVC waste into powder and put it in a mixer, then add sawdust and light calcium carbonate into the mixer and stir for 11 minutes at a temperature of 134°C;

[0039] B. Combine fatty acid tin salt, epoxy resin, ethyl bis stearamide, ethylene bis stearic acid acyl, EVA impact modifier, MBS impact modifier, siloxane coupling agent and rutile titanium White powder was added to the mixture obtained in step A in turn, stirred at 81°C for 8 minutes; then cooled to room temperature, extruded after discharge, and the new PVC profile was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com