Mesoporous perovskite solar cell

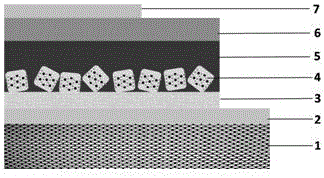

A technology for solar cells and perovskites, applied in the field of solar cells, can solve the problems of difficult penetration of perovskite, incomplete penetration of perovskite, and low cell efficiency, and achieve the effect of improving cell efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

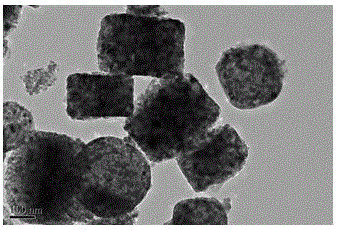

[0027] Weigh 3 grams of terephthalic acid, add it to 54 milliliters of N,N-dimethylformamide, add 6 milliliters of anhydrous methanol, add 1.56 milliliters of tetra-n-butyl titanate dropwise under stirring, and stir for 30 minutes . Then the mixture was transferred into a polytetrafluoroethylene autoclave and kept at 150°C for 24 hours. After the reaction was finished, the precipitate was washed three times with methanol, and dried at 50° C. for 1 hour to obtain a white powder. Then the above white powder was calcined at 380 degrees Celsius for 3 hours in the air environment to fully remove the organic matter. Then heat up to 480 degrees Celsius for 0.5 hours to form a porous multi-level titanium dioxide nanomaterial, figure 2 It is a transmission electron micrograph of the porous hierarchical titanium dioxide nanomaterial. Then, after the above-mentioned porous titanium dioxide nanomaterial was ground in a mortar for 1 hour, 0.5 g was weighed and ultrasonically dispersed ...

Embodiment 2

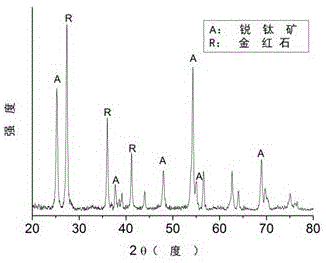

[0032] Weigh 3 grams of terephthalic acid, add it to 54 milliliters of N,N-dimethylformamide, then add 6 milliliters of anhydrous methanol, add 1.56 milliliters of tetra-n-butyl titanate dropwise under stirring, and stir for 60 minutes . Then the mixture was transferred into a polytetrafluoroethylene autoclave and kept at 120°C for 20 hours. After the reaction, the precipitate was washed with methanol for 5 times, and dried at 100° C. for 1 hour to obtain a white powder. Then the above white powder was calcined at 350°C for 5 hours in the air environment to fully remove the organic matter. Then heat up to 500 degrees Celsius for 1 hour to form a porous multi-level structure titanium dioxide nanomaterial with anatase phase and rutile phase mixed crystal, image 3 is its X-ray diffraction pattern. Then, after grinding the porous hierarchical titanium dioxide nanomaterial in a mortar for 1 hour, weigh 0.5 g and ultrasonically disperse it into 1 ml of ethanol, then add 0.5 ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com