Stable penetration composite rust paint and preparation method thereof

A rust-bearing paint, composite technology, applied in anti-corrosion paint, epoxy resin paint, coating and other directions, can solve the problem of poor rust removal effect, and achieve the effect of small coating performance, good anti-corrosion effect and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

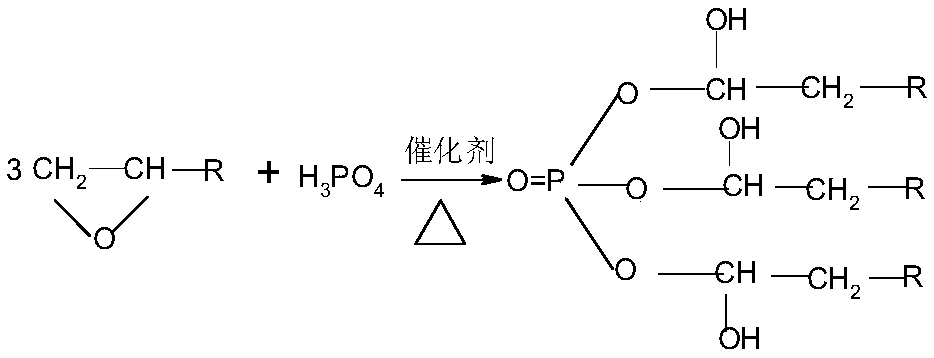

Method used

Image

Examples

Embodiment 1

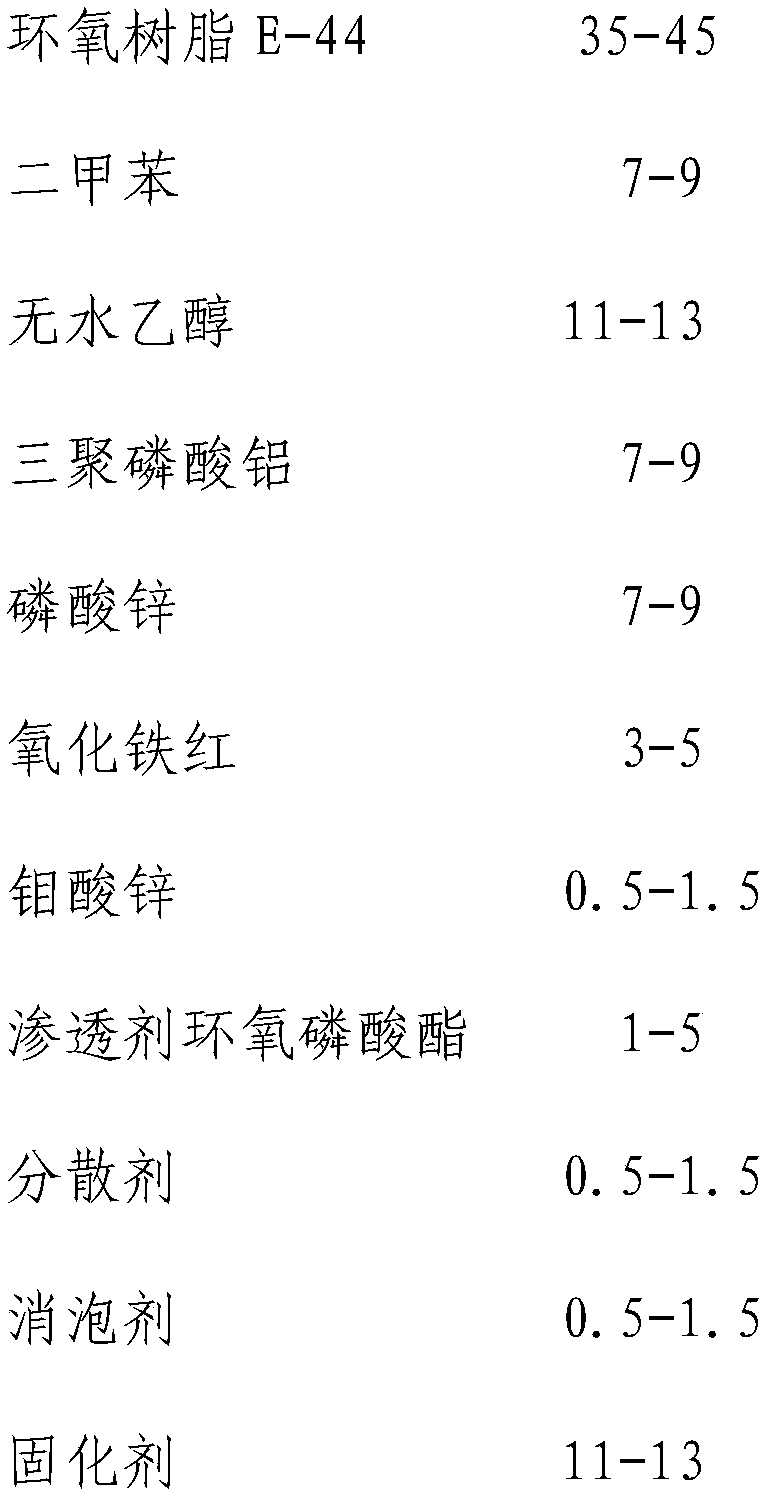

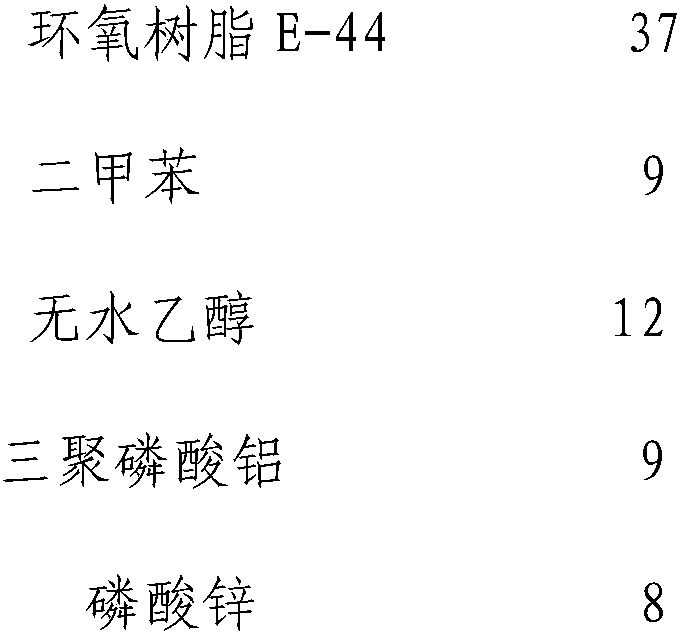

[0037] Each component quality is in the embodiment one:

[0038]

[0039]

[0040] The preparation method is:

[0041] (1) Put epoxy resin E-44 into a container, put it into a water bath and raise the temperature to about 50°C.

[0042] (2) Take out the container and add xylene and use a glass rod for preliminary stirring. After stirring evenly, add absolute ethanol, also use a glass rod for preliminary stirring, and cool to room temperature.

[0043] (3) Weigh aluminum tripolyphosphate and put it into the container after grinding, and use a glass rod for preliminary stirring until the stirring is uniform.

[0044] (4) Weigh the zinc phosphate and grind it into the container, and use a glass rod for preliminary stirring until it is evenly stirred.

[0045] (5) Add iron oxide red to the container after weighing and grinding, and stir evenly with a glass rod.

[0046] (6) Weigh the zinc molybdate and add it into the container, and stir evenly with a glass rod.

[0047]...

Embodiment 2

[0053]

Embodiment 3

[0055]

[0056]

[0057] See Example 1 for the preparation methods of Example 3 and Example 2, which will not be repeated here. The performance parameters of the final prepared coating are: the hardness of the paint film is expressed as 3H in pencil hardness, the adhesion level is 0, and the impact strength According to the GB / T1732-1993 standard test, the drop height of the weight is 50CM, and the paint film has no cracks, wrinkles and peeling off. The salt water resistance test is soaked in 5% NaCl solution for 48 hours at room temperature without foaming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com