Preparing method for magnesium-containing hydroxyapatite coating on surface of carbon/carbon composite

A technology of magnesium-containing hydroxyapatite and carbon composite materials, which is applied in the direction of metal material coating technology, coating, liquid chemical plating, etc., can solve the problems of limited application and high frequency, and achieve the simple and easy operation of the preparation method, coating Uniform layer and control growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

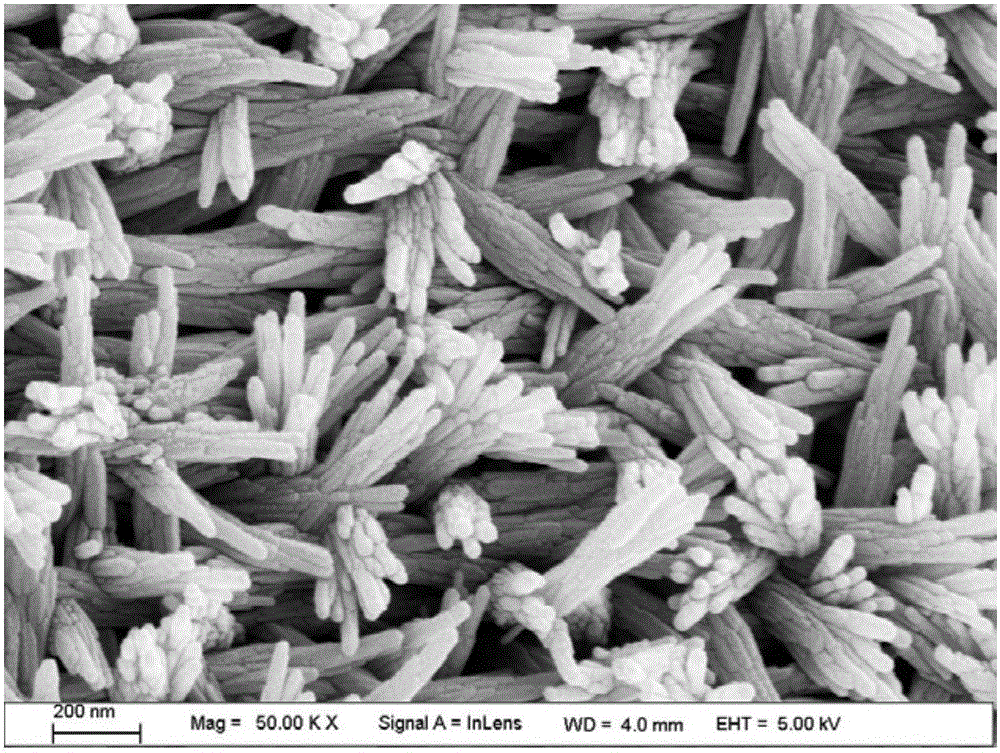

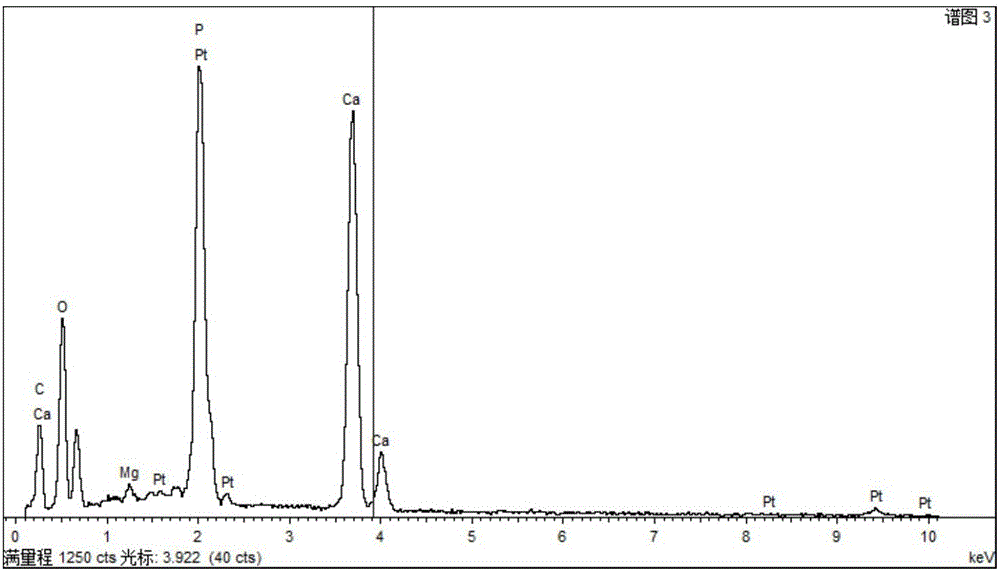

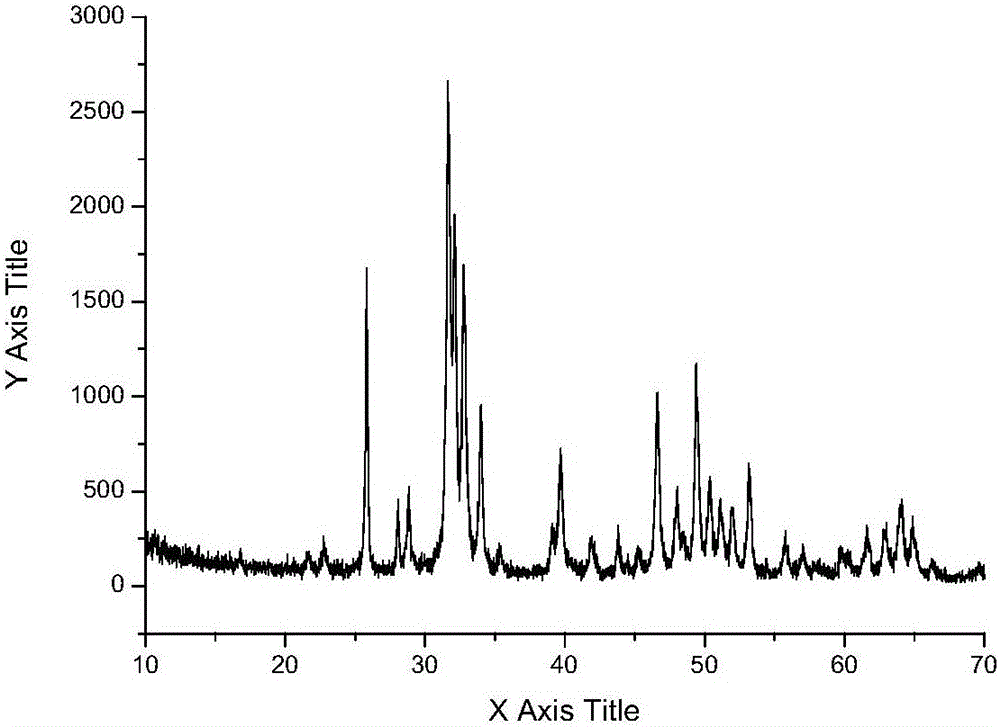

[0027] Set the density to 1.3g / cm 3 The medical carbon / carbon composite material is placed in a 50ml test tube, and the test tube is filled with hydrochloric acid with a concentration of 37.5%, and the test tube is placed in the radiation field. The absorbed dose of cobalt 60 irradiation is 200KGy, and the carbon / carbon composite material is taken out after irradiation. Wash and dry with deionized water; prepare a mixed solution with 0.16mol / L calcium nitrate, 0.02mol / L magnesium nitrate, and 0.1mol / L ammonium dihydrogen phosphate, and place the pretreated medical carbon / carbon composite material in the mixed solution In the solution, a magnesium-doped apatite coating was prepared on its surface by electromagnetic induction, the electromagnetic induction oscillation frequency was 30KHz, the oscillation current was 200A, the deposition time was 10min, and it was cleaned with deionized water; the magnesium-doped apatite coating was The layer is placed in a hydrothermal kettle co...

Embodiment 2

[0029] Set the density to 1.8g / cm 3 The medical carbon / carbon composite material is placed in a 50ml test tube, and the test tube is filled with hydrochloric acid with a concentration of 10%, and the test tube is placed in the radiation field. The absorbed dose of cobalt 60 irradiation is 500KGy, and the carbon / carbon composite material is taken out after irradiation. Wash and dry with deionized water; 0.16mol / L calcium nitrate, 0.1mol / L magnesium nitrate, and 0.1mol / L ammonium dihydrogen phosphate are prepared as a mixed solution, and the pretreated medical carbon / carbon composite material is placed in the mixed solution. In the solution, a magnesium-doped apatite coating was prepared on its surface by electromagnetic induction, the electromagnetic induction oscillation frequency was 150KHz, the oscillation current was 700A, the deposition time was 8h, and it was cleaned with deionized water; the magnesium-doped apatite coating was The layer is placed in a hydrothermal kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com