Production method and use of natural tremella polysaccharide

A technology of Tremella polysaccharide and production method, applied in directions such as pharmaceutical formulations, cosmetic preparations, preparations for skin care, etc., can solve problems such as low preparation amount, low yield, unfavorable industrial production, etc., and achieve high preparation amount and yield High, excellent antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

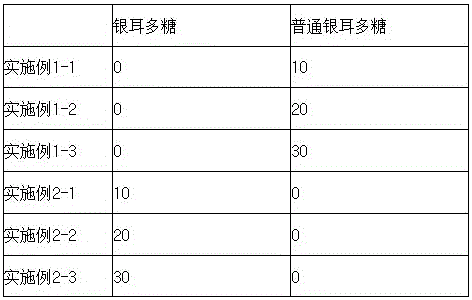

Embodiment 1

[0021] A kind of production method of natural white fungus polysaccharide of the present invention, comprises the following steps:

[0022] (1) select insect-free, nontoxic white fungus dry pulverization for subsequent use;

[0023] (2) Extract with distilled water from a container containing dried white fungus, adjust the pH to above 9.0 with alkali, and extract at room temperature for 24 hours;

[0024] (3) After the extraction is completed, add cationic resin to wash, and adjust the pH to below 7.0;

[0025] (4) Use an ultrafiltration membrane to intercept high molecular weight impurities;

[0026] (5) The filtrate is concentrated to a specific gravity of 1:3 using a single-effect concentrator;

[0027] (6) The concentrated solution is precipitated with ethanol, stirred for 1 hour, and left to stand for 12 hours;

[0028] (7) Use a plate filter press to collect the white solid, which is tremella polysaccharide.

[0029] The alkali used is sodium hydroxide; the mass conc...

Embodiment 2

[0031] A kind of production method of natural white fungus polysaccharide of the present invention, comprises the following steps:

[0032] (1) select insect-free, nontoxic white fungus dry pulverization for subsequent use;

[0033] (2) Extract with distilled water from a container containing dried white fungus, adjust the pH to above 9.0 with alkali, and extract at room temperature for 26 hours;

[0034] (3) After the extraction is completed, add cationic resin to wash, and adjust the pH to below 7.0;

[0035] (4) Use an ultrafiltration membrane to intercept high molecular weight impurities;

[0036] (5) The filtrate is concentrated to a specific gravity of 1:4 using a single-effect concentrator;

[0037] (6) The concentrated solution is precipitated with ethanol, stirred for 1 h, and left to stand for 15 h;

[0038] (7) Use a plate filter press to collect the white solid, which is tremella polysaccharide.

[0039] The alkali used is sodium hydroxide; the mass concentrati...

Embodiment 3

[0041] A kind of production method of natural white fungus polysaccharide of the present invention, comprises the following steps:

[0042] (1) select insect-free, nontoxic white fungus dry pulverization for subsequent use;

[0043] (2) Extract with distilled water from a container containing dried white fungus, adjust the pH to above 9.0 with alkali, and extract at room temperature for 28 hours;

[0044] (3) After the extraction is completed, add cationic resin to wash, and adjust the pH to below 7.0;

[0045] (4) Use an ultrafiltration membrane to intercept high molecular weight impurities;

[0046] (5) The filtrate is concentrated to a specific gravity of 1:5 using a single-effect concentrator;

[0047] (6) The concentrated solution is precipitated with ethanol, stirred for 2 hours, and left to stand for 18 hours;

[0048] (7) Use a plate filter press to collect the white solid, which is tremella polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com