Multi-zone reactor for continuous polymerization of alpha-olefin monomers

An olefin monomer and reactor technology, applied in the field of multi-section reactors, can solve the problems of not allowing a large amount of liquid to recycle fluid, heat removal limitation, fluidized bed instability, etc., to improve operability and/or or continuity, eliminating the presence of stagnant sections, reducing the amount of fines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0173] A computer-based mathematical model capable of generating mass and heat balance along the fluidized bed reactor was used to run the simulations operating in dry and condensing modes. First, the model was validated by running it with actual data from commercial polyethylene production. The results are shown in Table 1.

[0174]

[0175] As can be seen from Table 1, the actual data are very comparable to the data from the model.

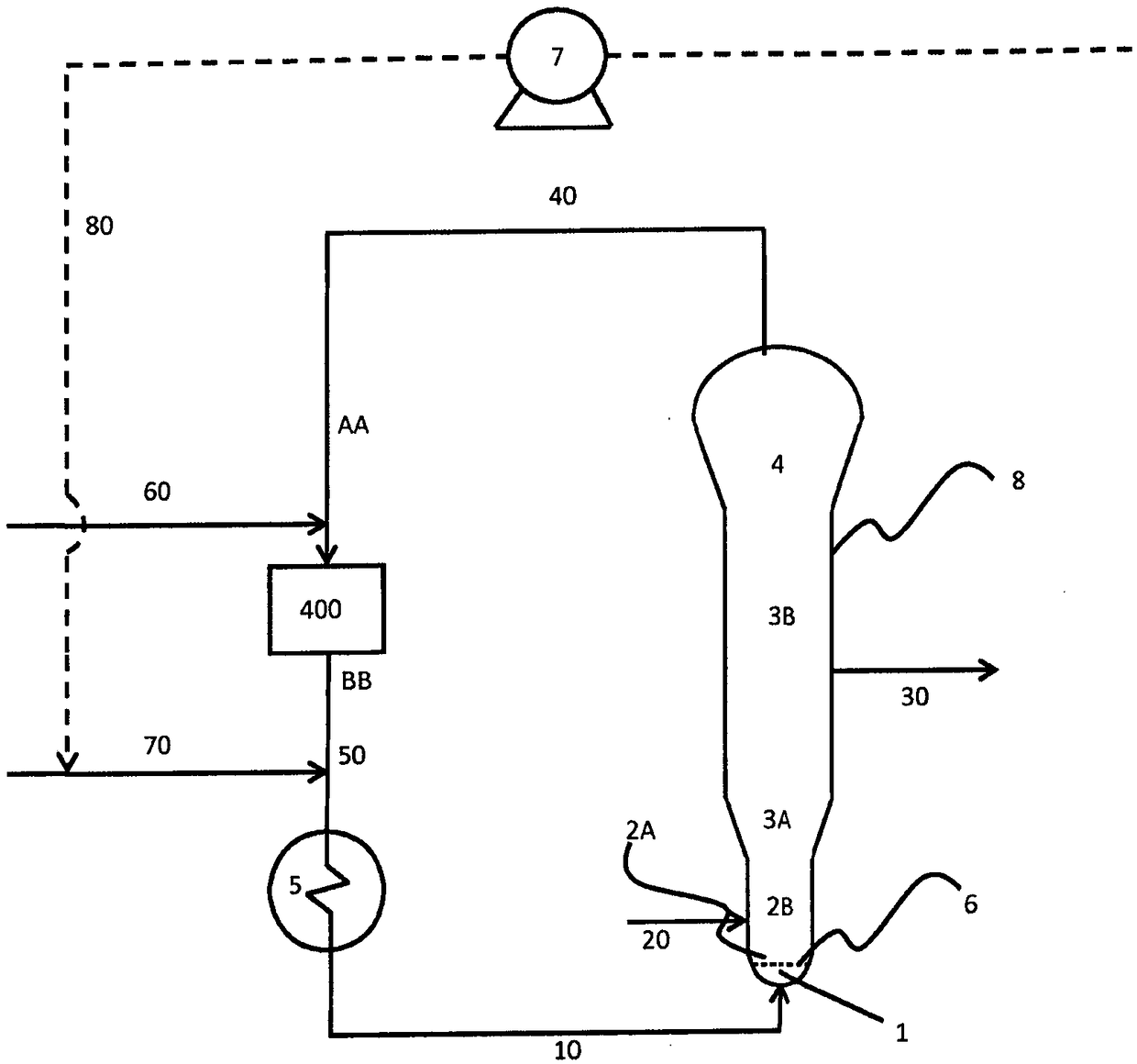

[0176] Subsequently, the polymerization process in a multi-zone reactor was used to carry out the polymerization of ethylene and 1-butene in condensation mode. The model was first run in condensation mode using actual data from commercial polyethylene production to produce a 1-butene / ethylene copolymer with a density of 918 kg / m 3 and a melt flow index of 1.0 (according to Example 6.2 of Turkistani US Patent 6,759,489 B1). Subsequently, the model was re-run according to the invention (scenario 1, 2 and 3).

[0177] The results are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com