Method for reducing urea in fermented grains of Luzhou-flavor liquor

A technology of fermented grains and liquor, which is applied in the field of microbial production and utilization, and can solve problems such as increasing the chance of carcinogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Liquor brewing process

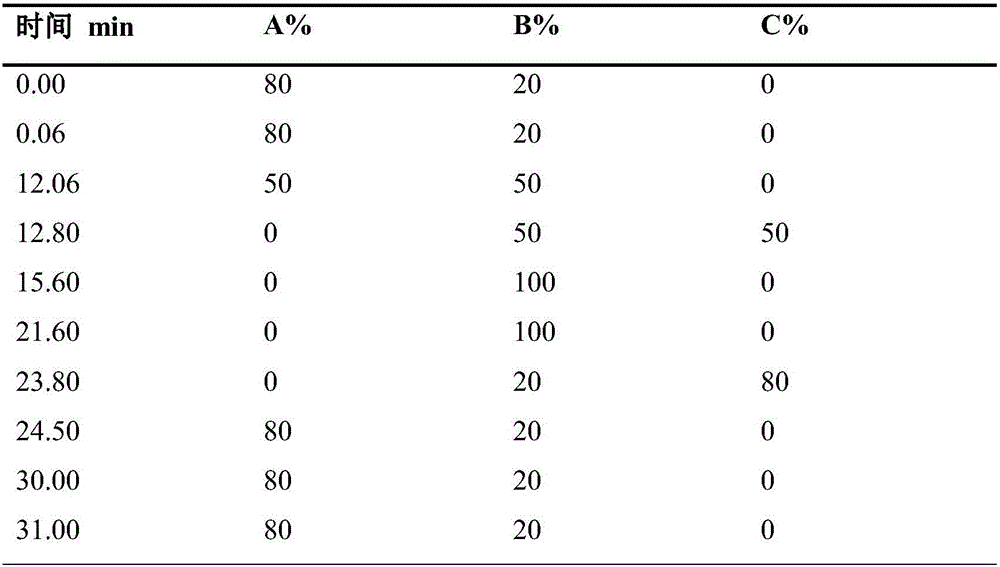

[0029] After the five grains (rice, glutinous rice, corn, wheat, sorghum, the ratio is 24:18:10:11:17) are added with hydrating ingredients, the fermented grains from the cellar are added, mixed well, put into a retort to distill the wine, and spread out to dry. Add water (90°C), wait until the temperature drops to normal temperature (18-19°C), stir in Daqu, and at the same time add Staphylococcus saprophyticus, Lactobacillus reuteri or crude enzyme solution or commercial urease (commercial urease purchased from Bioengineering (Shanghai) ) Co., Ltd., No. A003885, manufacturer Worthington BiotecnicalCorperation), the inoculum of Staphylococcus saprophyticus is 10 7 ~10 8 CFU / g, Lactobacillus reuteri inoculation amount is 10 7 ~10 8 CFU / g, the amount of enzyme solution for Staphylococcus saprophyticus is 43.9-45.6U / g, the amount of enzyme solution for Lactobacillus reuteri is 0.19U / g, and the amount of commercial urease is 0.19U / g....

Embodiment 2

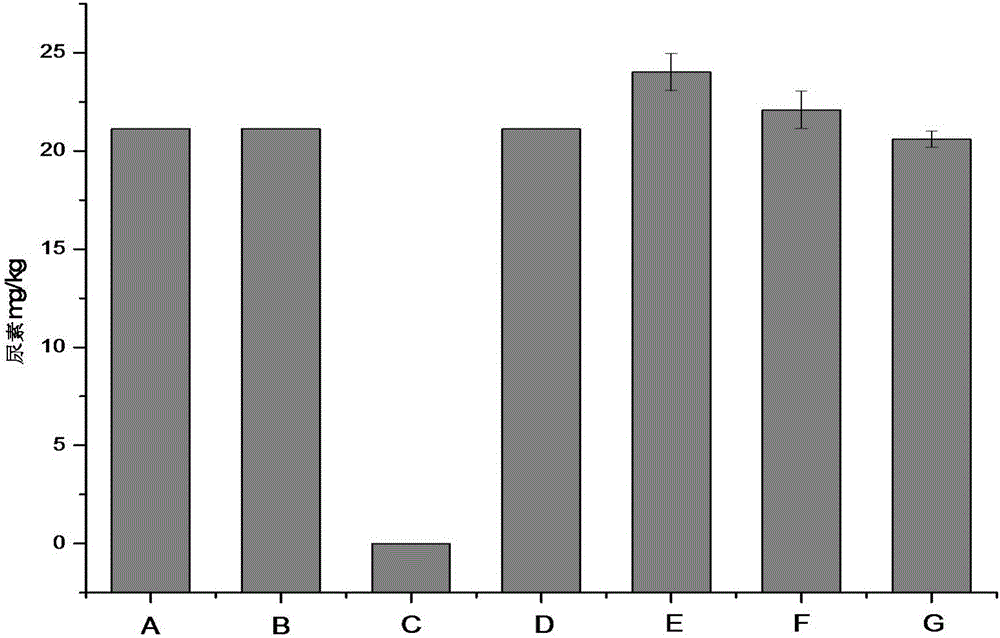

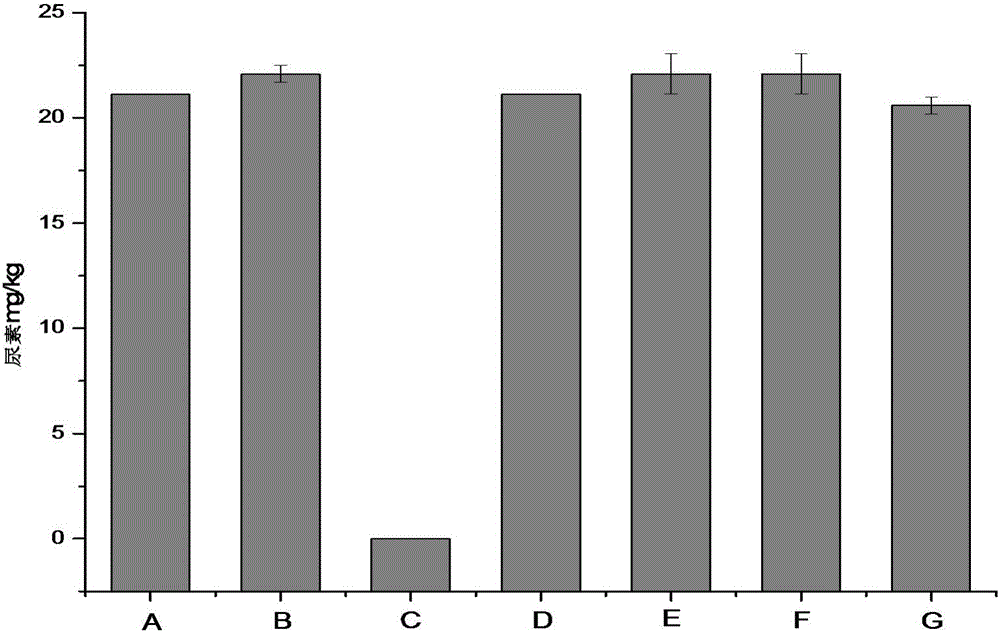

[0030] Example 2 Relation between urea content in liquor fermented grains and adding different bacterial strains

[0031] (1) Preparation of Staphylococcus saprophyticus and Lactobacillus reuteri concentrate

[0032] Three strains of Staphylococcus saprophyticus (Staphylococcus saprophyticus strain M3, Staphylococcus saprophyticus strain M26, and Staphylococcus saprophyticus strain M39) were selected from Baijiu Daqu, respectively, were inserted into the fermentation medium (pH6.8), cultured on a shaker at 30°C and 220rpm for 24h, Collect the thalline by centrifugation, suspend and prepare Staphylococcus saprophytic concentrated bacteria liquid with 0.9% physiological saline (10 9 ~10 10 CFU / mL). Lactobacillus reuteri was inserted into the MRS medium (pH natural), anaerobically cultured for 3 days, and the thalline was collected by centrifugation, and was suspended with 0.9% physiological saline to prepare concentrated bacterial liquid of Lactobacillus reuteri (10 9 ~10 10...

Embodiment 3

[0037] Example 3 Relation between urea content in liquor fermented grains and adding different crude enzyme solutions

[0038] (1) Preparation of crude enzyme solution of Staphylococcus saprophyticus and Lactobacillus reuteri

[0039] Put Staphylococcus saprophyticus into 50mL fermentation medium (pH6.8), culture on a shaker at 30°C at 220rpm for 24h, collect the bacteria by centrifugation, wash the bacteria three times with PBS buffer (pH7.0), suspend to 30mL, add 0.1mm Glass beads were mechanically crushed with FastPrep cell disruptor for 80s, centrifuged at 10,000rpm at 4°C for 10min with a low-temperature refrigerated centrifuge, and the supernatant was obtained. The enzyme activity was 153.9-159.5U / mL. Lactobacillus reuteri was inserted into 200mL MRS medium, cultured anaerobically at 30°C for 3 days, collected by centrifugation, washed with PBS buffer (pH7.0) for 3 times, suspended to 80mL, added with 0.1mm glass beads, and washed with The FastPrep cell disruptor was us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com