Device achieving dedusting, desulfuration and denitration by means of acid and alkali potential water

A potential water and denitrification technology, applied in the field of alkaline potential water dust removal, acid use, denitrification devices, and desulfurization, can solve the problems of high initial investment and operating costs, large investment in process equipment, and easy corrosion of equipment, so as to avoid secondary production. The effect of pollution, low travel cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

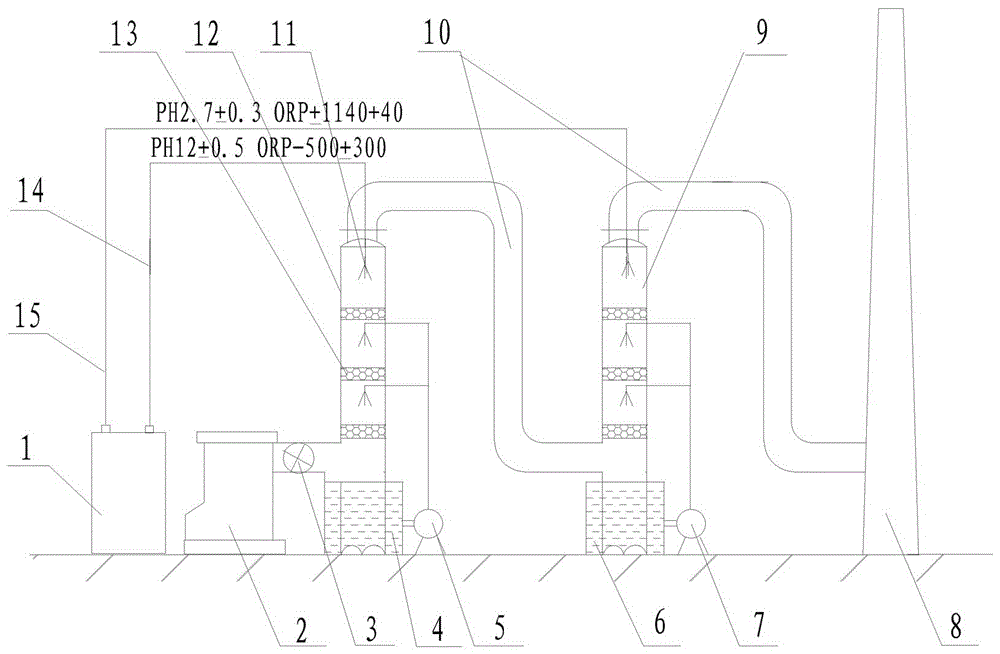

[0011] A device for dust removal, desulfurization and denitrification using acid and alkali potential water, comprising an electrolytic reactor 1, a boiler 2, a chimney 8, a flue gas induced draft fan 3, a flue gas desulfurization sprayer 12, a flue gas denitrification sprayer 9, a desulfurization Circulation pool 4, denitration circulation pool 6, desulfurization circulation pump 5, denitration circulation pump 7. The flue gas desulfurization shower 12 and the flue gas denitration shower 9 are respectively installed in the desulfurization circulation pool 4 and the denitration circulation pool 6 with their bottoms. The electrolytic reactor 1 electrolyzes salt water through a pulse power supply, and membrane electrolysis generates acidic oxidation potential water 15 and alkaline reduction potential water 14, and the alkaline reduction potential water 14 has a pH value of 12±0.5, ORP-500±300 , connected to the top of the flue gas desulfurization sprayer 12 through a water deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com