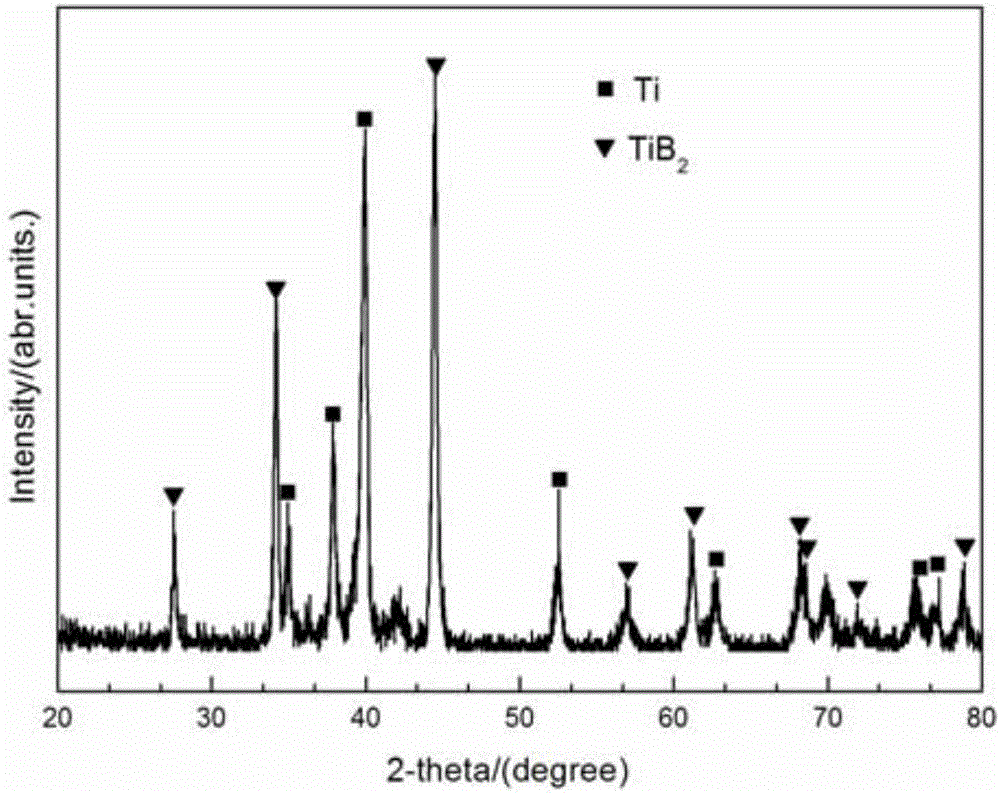

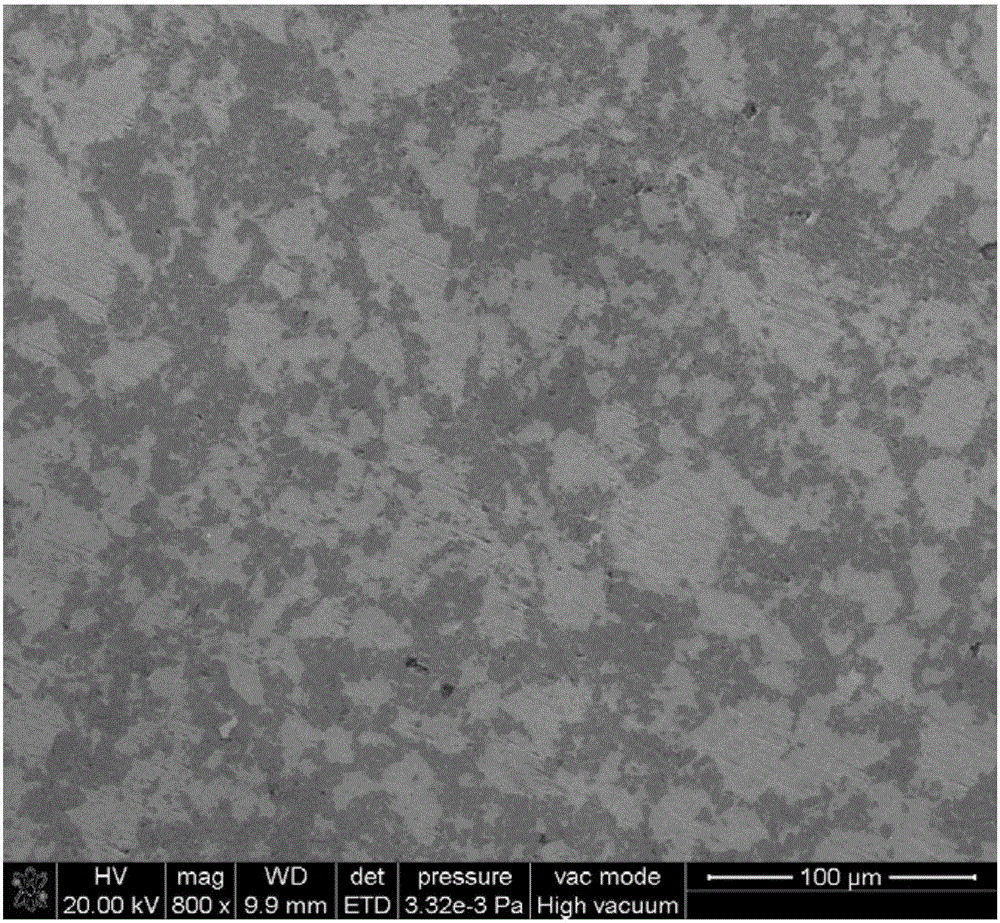

Grid-structure TiB2-Ti composite metal-ceramic material and preparation method thereof

A tib2-ti, composite metal technology, applied in the field of grid structure TiB2-Ti composite cermet material and its preparation, can solve the problems of difficulty in obtaining, corrosion of Ti matrix, slow diffusion rate of active boron atoms, etc. The preparation method is simple and easy to control, and the effect is convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Use a multi-stage strong magnetic field separation cabinet to remove trace iron impurities from the raw Ti powder until no more impurities are separated;

[0023] 2) Weigh 50g of Ti powder (300 mesh) and TiB from which impurities have been removed 2 Flour (600 mesh) 50g is mixed with 30g absolute ethanol (until it can be stirred well but Ti powder and TiB will not appear again) 2 powder layering), and then put the slurry in a star ball mill for 3h to make Ti powder and TiB 2 Powders are uniformly mixed, and then dried under vacuum conditions to obtain pre-alloyed powders;

[0024] 3) Fill the pre-alloyed powder into the carbon mold , put the corresponding carbon material cover on the compacted cover, and then place it in a vacuum furnace for sintering, the sintering temperature is 800°C, and the time is 1.5h;

[0025] 4) Take out the sintered pre-alloyed powder together with the carbon mold and assemble them into the corresponding type of pyrophyllite mold. Use t...

Embodiment 2

[0031] 1) Use a multi-stage strong magnetic field separation cabinet to remove trace iron impurities from the raw Ti powder until no more impurities are separated;

[0032] 2) Weigh 100g of Ti powder (600 mesh) and TiB from which impurities have been removed 2Flour (1000 mesh) 250g is mixed with 150g acetone (until it can be stirred well but Ti powder and TiB will not appear 2 powder layering), and then put the slurry in a star ball mill for 5h to make Ti powder and TiB 2 Powders are uniformly mixed, and then dried under vacuum conditions to obtain pre-alloyed powders;

[0033] 3) Fill the pre-alloyed powder into the carbon mold , put the corresponding carbon material cover on the compacted cover, and then place it in a vacuum furnace for sintering, the sintering temperature is 1000°C, and the time is 3h;

[0034] 4) Take out the sintered pre-alloyed powder together with the carbon mold and assemble them into the corresponding type of pyrophyllite mold. Use the six-sided t...

Embodiment 3

[0036] 1) Use a multi-stage strong magnetic field separation cabinet to remove trace iron impurities from the raw Ti powder until no more impurities are separated;

[0037] 2) Weigh 50g of Ti powder (500 mesh) and TiB from which impurities have been removed 2 Powder (1200 mesh) 35g is slurried with 10g ether and 5g ethylene glycol (until it can be stirred well but no Ti powder and TiB 2 powder layering), and then put the slurry in a star ball mill for 4h to make Ti powder and TiB 2 Powders are uniformly mixed, and then dried under vacuum conditions to obtain pre-alloyed powders;

[0038] 3) Fill the pre-alloyed powder into the carbon mold , put the corresponding carbon material cover on the compacted cover, and then place it in a vacuum furnace for sintering, the sintering temperature is 1100°C, and the time is 1h;

[0039] 4) Take out the sintered pre-alloyed powder together with the carbon mold and assemble them into the corresponding type of pyrophyllite mold. Use the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com