Method for preparing monodisperse silica sol by utilizing gas-liquid-solid three-phase slurry reactor

A slurry reactor, gas-liquid-solid technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as the dispersibility of silicon powder and silica sol particles that are not involved, and achieve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

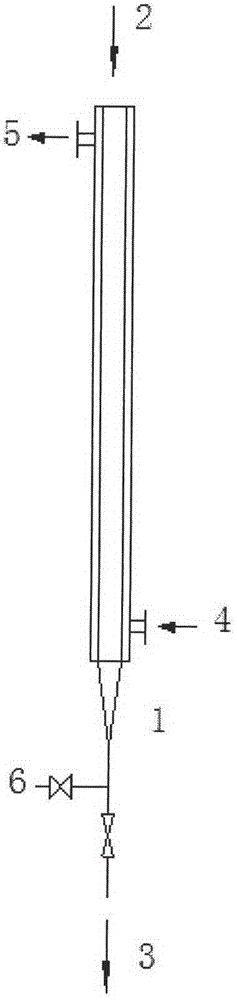

[0024] A kind of method utilizing gas-liquid-solid three-phase slurry reactor to prepare monodisperse silica sol, its component counts in parts by mass, comprises the following process steps:

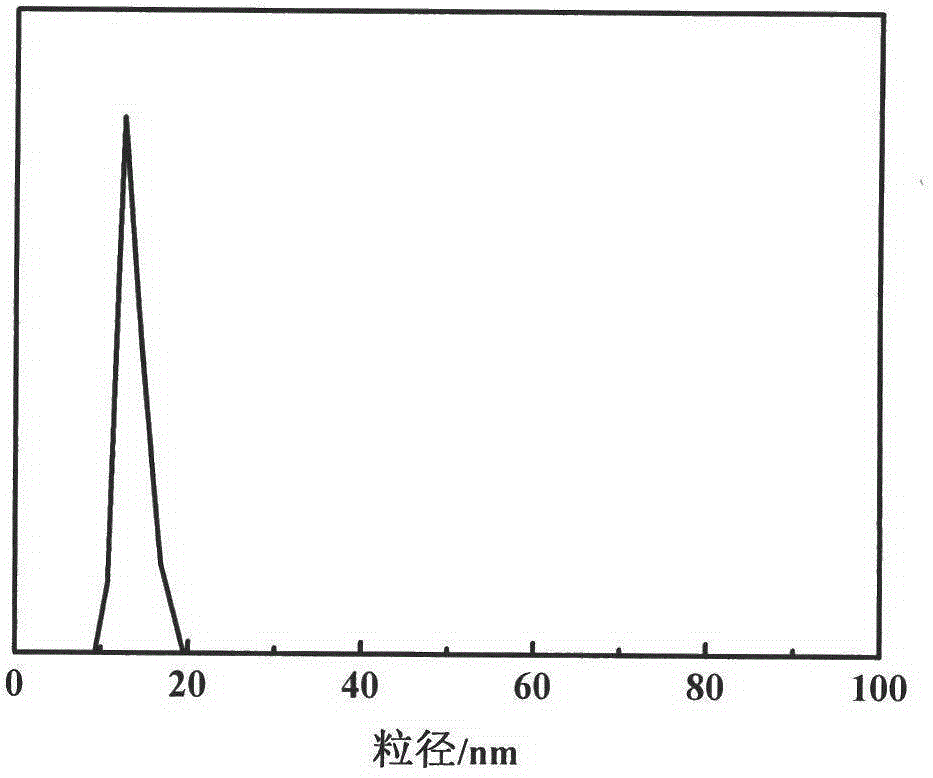

[0025] The length-to-diameter ratio of the gas-liquid-solid three-phase slurry reactor is 50:1; the silicon powder particle size is 100 mesh, and the addition amount is 7 parts, which are added in 3 times with an interval of 20 minutes each time; It is composed of 99.95 parts of water, and the liquid feeding rate is 0.5mL / min; the mass ratio of silicon powder and alkali is 10:1; the reaction temperature is 50°C, and the reaction is kept for 2 hours after stopping the feeding of alkali solution. The obtained silica sol has a particle size of 13 nm and a polydispersity index of 0.021. figure 2 It is the particle size distribution diagram of the silica sol obtained under the present embodiment.

Embodiment 2

[0027] A kind of method utilizing gas-liquid-solid three-phase slurry reactor to prepare monodisperse silica sol, its component counts in parts by mass, comprises the following process steps:

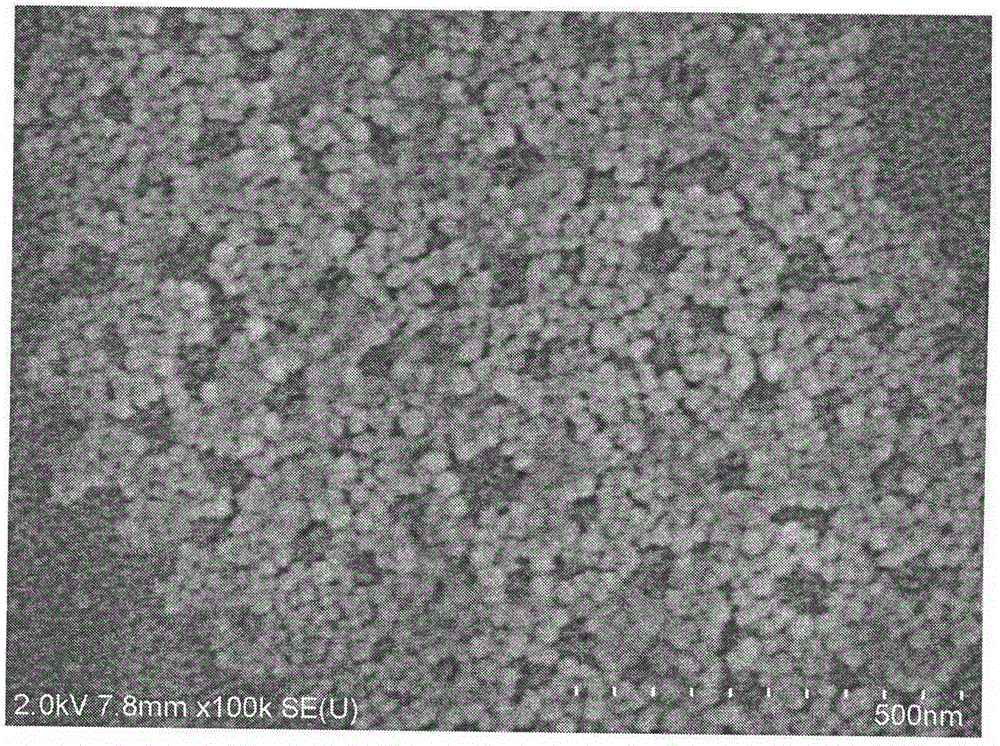

[0028] The length-to-diameter ratio of the gas-liquid-solid three-phase slurry reactor is 250:1; the particle size of silicon powder is 200 mesh, and the addition amount is 50 parts, which is added in 4 times with an interval of 120 minutes; It is composed of 99 parts of water, and the liquid feeding rate is 5mL / min; the mass ratio of silicon powder and alkali is 20:1; the reaction temperature is 70°C, and the reaction is kept for 10 hours after stopping the feeding of alkali solution. The obtained silica sol has a particle size of 20 nm and a polydispersity index of 0.012. image 3 It is the scanning electron micrograph of the silica sol obtained under the present embodiment.

Embodiment 3

[0030] A kind of method utilizing gas-liquid-solid three-phase slurry reactor to prepare monodisperse silica sol, its component counts in parts by mass, comprises the following process steps:

[0031] The length-to-diameter ratio of the gas-liquid-solid three-phase slurry reactor is 100:1; the particle size of silicon powder is 600 mesh, and the addition amount is 100 parts, which is added in 6 times with an interval of 80 minutes each time; , 1 part KOH, 0.5 part NH 4 Composed of OH and 97.5 parts of water, the liquid feed rate is 2mL / min; the mass ratio of silicon powder and alkali is 50:1; the reaction temperature is 90°C, and the reaction is kept for 12 hours after stopping the feeding of alkali solution. The obtained silica sol has a particle size of 50 nm and a polydispersity index of 0.036. Figure 4 It is the scanning electron micrograph of the silica sol obtained under the present embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com