Growth method for current expansion layer and LED epitaxial structure comprising current expansion layer

A technology of a current spreading layer and a growth method, applied in the field of LED epitaxial structure, can solve the problems of current crowding, low luminous efficiency, and high resistance of the N layer, and achieve uniform current distribution, simplified process flow, and convenient parameter control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

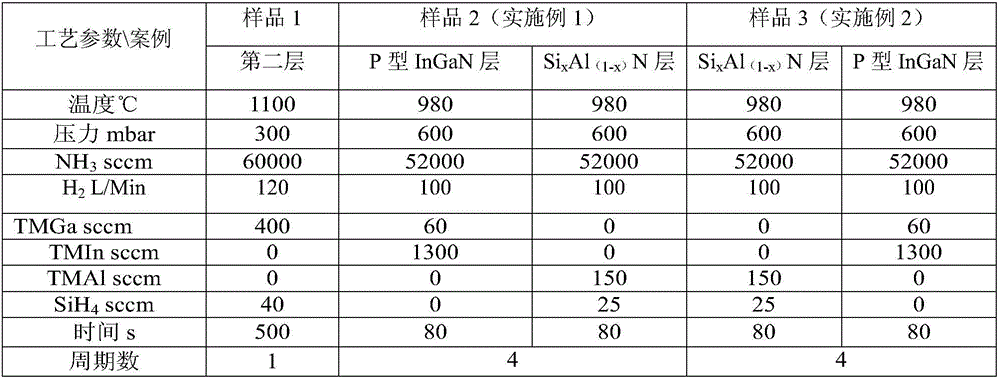

[0048] Use MOCVD to grow high-brightness GaN-based LED epitaxial wafers, specifically: use high-purity H 2 or high purity N 2 or high purity H 2 and high purity N 2 The mixed gas as the carrier gas, high-purity NH 3 As the N source, the metal-organic source trimethylgallium (TMGa) is used as the gallium source, trimethylindium (TMIn) is used as the indium source, and the N-type dopant is silane (SiH 4 ), trimethylaluminum (TMAl) as the aluminum source P-type dopant is dimagnesocene (CP 2 Mg), the substrate is sapphire, and the reaction pressure is between 70mbar and 900mbar.

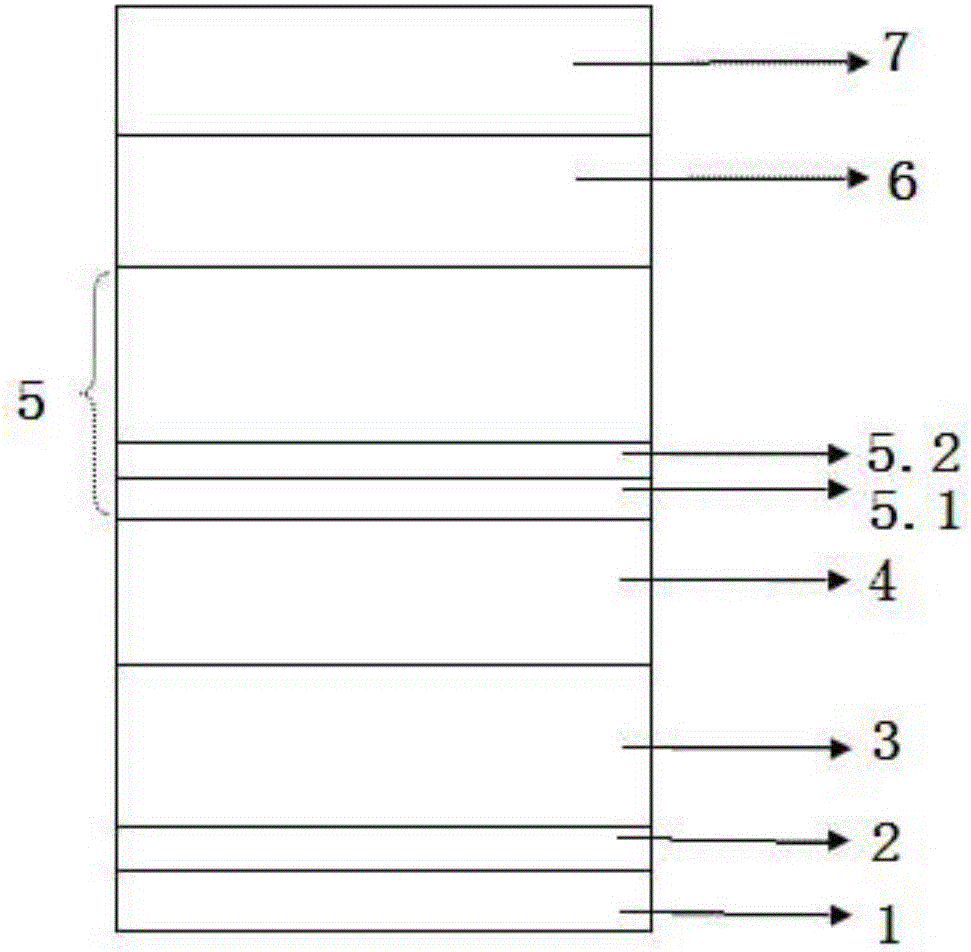

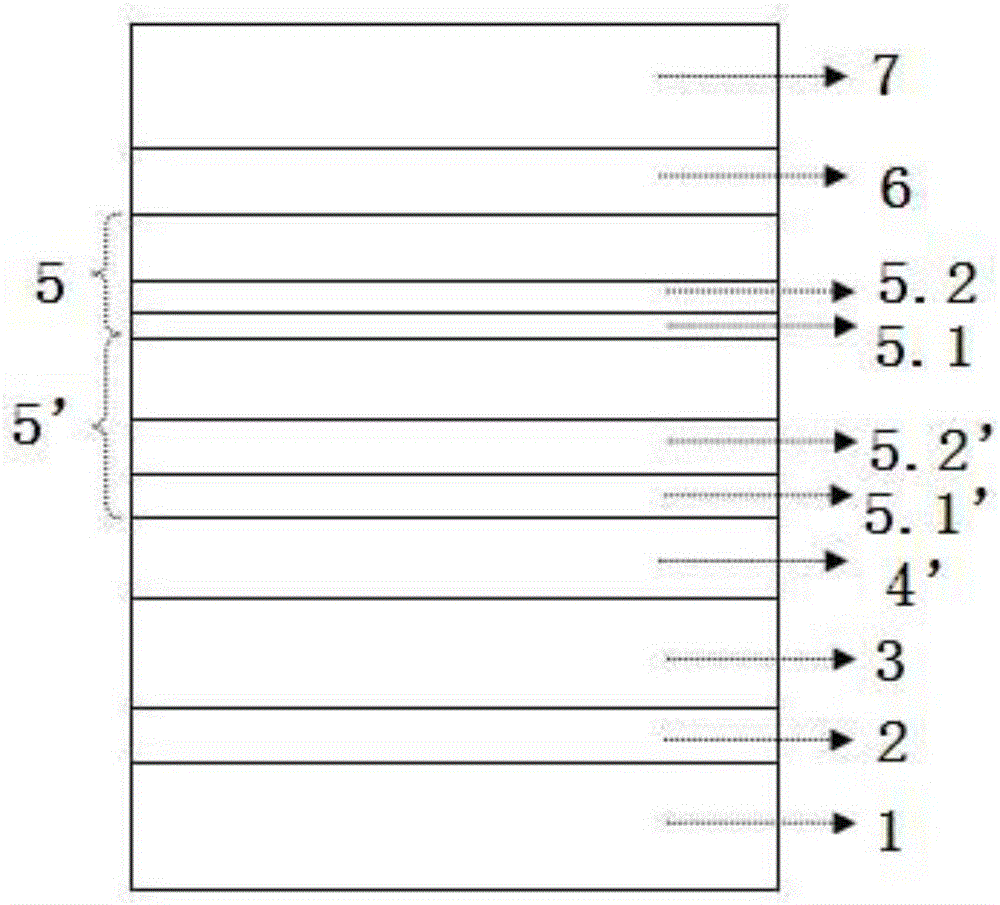

[0049] An LED epitaxial structure, see figure 2 , including the following structure: from bottom to top, it includes a sapphire substrate 1, a low-temperature buffer layer 2, an undoped GaN buffer layer 3, a Si-doped N-type GaN single layer 4', a current spreading layer 5', a light emitting layer 5, p-type AlGaN layer 6 and p-type GaN layer 7 doped with magnesium;

[0050] The thickness of the lo...

Embodiment 2

[0071] The only difference from Embodiment 1 is that the current spreading layer 5' includes four individual pieces, and the individual pieces include Si from bottom to top. x Al (1-x) N and P-type InGaN layers, where x=0.20.

Embodiment 3

[0073] The only difference from Embodiment 1 is that the current spreading layer 5' comprises 8 single pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com