Preparation of PNIPAM-RGO graphene composite material and application thereof on smart response modified electrode

A technology of composite materials and modified electrodes, which is applied in the field of biosensors, can solve the problems of cumbersome synthesis methods and limit the application of complexes, and achieve good electron transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (purification of N-isopropylacrylamide NIPAM)

[0035]Add 10.0020g of NIPAM monomer into a two-necked round-bottomed flask, heat and drop acetone until the NIPAM is completely dissolved, cool to reflux, and add n-hexane dropwise until a white substance appears after adding n-hexane (V acetone: V n-hexane = 1:6 ), stop heating, cool to room temperature, transfer to 0°C for 10 hours, and transfer to -10°C for 20 hours. After the crystals were precipitated, they were taken out for suction filtration and washed with n-hexane. Dry under vacuum at room temperature.

Embodiment 2

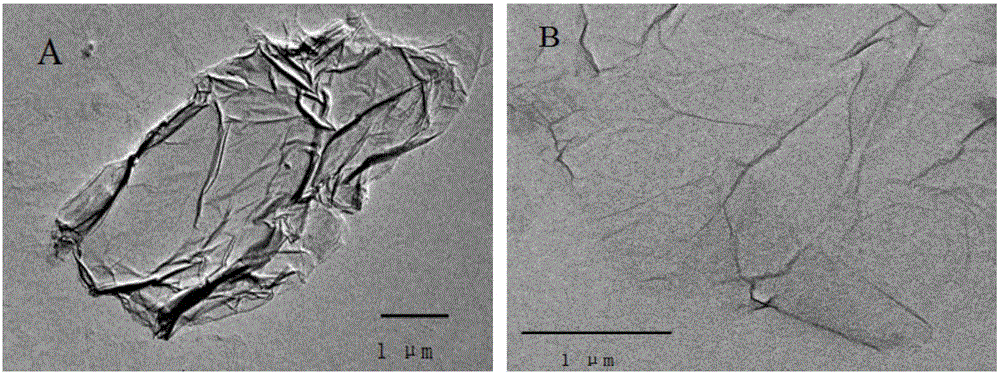

[0036] Embodiment 2 (preparation of graphene oxide)

[0037] Graphene oxide was prepared by the Hummer method. Add 67.5mL of concentrated sulfuric acid to the three-neck round bottom flask, then place it in an ice-water bath, then add 2.0011g of high-purity graphite and 1.6003g of NaNO 3 , after stirring evenly, add 9.0002g of potassium permanganate solid, then react in a water bath between 32-38°C for 30min, then place it at room temperature for 7 days, finally dilute with 560.0mL of hot water, add 3% H 2 o 2 Until the solution is bright yellow, let stand for 1h, centrifuge GO (10000rpm, 10min), wash the GO solution with 0.01M NaOH to neutral, then wash with water to wash off excess SO 4 2- , tested with saturated barium acetate until there is no white precipitate, and finally washed twice with ethanol, and the product was dried in a vacuum oven for later use.

Embodiment 3

[0038] Embodiment 3 (preparation of poly-N-isopropylacrylamide PNIPAM)

[0039] Take 1.0005g of NIPAM, dissolve it in 30.0mL of water, add 17.0mg of azobisisobutylamidine hydrochloride (AIBA), and react at 70°C for 2h to obtain PNIPAM polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com