Surface modification method of carbon cloth for supercapacitor electrodes

A supercapacitor and surface modification technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of reduced comprehensive properties of materials, poor oxidation effect, and damage to the fiber body, so as to achieve low cost and improve activity. and roughness, time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 4g of LiNO 3 , was dissolved in 10 mL of distilled water to form a homogeneous solution, and the carbon cloth was impregnated in LiNO 3 Once in the solution, take it out and place it in an 80°C drying oven to dry and recrystallize for 24h, then wash it, put it in a tube furnace, and set it in an Ar atmosphere at 5°C·min -1 The heating rate was increased to 750°C, and the temperature was kept constant for 120 minutes. After cooling, it was washed with distilled water to remove inorganic salts, and then dried to obtain a surface-modified carbon cloth.

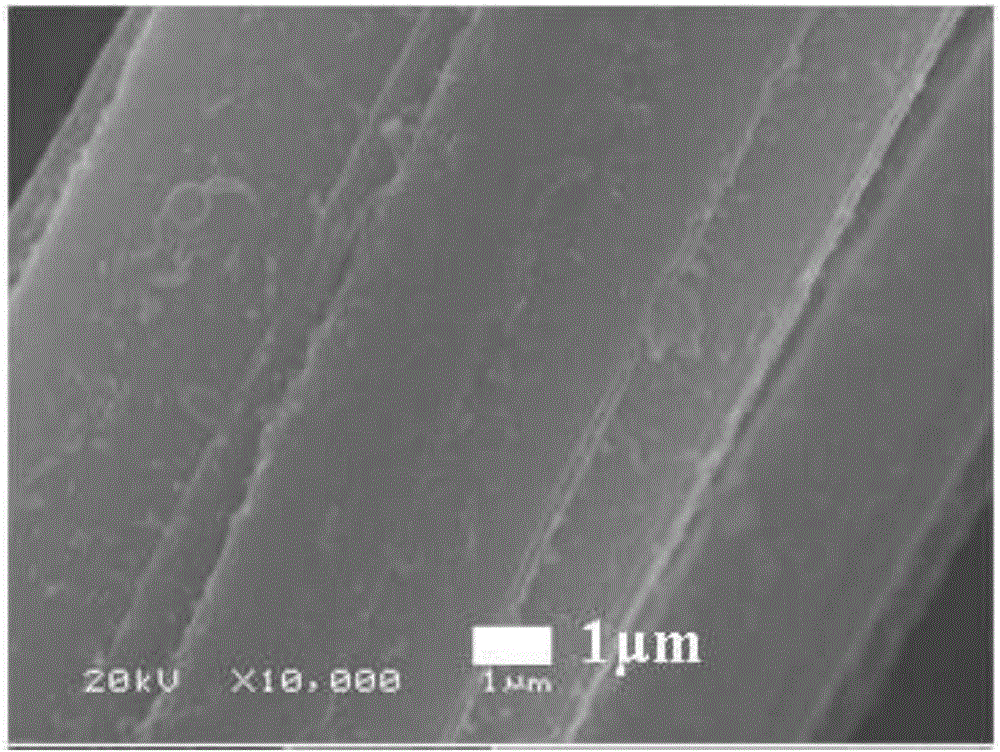

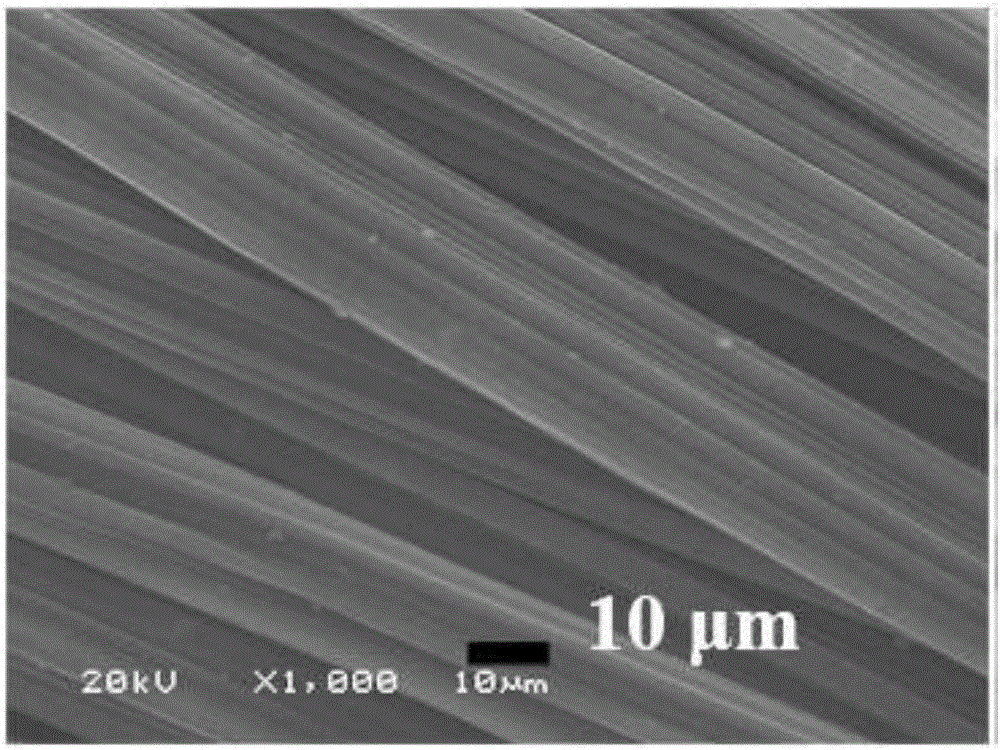

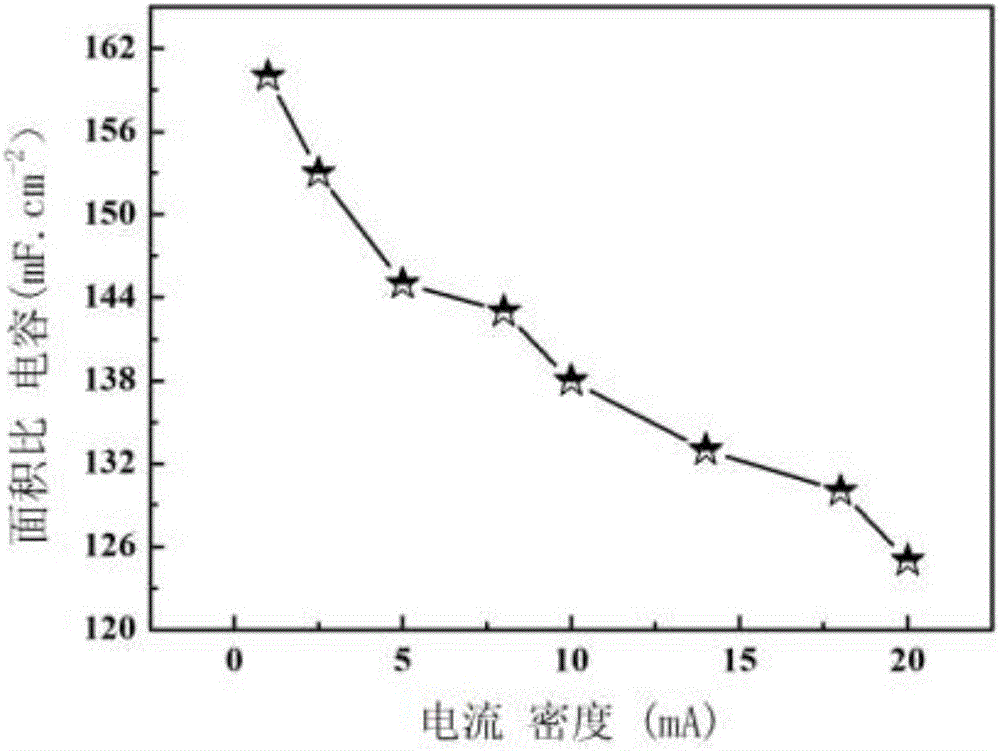

[0025] The scanning electron micrograph of the carbon cloth prepared in this embodiment is as follows: figure 1 As shown, the scanning electron micrographs of the unmodified carbon cloth are as follows figure 2 As shown, it can be seen that the surface of the unmodified carbon cloth is smooth, and the surface of the modified carbon cloth is rough. Supercapacitor test was carried out on the prepared modified carbo...

Embodiment 2

[0027] Weigh 4g of Li 2 SO 4 , was dissolved in 10 mL of distilled water to form a homogeneous solution, and the carbon cloth was impregnated in Li 2 SO 4 solution twice, take it out and put it in an 80°C drying oven to dry and recrystallize for 24 hours, then wash it, put it in a tube furnace, and set it in an Ar atmosphere at 5°C·min -1 The heating rate was raised to 750°C, and the temperature was kept constant for 120 minutes. After cooling, it was washed with distilled water to remove inorganic salts, and then dried to obtain a surface-modified carbon cloth. At a discharge current density of 1mA, the specific capacitance was 180mF·cm -2 , the capacitance remains at 150mF·cm at 20mA -2 .

Embodiment 3

[0029] Weigh 4g of Na 2 S 2 o 3 , dissolved in 10 mL of distilled water to form a uniform solution, impregnated the carbon cloth in Na 2 S 2 o 3 solution once, put it in an 80°C drying oven to dry and recrystallize for 24h, then wash it, put it in a tube furnace, under Ar atmosphere, at 5°C·min -1 The heating rate was increased to 750°C, and the temperature was kept constant for 120 minutes. After cooling, it was washed with distilled water to remove inorganic salts, and dried to obtain a surface-modified carbon cloth with a specific capacity of 200mF·cm at a discharge current density of 1mA. -2 , the capacitance remains at 160mF·cm at 20mA -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com