Special osmosis primer paint for solid wood furniture

A furniture and solid wood technology, applied in the field of paint and coating, can solve problems such as poor, uneven brushing, collapsed transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

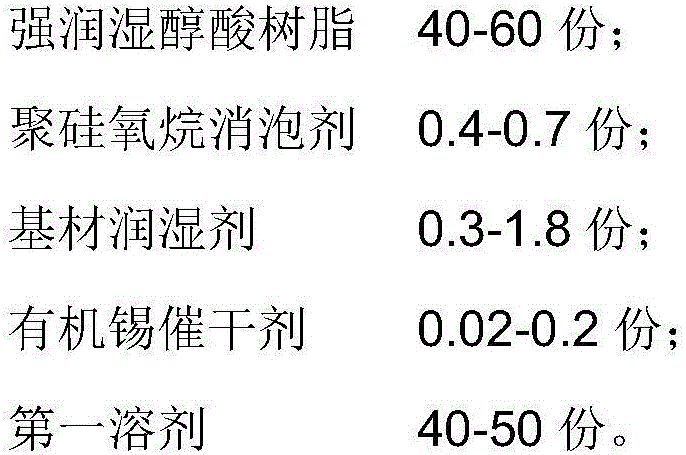

[0032] Solid wood furniture penetrating primer, including: main paint and curing agent, wherein, the main paint includes:

[0033]

[0034] Curing agents include:

[0035] Hexamethylene diisocyanate 41kg;

[0036] Toluene diisocyanate trimer 14kg;

[0037] 40kg of the second solvent.

[0038] Among them, the acid value of the strong wetting alkyd resin is 4±2mgKOH / g, and the viscosity is 4500±1000mPa . s / 25°C, the hydroxyl content is 120-130%, the water content is ≤0.1%, the density is 1.01g / ml / 20°C, and the flash point is about 23°C.

[0039] Wherein, the first solvent is selected from one or more of toluene, xylene, cyclohexanone, propylene glycol methyl ether acetate, and butyl acetate.

[0040] Wherein, the second solvent is selected from one or more of butyl acetate, ethyl acetate, and cyclohexanone.

[0041] A solid wood furniture penetrating primer was prepared according to the above-mentioned components.

Embodiment 2

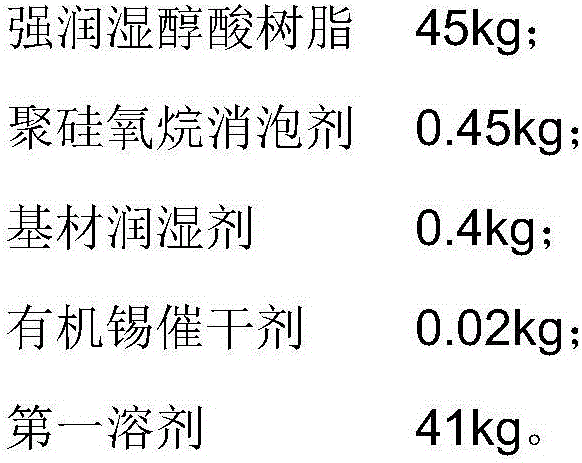

[0043] Solid wood furniture penetrating primer, including: main paint and curing agent, wherein, the main paint includes:

[0044]

[0045] Curing agents include:

[0046] Hexamethylene diisocyanate 42kg;

[0047] Toluene diisocyanate trimer 16kg;

[0048] 41kg of the second solvent.

[0049] Among them, the acid value of the strong wetting alkyd resin is 4±2mgKOH / g, the viscosity is 4500±1000mPa·s\25℃, the hydroxyl content is 120-130%, the moisture content is ≤0.1%, and the density is 1.01g / ml\ 20°C, the flash point is about 23°C.

[0050] Wherein, the first solvent is selected from one or more of toluene, xylene, cyclohexanone, propylene glycol methyl ether acetate, and butyl acetate.

[0051] Wherein, the second solvent is selected from one or more of butyl acetate, ethyl acetate, and cyclohexanone.

[0052] A solid wood furniture penetrating primer was prepared according to the above-mentioned components.

Embodiment 3

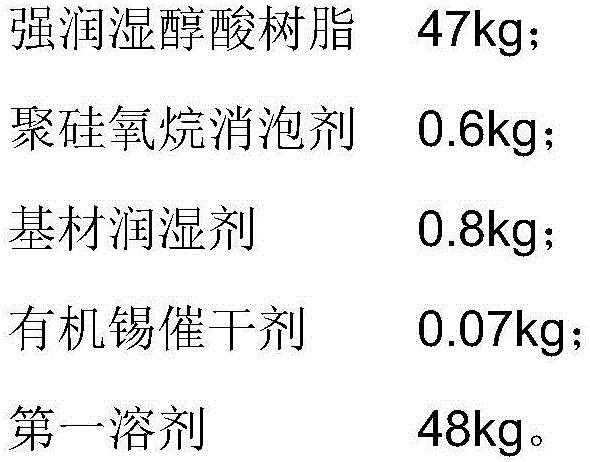

[0054] Solid wood furniture penetrating primer, including: main paint and curing agent, wherein, the main paint includes:

[0055]

[0056] Curing agents include:

[0057] Hexamethylene diisocyanate 43kg;

[0058] Toluene diisocyanate trimer 15kg;

[0059] 41kg of the second solvent.

[0060] Among them, the acid value of the strong wetting alkyd resin is 4±2mgKOH / g, and the viscosity is 4500±1000mPa . s\25℃, the hydroxyl content is 120-130%, the water content is ≤0.1%, the density is 1.01g / ml\20℃, and the flash point is about 23℃.

[0061] Wherein, the first solvent is selected from one or more of toluene, xylene, cyclohexanone, propylene glycol methyl ether acetate, and butyl acetate.

[0062] Wherein, the second solvent is selected from one or more of butyl acetate, ethyl acetate, and cyclohexanone.

[0063] A solid wood furniture penetrating primer was prepared according to the above-mentioned components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com