Preparation process of a radiochromic label dosimeter

A technology of radiation discoloration and preparation technology, which is applied in the field of radiation discoloration label dosimeter and preparation technology, which can solve the problems of inconvenient use, difficult release, low drying temperature, etc., and achieve the goal of broadening the application range, uniform and smooth film formation, and avoiding wrinkles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

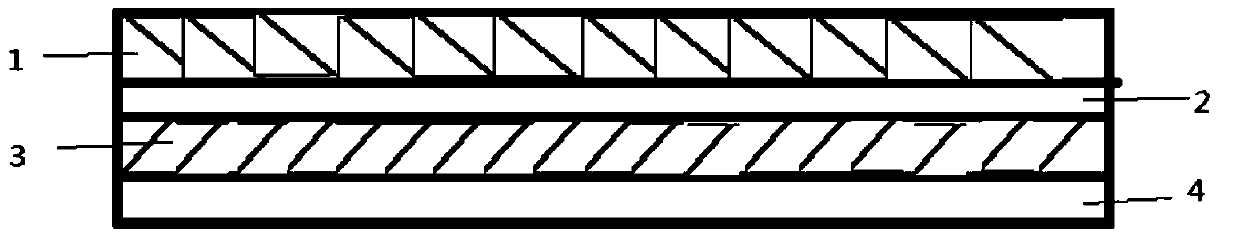

[0039] A radiochromic label dosimeter, the dosimeter comprises a sensitive layer 1, a base layer 2, an adhesive layer 3 and a release paper layer 4 in order from top to bottom; the thickness of the sensitive layer 1 is 75 μm, and the thickness of the base layer 2 The thickness is 50 μm.

[0040] The formula of the sensitive layer 1 includes polymer polyvinyl alcohol, acid-sensitive dye methyl orange, auxiliary color-changing substance chloral hydrate and first solvent water, the weight and number ratio of polymer, acid-sensitive dye, auxiliary color-changing substance, and solvent It is 100:0.2:10:700.

[0041] The formula of the base layer 2 includes a base layer material and a second solvent, wherein the base material is polyacrylate, and the second solvent is ethanol; the ratio of parts by weight of the base material to the solvent is 1:7;

[0042] The adhesive layer 3 and the peeling paper layer 4 are self-adhesive paper, wherein the self-adhesive paper is a double-sided ...

Embodiment 2

[0051] The difference from Example 1 is that the acid-sensitive dye is a mixture of methyl orange and bromocresol green, the ratio of parts by weight is 1:1, and the color of the dosimeter will change from green to red through yellow within a certain radiation dose range .

Embodiment 3

[0053] The difference from Example 1 is that the thickness of the sensitive layer is 50 μm, and the thickness of the base layer is 20 μm.

[0054] In the formula of the sensitive layer, the polymer is 100 parts (parts by weight), the acid-sensitive dye is 0.1 parts (parts by weight), the auxiliary discoloration substance is 5 parts (parts by weight), and the first solvent is 6000 parts (parts by weight). number of parts); the polymer is one of polyvinyl chloride (PVC), polyvinylidene chloride (PVDC), polyvinyl butyral (PVB), polymethyl methacrylate (PMMA), nylon or Various; the acid-sensitive dyes are dimethyl yellow, bromophenol blue, neutral red, alizarin red, crystal violet, bromocresol green, methylene blue, xylenol orange, alizarin, phenolphthalein, thymolphthalein One or more of , methyl violet, malachite green, thymol blue, bromothymol blue, methyl red, Congo red, aniline blue, bromocresol violet, and cresol red; The auxiliary discoloration substance is one or more of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com