Mesoporous trimanganese tetraoxide and preparation method thereof

A technology of manganese tetroxide and manganese tetroxide material, applied in the field of nanomaterials, can solve the problems of high energy consumption, complicated preparation process and high production cost, and achieve the effects of high safety, easy availability of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

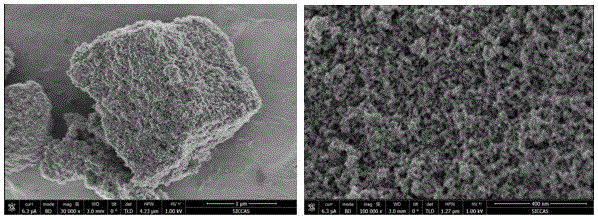

Examples

Embodiment 1

[0028] At room temperature, mix 200 mL of 0.0056 mol / L mannitol aqueous solution with 40 mL of 0.187 mol / L potassium permanganate aqueous solution, stir or sonicate until the purple color of the solution disappears;

[0029] Then add 0.35 mL hydrazine hydrate (50%) while stirring, and react for a period of time (0.2~3 h);

[0030] Filter, wash (with deionized water, alcohol) 3 to 5 times, and dry at 80°C to obtain trimanganese tetraoxide.

[0031] Electrochemical performance test:

[0032] Using the trimanganese tetraoxide sample prepared in this example as the active material, acetylene black (AB) as the conductive agent, and polytetrafluoroethylene (PTFE) as the binder, Mn 3 o 4 : AB: PTFE (mass ratio) = 8: 1.5: 0.5, making electrode materials for supercapacitors. The specific steps are as follows: the active material, acetylene black and PTFE are mixed and fully ground, then N-methyl-2-pyrrolidone (NMP) is added dropwise, ground into a paste, evenly coated on a stainless...

Embodiment 2

[0042] At room temperature, mix 200 mL of 0.0041 mol / L mannitol aqueous solution with 40 mL of 0.187 mol / L potassium permanganate aqueous solution;

[0043] All the other steps are the same as in Example 1.

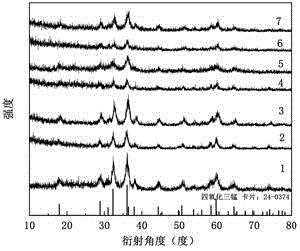

[0044] figure 1 2 curves in the XRD spectrum of the sample obtained in this example.

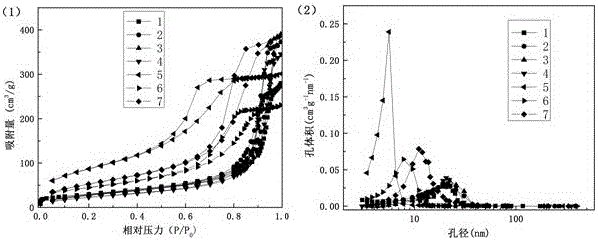

[0045] image 3 2 curves in the example are the nitrogen adsorption, desorption isotherm curve and pore size distribution figure of the sample prepared in this example;

[0046] 2 in Table 1 is the specific surface area, pore diameter and specific capacitance value of the sample prepared in this example.

[0047] Through the above analysis and calculation, it is known that the morphology and structure of the sample obtained in this example are basically the same as in Example 1, the difference is that the specific surface area and pore diameter of the sample obtained in this example are respectively 128 m2 / g and 19.3 nm. As a supercapacitor electrode material: its specific capacita...

Embodiment 3

[0049] At room temperature, mix 200 mL of 0.0049 mol / L mannitol aqueous solution with 40 mL of 0.187 mol / L potassium permanganate aqueous solution;

[0050] All the other steps are the same as in Example 1.

[0051] figure 1 The 3 curve among is the XRD pattern of samples obtained in this example.

[0052] image 3 3 curves in this example are the nitrogen adsorption, desorption isotherm curve figure and pore size distribution figure of the sample made in this example;

[0053] 3 in Table 1 is the specific surface area, pore diameter and specific capacitance value of the sample prepared in this example.

[0054] Through the above analysis and calculation, it is known that the morphology and structure of the sample obtained in this example are basically the same as in Example 1, the difference is that the specific surface area and pore diameter of the sample obtained in this example are respectively 112 m 2 / g and 22.2 nm. As a supercapacitor electrode material: its specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com