Preparation method of graphene

A graphene, graphene solution technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of reducing the specific surface area of materials, agglomeration and stacking, etc., to improve specific capacity, reduce interface resistance, achieve The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 100ml of graphene oxide aqueous solution with a concentration of 3mg mL-1, add 100mg of citric acid, and sonicate for 1h; according to the volume ratio of graphene solution to oil phase of 1:0.2, add methyl methacrylate and stir for 20min to prepare oxidation Graphene emulsion; heat the emulsion at 180°C for 3h to obtain the precursor; freeze-dry the precursor, and then react for 2h at 800°C in a nitrogen environment; take the reaction product to repeatedly wash with deionized water and dry, Get the graphene material.

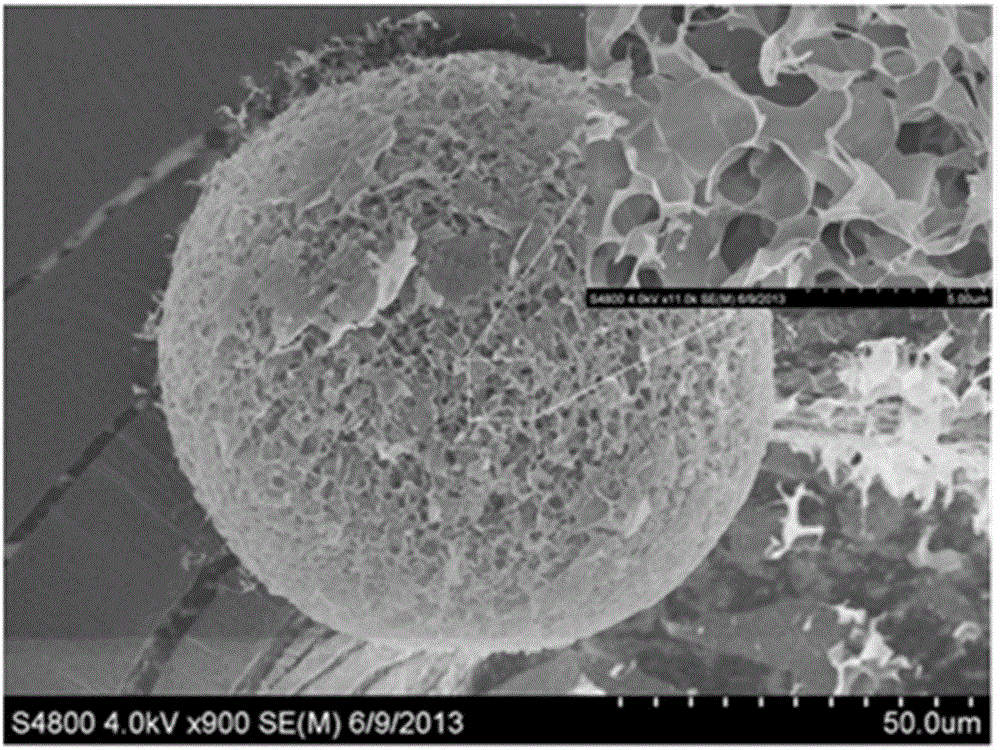

[0037] The graphene prepared in this example is subjected to scanning electron microscopy (SEM), such as figure 1 As shown, it can be seen that graphene has a porous, internal cross-linked spherical structure, which is conducive to electrolyte diffusion and transmission, and this internal cross-linked layered structure as a conductive network is conducive to the transmission of electrons.

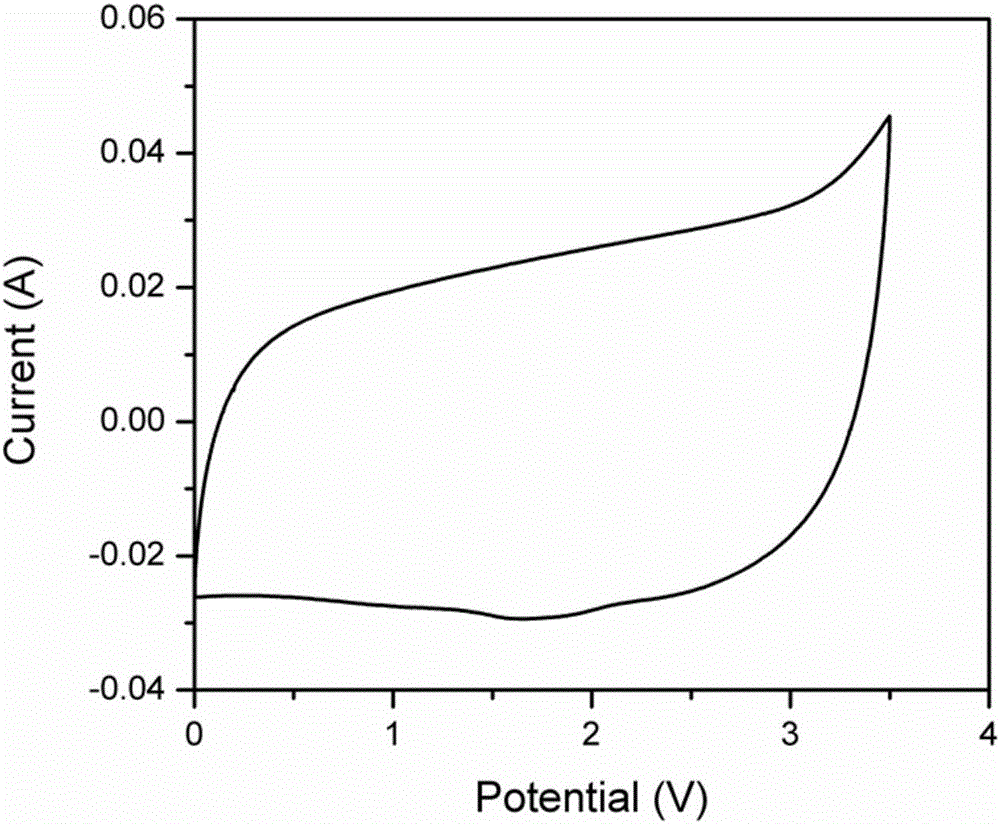

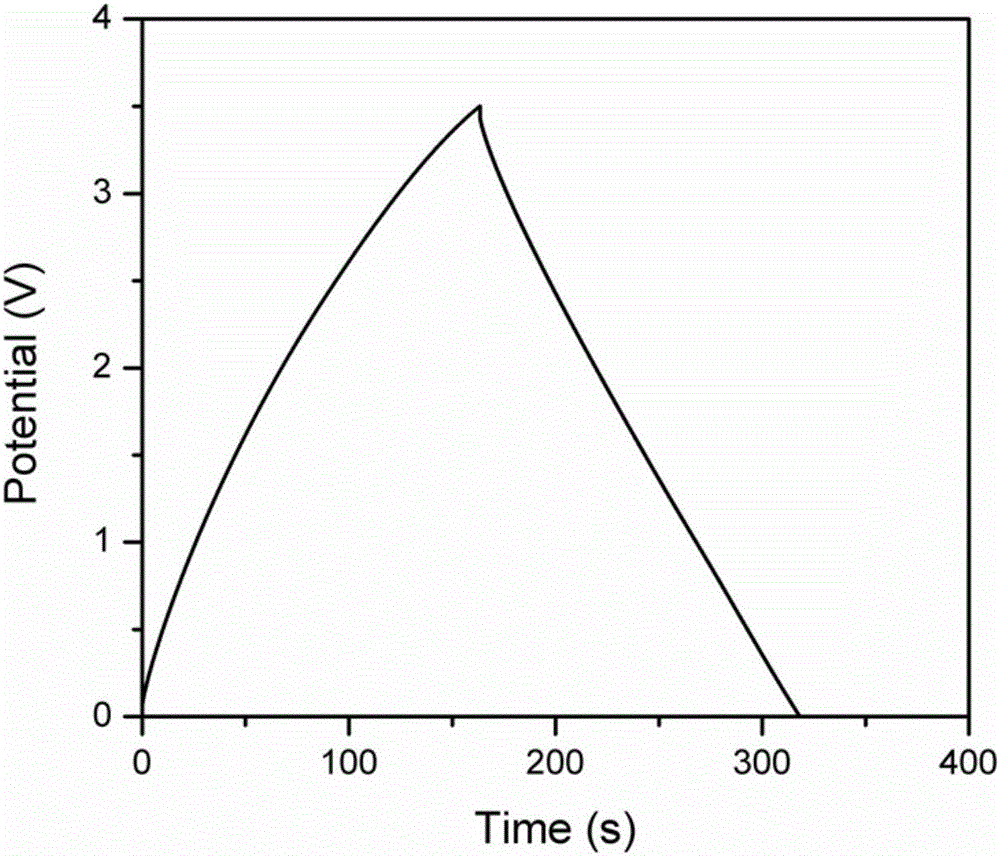

[0038] Weigh 80 mg of the graphene prepared in this example, 10 ...

Embodiment 2

[0040] Take 100ml of graphene oxide aqueous solution with a concentration of 0.5mg mL-1, add 50mg of citric acid, and ultrasonically treat for 1.5h; according to the volume ratio of graphene solution to oil phase of 1:0.5, add ethyl methacrylate and stir for 15min. Obtain graphene oxide emulsion; heat the emulsion at 190°C for 1 hour to obtain the precursor; freeze-dry the precursor, and then react in a nitrogen environment at 900°C for 3 hours; take the reaction product to repeatedly wash with deionized water and bake Dry to obtain graphene material.

Embodiment 3

[0042] Take 100ml of graphene oxide aqueous solution with a concentration of 4mg mL-1, add 200mg of citric acid, and ultrasonically treat for 0.5h; according to the volume ratio of graphene solution to oil phase of 1:2, add methyl methacrylate and stir for 5min to prepare. Graphene oxide emulsion; heat the emulsion at 200°C for 0.5h to obtain the precursor; freeze-dry the precursor, and then react for 1h at 1000°C in a nitrogen environment; take the reaction product to repeatedly wash with deionized water and bake Dry to obtain graphene material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com