Odor treatment device of sludge drying system

A sludge drying and treatment device technology, applied in water/sludge/sewage treatment, gas treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of ineffective deodorization and low deodorization efficiency , not suitable for long-term use, etc., to achieve high deodorization efficiency, avoid excessive odor concentration, and improve deodorization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

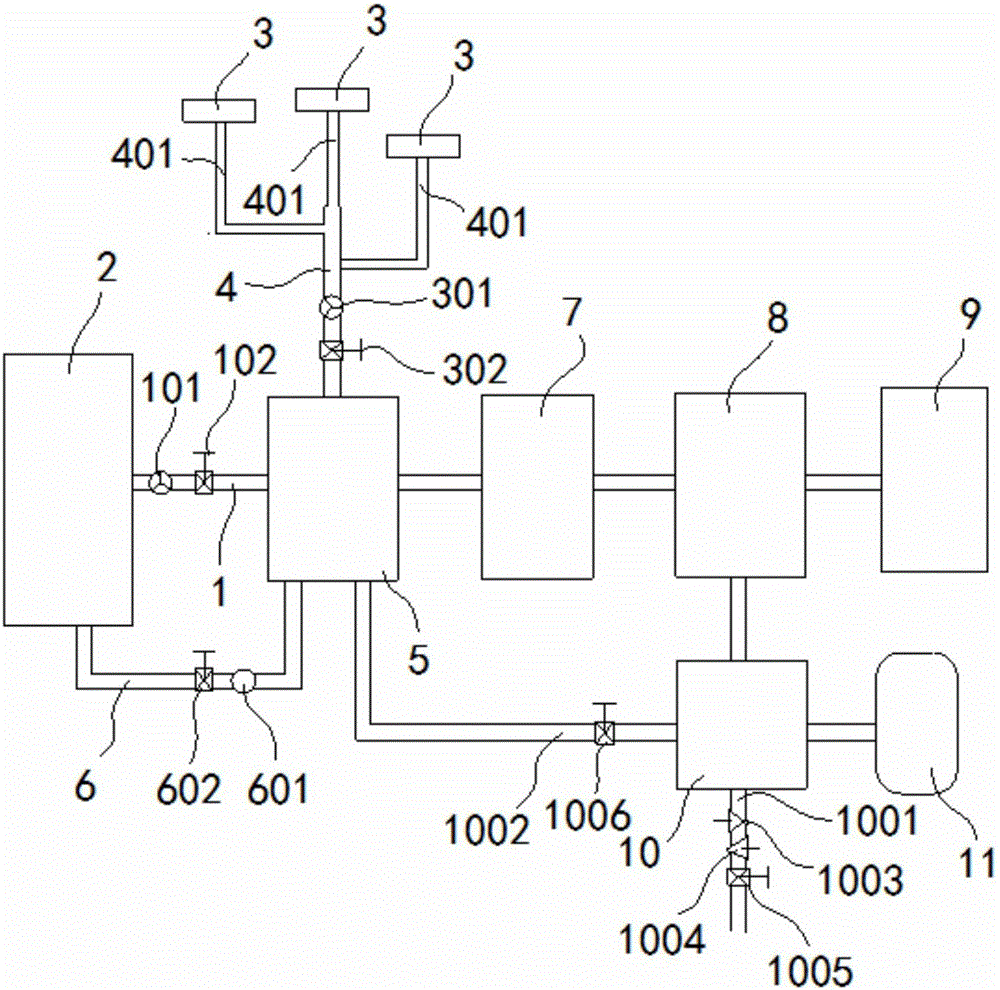

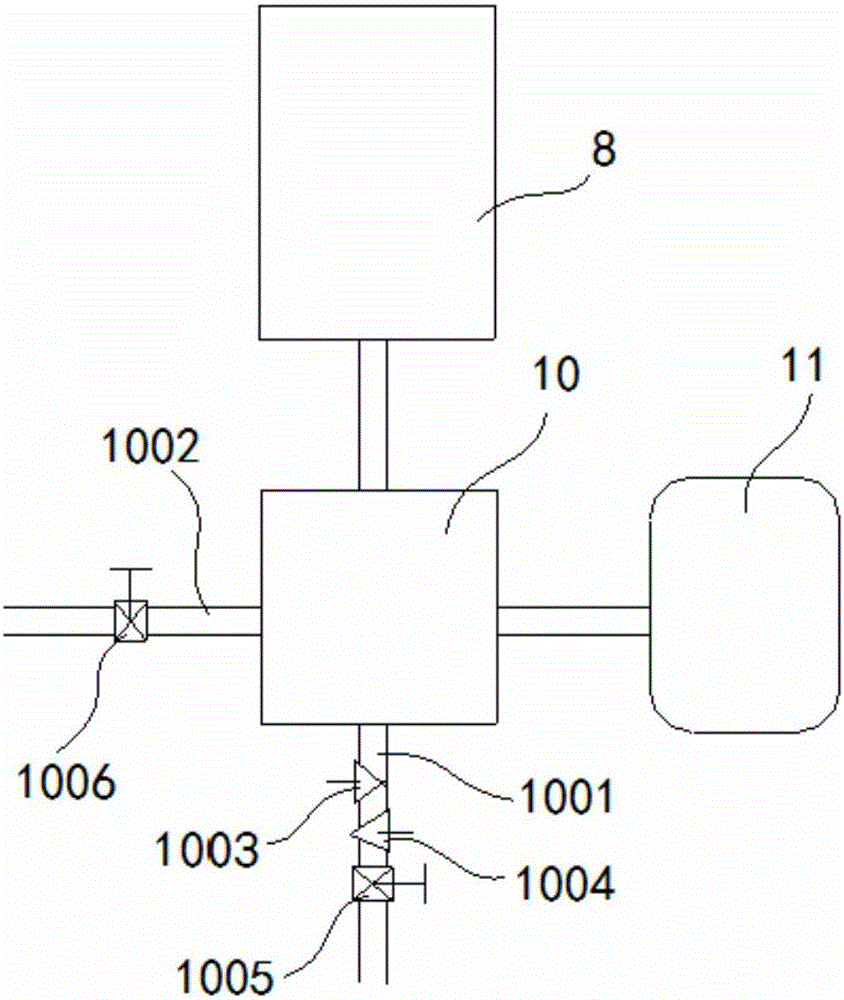

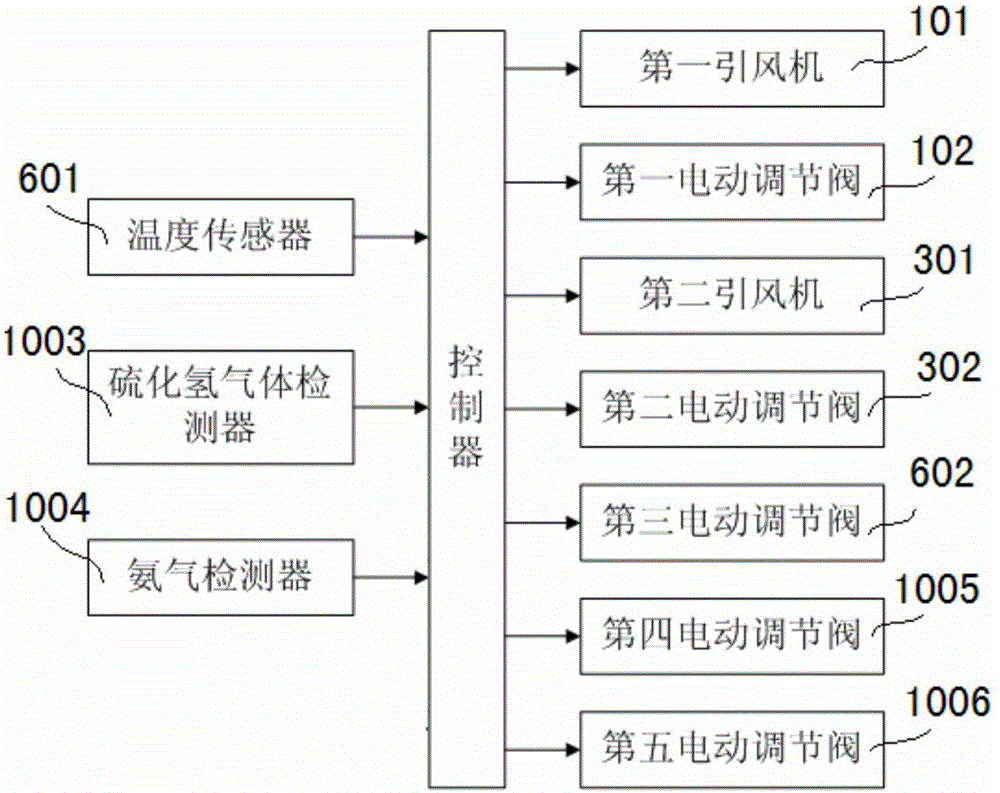

[0029] Such as figure 1 As shown, the odor treatment device of the sludge drying system of the present invention includes:

[0030] A first exhaust pipe 1 , the first end of the first exhaust pipe 1 is connected to a drying chamber 2 . The first exhaust pipe 1 is provided with a first induced draft fan 101 and a first electric regulating valve 102 .

[0031] There are multiple air-introducing outlets 3, and the multiple air-introducing outlets 3 are arranged above the sludge drying workshop.

[0032] The second exhaust pipe 4 is respectively connected to the plurality of air introduction ports 3 through pipe branches 401 . The second exhaust pipe 3 is provided with a second induced draft fan 301 and a second electric regulating valve 302 .

[0033] Combustion chamber 5 , the intake end of the combustion chamber 5 is respectively connected with the first exhaust pipe 1 and the second exhaust pipe 4 .

[0034] A hot gas recovery pipeline 6 , the inlet end of the hot gas reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com