Intelligent constructional mineral type insulation copper sheath flexible fireproof cable and manufacturing method

A technology for intelligent buildings and fireproof cables, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of limited cable manufacturing length, unstable electrical performance, and inconvenient installation and construction, and achieve good cooling and heat insulation protection Function, solve the effect of unstable fire resistance, easy laying and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

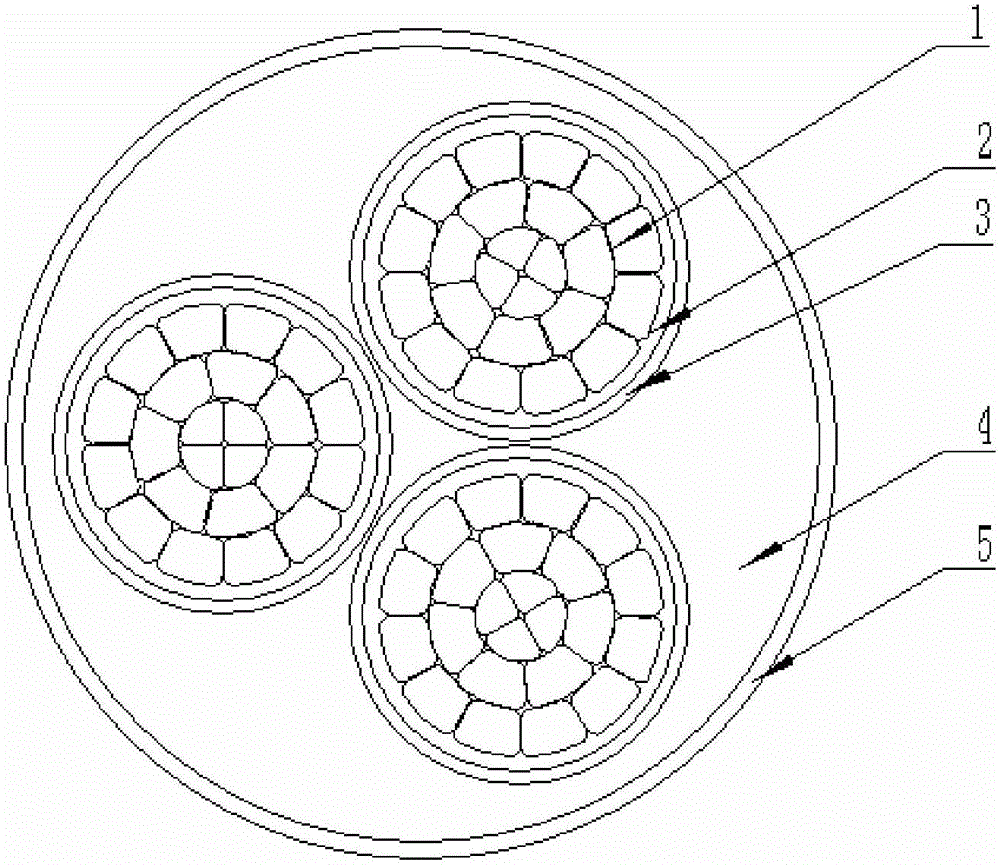

[0028] See figure 1 , the mineral-based insulated copper sheathed flexible fireproof cable for intelligent buildings in this embodiment includes at least one insulated wire core from the inside to the outside, a heat-insulating filling inner sheath 4 and an outer sheath 5; To the outside are the conductor core 1, the refractory insulating layer 2 and the copper protective layer 3; the copper protective layer 3 is a closed and seamless copper or copper alloy tube; the heat-insulating filling inner protective layer 4 is an inorganic mineral material and then wrapped with ore Material fire barriers, or extruded mineral-filled inner sheathing materials. The refractory insulating layer 2 is a wrapped mineral insulating composite tape or an extruded mineral insulating tape, and the thickness of the refractory insulating layer 2 is 0.5-3.0 mm. The conductor core 1 is formed by twisting a single annealed copper single wire or multiple annealed copper single wires, and the middle anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com