Carbon nanofiber composite material with controllable structure and preparation method and application therefor

A carbon nanofiber and composite material technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. Simple, good cycle stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

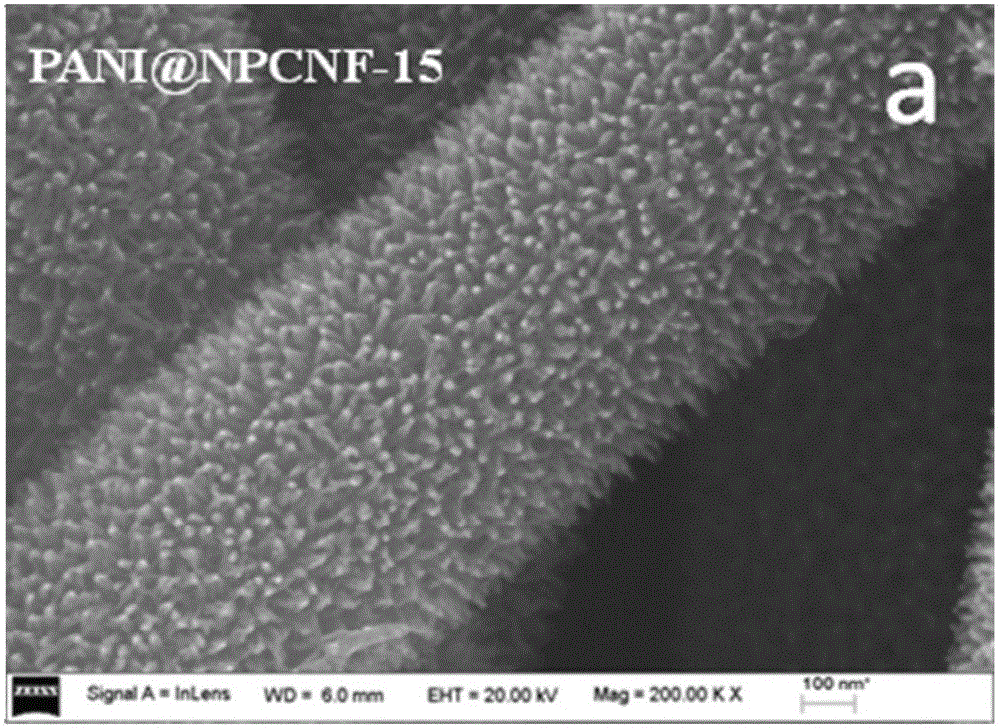

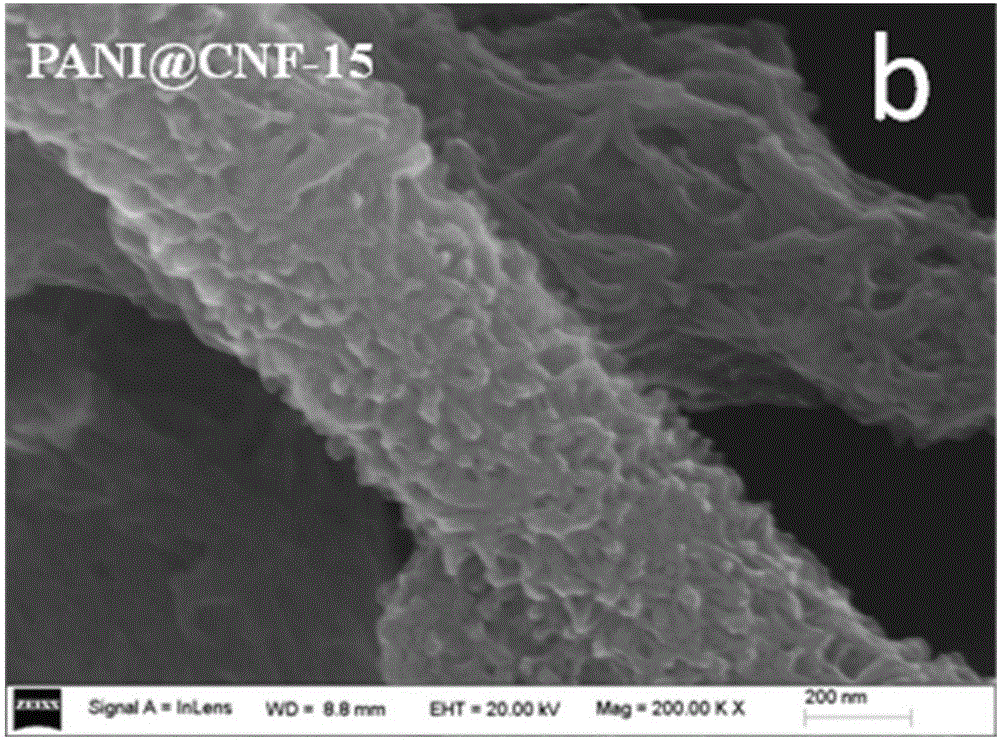

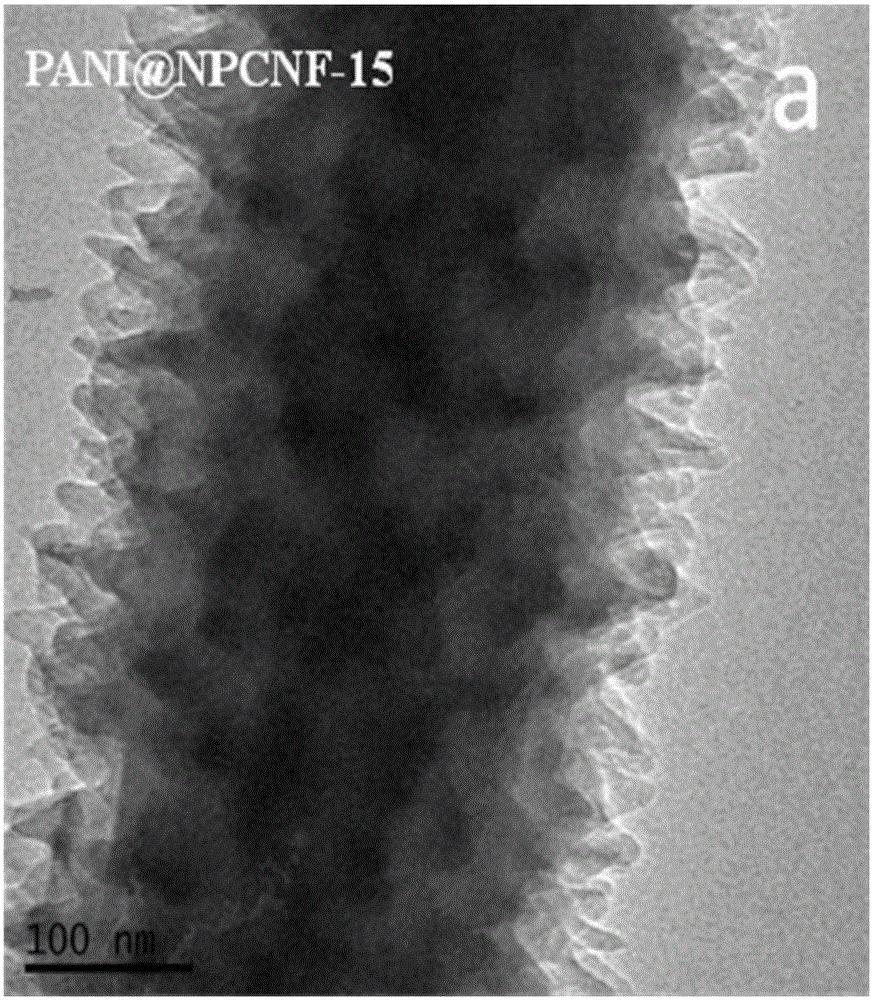

[0033] Dissolve 2g PAN and 0.4g phosphoric acid in DMF to prepare spinning liquid, the electrospinning voltage is 16KV, the injection speed is 0.3mol / h, the rotation speed is 1400r / s, the ambient temperature is kept between 25°C and 30°C, and the humidity is kept Between 20% and 30%. The uniaxial spinning time was 10 hours, and the desired polyacrylonitrile-based nanofiber film was obtained. The resulting spun film was pre-oxidized at 270° C. and carbonized at 800° C. to obtain nitrogen / phosphorus co-doped carbon nanofibers. Soak 0.1g of nitrogen / phosphorus co-doped carbon nanofibers in 200ml of phosphoric acid solution dissolved with 15mmol of aniline monomer, stir for 30 minutes until the nitrogen / phosphorus co-doped carbon nanofibers are well dispersed, and dissolve 200ml with 15mmol of ammonium persulfate (monomer: initiator = 1:1) phosphoric acid solution was slowly added dropwise to ensure that the polymerization reaction temperature was at 0-5°C. After 8 hours of polym...

Embodiment 3

[0036] Dissolve 2gPAN and 0.2g phosphoric acid in DMF to prepare spinning liquid, the electrospinning voltage is 16KV, the injection speed is 0.4mol / h, the rotation speed is 1500r / s, the ambient temperature is kept between 25°C and 30°C, and the humidity is kept Between 20% and 30%. The uniaxial spinning time was 9 hours, and the desired polyacrylonitrile-based nanofiber film was obtained. The resulting spun film was pre-oxidized at 270° C. and carbonized at 800° C. to obtain nitrogen / phosphorus co-doped carbon nanofibers. Soak 0.1g of nitrogen / phosphorus co-doped carbon nanofibers in 200ml of phosphoric acid solution dissolved with 30mmol of aniline monomer, stir for 45 minutes until the nitrogen / phosphorus co-doped carbon nanofibers are well dispersed, and dissolve 200ml with 60mmol of ammonium persulfate (Monomer:initiator=1:2) Phosphoric acid solution is slowly added dropwise to ensure that the polymerization reaction temperature is 0-5°C. After 10 hours of polymerization...

Embodiment 4

[0039] Dissolve 2gPAN and 0.6g phosphoric acid in DMF to make spinning liquid, the electrospinning voltage is 18KV, the injection speed is 0.5mol / h, the rotation speed is 1600r / s, the ambient temperature is kept between 25°C and 30°C, and the humidity is kept Between 20% and 30%. The uniaxial spinning time was 10 hours, and the desired polyacrylonitrile-based nanofiber film was obtained. The resulting spun film was pre-oxidized at 270° C. and carbonized at 800° C. to obtain nitrogen / phosphorus co-doped carbon nanofibers. Soak 0.1g of nitrogen / phosphorus co-doped carbon nanofibers in 200ml of phosphoric acid solution dissolved with 5mmol of aniline monomer, stir for 60 minutes until the nitrogen / phosphorus co-doped carbon nanofibers are well dispersed, and dissolve 200ml with 20mmol of ammonium persulfate (Monomer: initiator = 1:4) phosphoric acid solution was slowly added dropwise to ensure that the polymerization temperature was 0-5°C. After 11 hours of polymerization, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com