Polyhydroxy polyamine surface activity initiator and preparing method thereof

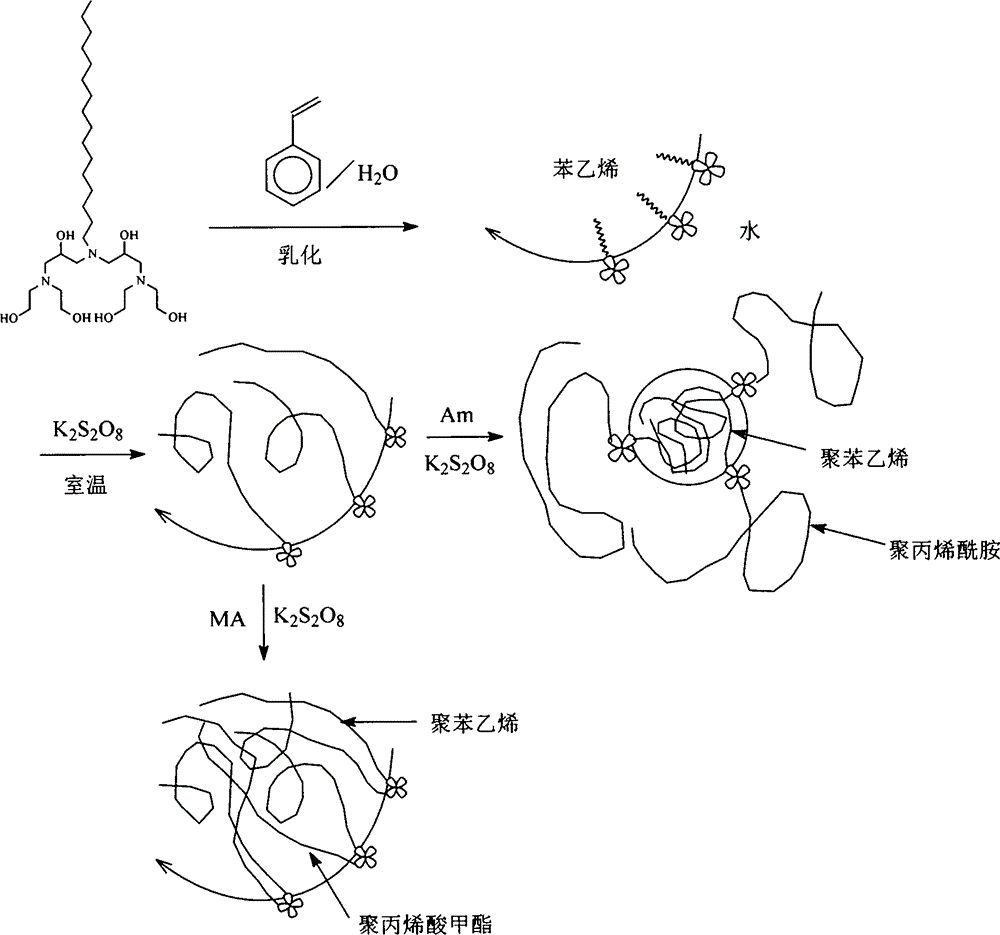

A polyhydroxy polyamine and surface active technology, which is applied in the preparation of amino hydroxyl compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of limited application value, inability to achieve cross-phase polymerization, and inability to popularize in large quantities. Achieve the effect of pure product, mild and controllable polymerization reaction conditions, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

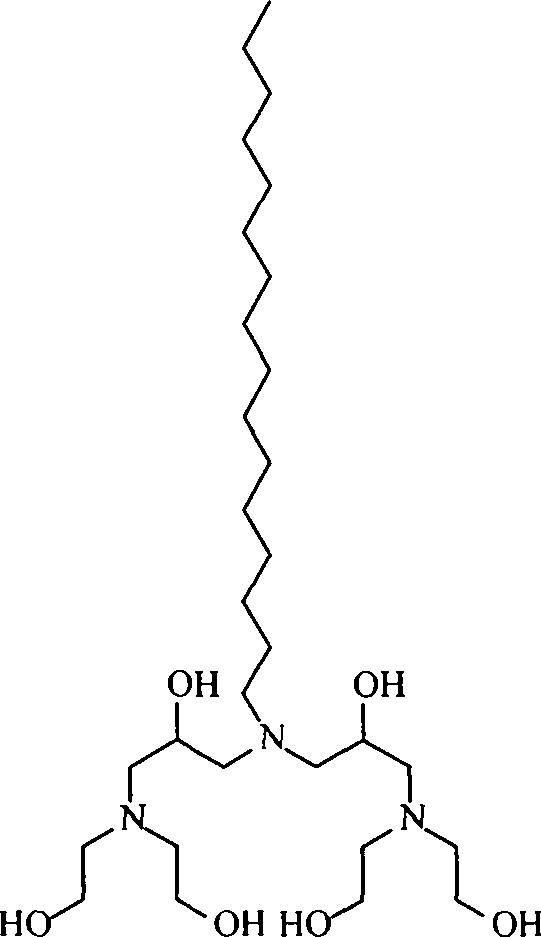

[0020] Preparation of polyhydroxy polyamine surfactant initiator:

[0021] 1. Dissolve cetylamine in absolute ethanol, control the weight ratio of cetylamine to ethanol in the range of 1:3~1:3.5, then add epichlorohydrin and keep stirring, cetylamine and epichlorohydrin Keep the molar ratio of 1:2 as much as possible, control the temperature of the system in the range of 25-30°C, and the reaction time should reach 15-16 hours;

[0022] 2. Add diethanolamine and sodium hydroxide to the above reaction mixture, the moles of diethanolamine and sodium hydroxide should be the same as the moles of epichlorohydrin above, and gradually raise the reaction temperature to 60-70°C while stirring, At this time, a white precipitate is precipitated, which is the fine crystals of NaCl produced by the reaction. React at this temperature for 3 to 4 hours. After gradually cooling, the NaCl crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com