Flue gas waste heat recovery and flue gas processing system based on organic Rankine cycle

A flue gas treatment system, Rankine cycle technology, applied in mechanical equipment, steam engine installations, climate sustainability, etc., can solve the problem of small demand for hot and cold users, increased complexity of steam turbine systems, and small heat exchange temperature difference and other issues, to achieve the effect of improving efficiency and energy utilization, being conducive to environmental protection, and promoting energy conservation and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. In this embodiment, calculation analysis is performed in conjunction with data, but the protection scope of the present invention is not limited to the following embodiments.

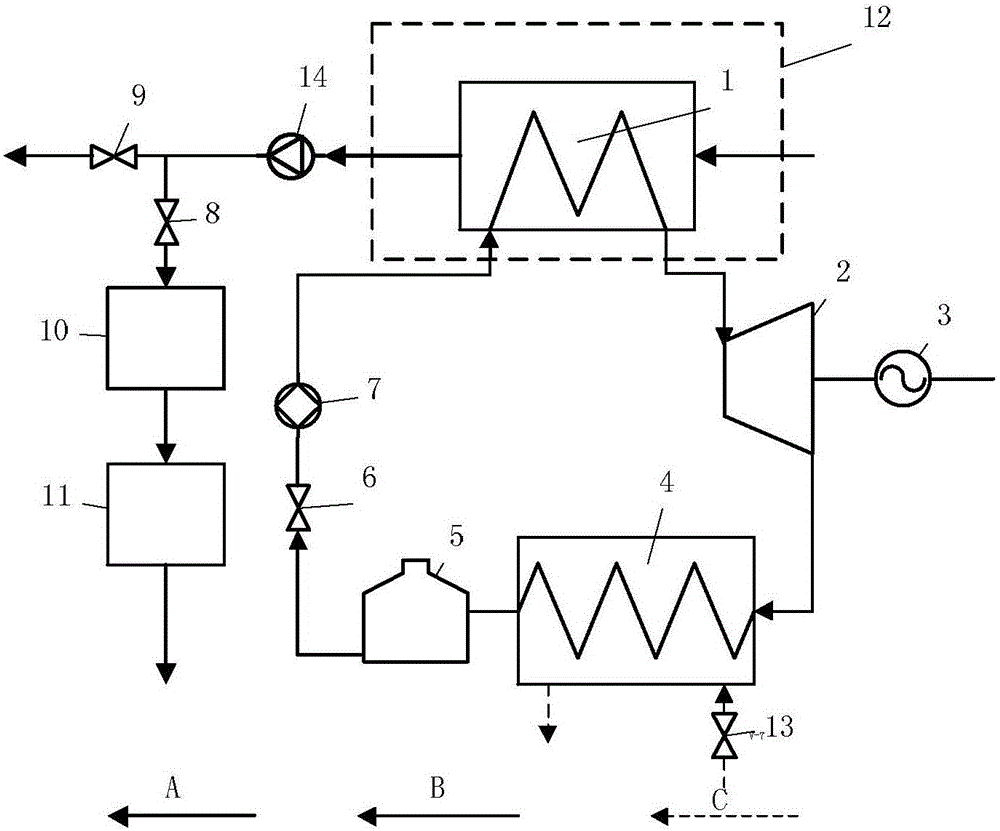

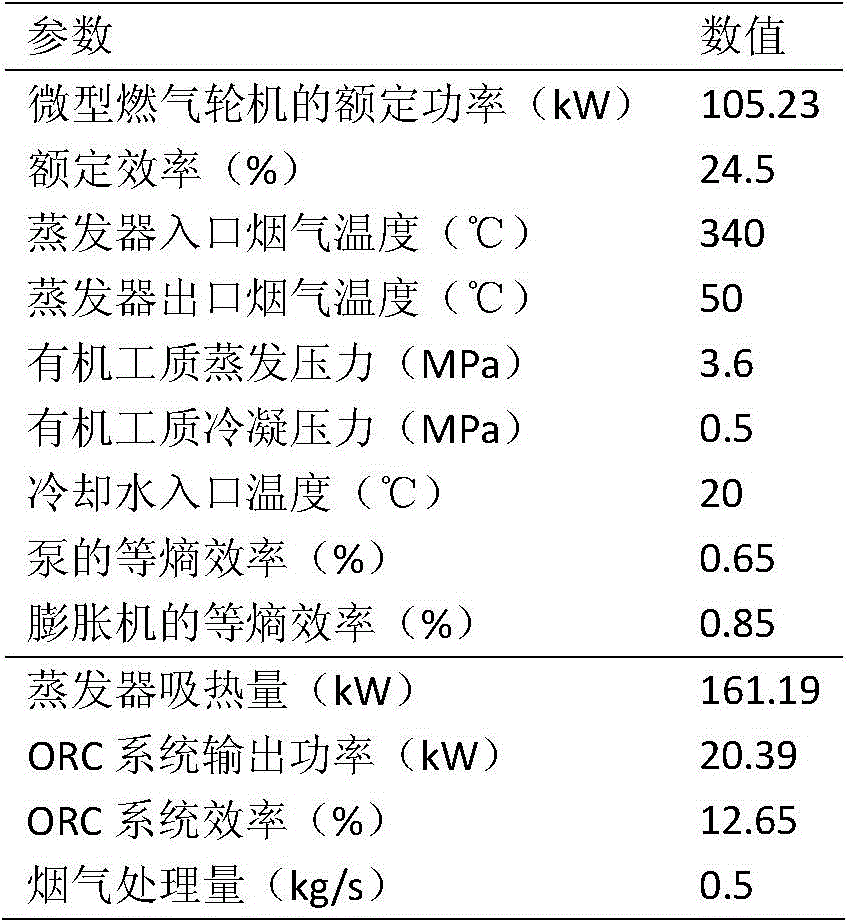

[0027] The flue gas waste heat recovery and treatment system based on the organic Rankine cycle of the present embodiment is as follows: figure 1 As shown in the figure, the system is composed as follows: the evaporator 1 is installed in the flue 12 at the tail of the furnace, so that the flue gas at the tail of the boiler passes through the evaporator 1, the dust collector 10 and the harmful gas removal device 11 successively for heat release, dust removal and absorption of harmful gases. After that, it is discharged into the atmosphere; the evaporator 1, the expander 2, the condenser 4, the liquid storage tank 5, the organic working fluid control valve 6 and the working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com