Water-based environment-friendly epoxy anticorrosive primer and method for preparing same

A technology of anti-corrosion primer and water-based epoxy resin, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effects of not easy to pulverize, high strength, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

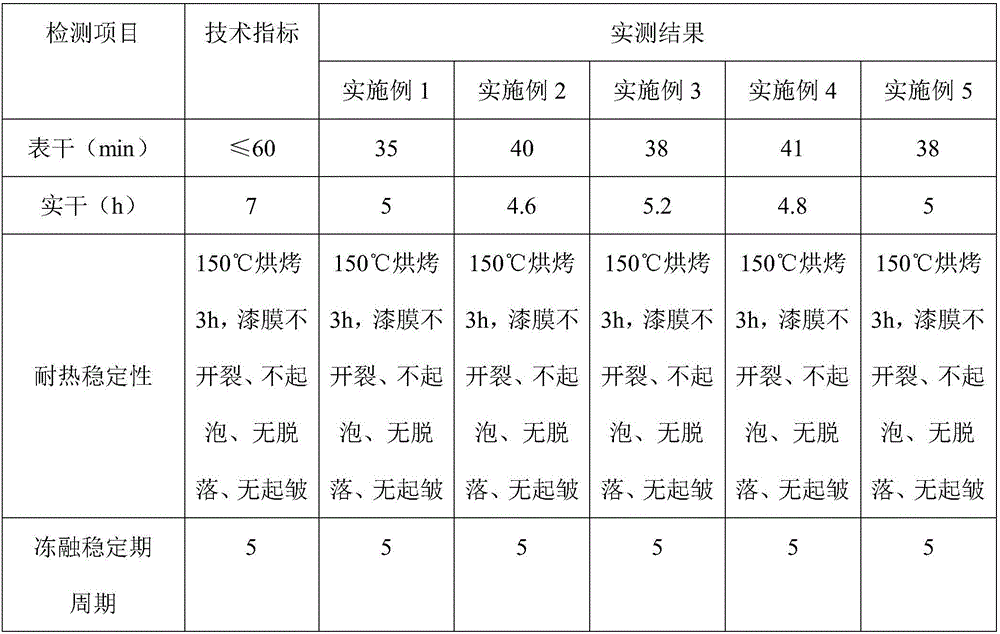

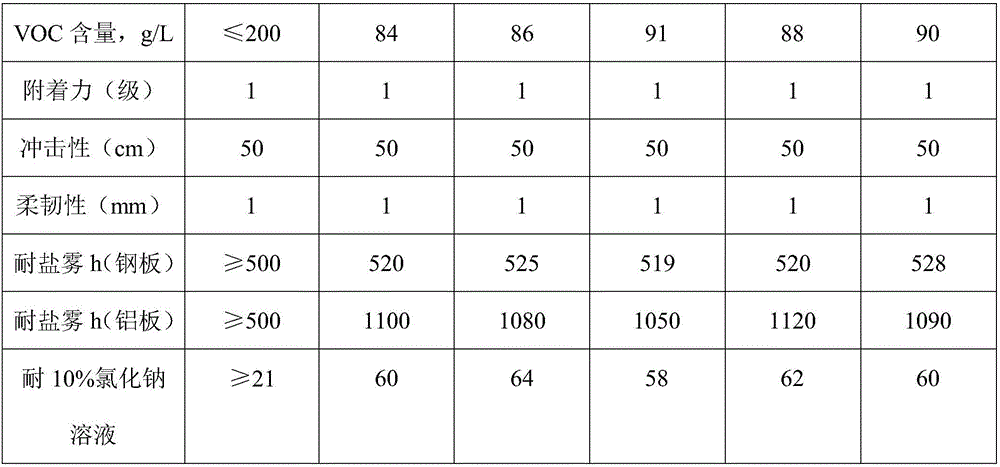

Examples

Embodiment 1

[0025] A water-based environmental protection epoxy anti-corrosion primer, which is composed of the following raw materials in parts by weight: 45 parts of water-based epoxy resin emulsion, 20 parts of fluorocarbon emulsion, 30 parts of filler, 10 parts of antirust pigment, 20 parts of deionized water, silane 3 parts of joint agent, 0.4 parts of preservative, 10 parts of ketimine resin, 30 parts of water-based epoxy curing agent, 8 parts of flake mica powder, 3 parts of titanium dioxide, 3 parts of dispersant, 2 parts of accelerator, 0.5 parts of leveling agent 0.5 parts of antifoaming agent, 0.2 parts of wetting and dispersing agent, 2 parts of talcum powder, 1 part of fatty amine, 0.1 part of penetrating agent, 10 parts of glutinous rice noodles, 0.5 parts of Bletilla striata, 1 part of Poria cocos, 3 parts of mugwort leaves, goose but not food Grass 1 part.

[0026] The preparation method of described water-based environmental protection epoxy anticorrosion primer, concrete...

Embodiment 2

[0034] A water-based environmental protection epoxy anti-corrosion primer, which is composed of the following raw materials in parts by weight: 48 parts of water-based epoxy resin emulsion, 22 parts of fluorocarbon emulsion, 32 parts of filler, 11 parts of antirust pigment, 25 parts of deionized water, silane 3.5 parts of joint agent, 0.45 parts of preservative, 11 parts of ketimine resin, 35 parts of water-based epoxy curing agent, 9 parts of flake mica powder, 3.5 parts of titanium dioxide, 3.5 parts of dispersant, 2.5 parts of accelerator, and 0.6 parts of leveling agent 0.6 parts of antifoaming agent, 0.25 parts of wetting and dispersing agent, 2.5 parts of talcum powder, 1.2 parts of fatty amine, 0.15 parts of penetrating agent, 11 parts of glutinous rice noodles, 0.55 parts of Bletilla striata, 1.1 parts of poria cocos, 3.5 parts of mugwort leaves, goose but food Grass 2 parts.

[0035] The preparation method of described water-based environmental protection epoxy antico...

Embodiment 3

[0043] A water-based environmental protection epoxy anti-corrosion primer, which is composed of the following raw materials in parts by weight: 50 parts of water-based epoxy resin emulsion, 25 parts of fluorocarbon emulsion, 35 parts of filler, 12 parts of antirust pigment, 30 parts of deionized water, silane 4 parts of joint agent, 0.5 parts of preservative, 12 parts of ketimine resin, 40 parts of water-based epoxy curing agent, 10 parts of flake mica powder, 4 parts of titanium dioxide, 4 parts of dispersant, 3 parts of accelerator, and 0.8 parts of leveling agent 0.8 parts of antifoaming agent, 0.3 parts of wetting and dispersing agent, 3 parts of talcum powder, 1.5 parts of fatty amine, 0.2 parts of penetrating agent, 12 parts of glutinous rice noodles, 0.6 parts of Bletilla striata, 1.2 parts of Poria cocos, 4 parts of mugwort leaves, and Goose Bushi Grass 3 servings.

[0044] The preparation method of described water-based environmental protection epoxy anticorrosion pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com