Preparation method of PtPd/Fe3O4 (platinum-palladium/ferroferric oxide) nanocatalyst and application thereof in HECK reaction

A nano-catalyst and nano-technology, applied in the direction of physical/chemical process catalysts, catalysts, carbon compound catalysts, etc., can solve the problems of poor economy, low recycling rate, and low practical value, and achieve simple preparation process and recycling. The effect of convenience and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

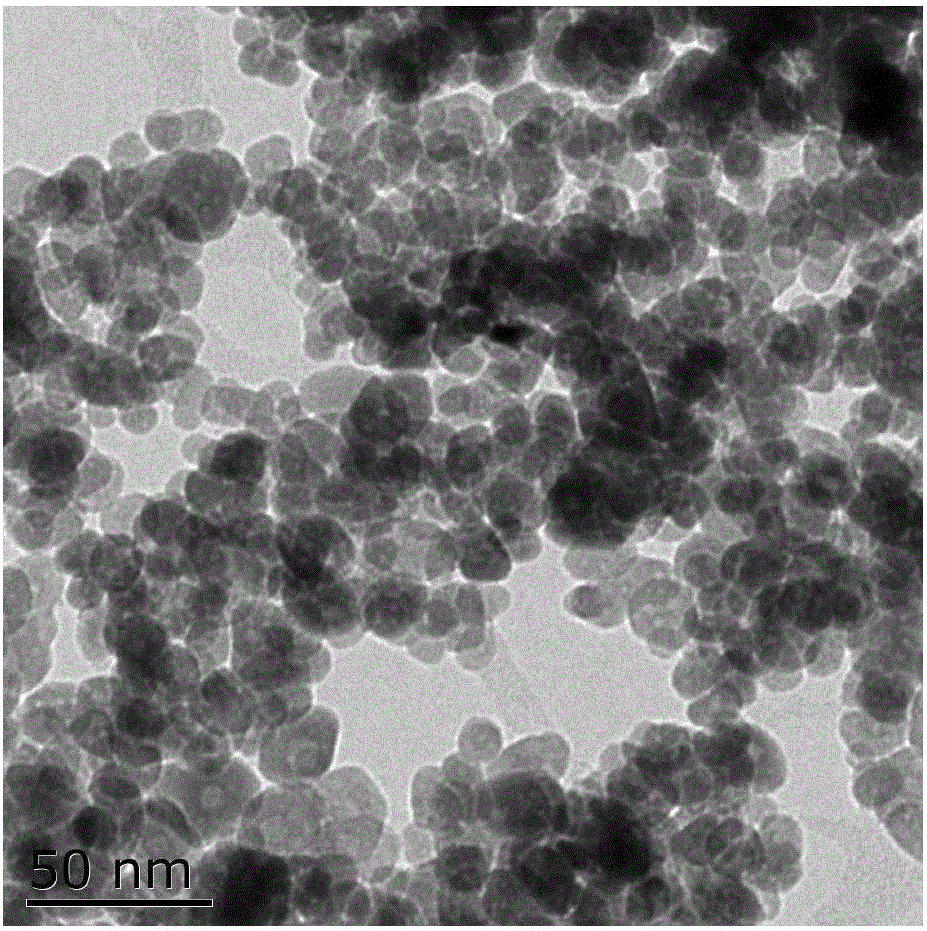

[0039] Example 1: PtPd / Fe 3 o 4 Preparation of nanocatalysts

[0040] (1) Preparation of carrier and its pretreatment

[0041] In a 50ml beaker, accurately weigh 0.2125g of FeCl 3 ·6H 2The urea of 0,0.1432g, the polyvinylpyrrolidone of 0.1663g, then add the 1 of 8.5ml, the 2-propanediol, the mixture is stirred on the magnetic stirrer until the solution is mixed and transferred in the reaction kettle after obtaining the yellow transparent solution, after sealing React at 190°C for 16h. After the reaction, cool to room temperature, transfer the product to a wide-mouth glass bottle, wash with deionized water and ethanol several times, and use magnetic separation to pour out the supernatant in the wide-mouth bottle. Disperse the washed black precipitated particles in 10 mL of ethanol to obtain Fe 3 o 4 Nanomagnetic materials.

[0042] (2) Preparation of Pt-Pd sol

[0043] In a 50ml beaker, accurately weigh 0.0789g of polyvinylpyrrolidone, measure 3.86×10 -3 mol / L aqueo...

Embodiment 2

[0046] Example 2: PtPd / Fe 3 o 4 Applications of nanocatalysts

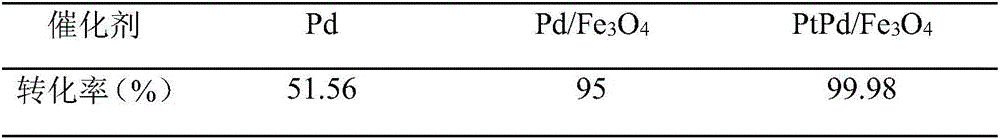

[0047] Application of Pt-Pd Magnetic Nano-Supported Catalysts in Heck Reaction

[0048] Add 0.16mL of iodobenzene, 3mL of DMF, 0.20mL of styrene, the Pt-Pd magnetic nano-loaded catalyst prepared above into a 100ml three-necked flask, stir well and then add 0.2764g of K 2 CO 3 , with electric stirring at 90 °C for 9 h. After the reaction, the catalyst was separated from the product, and the catalyst was left for recycling. The results are shown in Table 1. As can be seen from Table 1, PtPd / Fe 3 o 4 The conversion rate of nanometer catalyst to iodobenzene is about 100%, and the conversion rate drops significantly after the catalyst is recycled for 4 times.

[0049] Wherein the conversion rate is calculated by reactant iodobenzene gas phase peak area: iodobenzene initial peak area S 1 , the iodobenzene peak area S after the reaction 2 , then the conversion rate is: (S 1 -S 2 ) / S 1 .

[0050] Table 1 PtPd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com