Edible plasma protein powder preparing method

A technology of plasma protein powder and blood plasma, which is applied in the field of preparation of edible plasma protein powder, can solve the problems of not meeting the food production conditions and the inability to ensure the hygiene and safety of raw materials in production connection, and achieve the guarantee of biological safety, good gelation, and process Simple and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

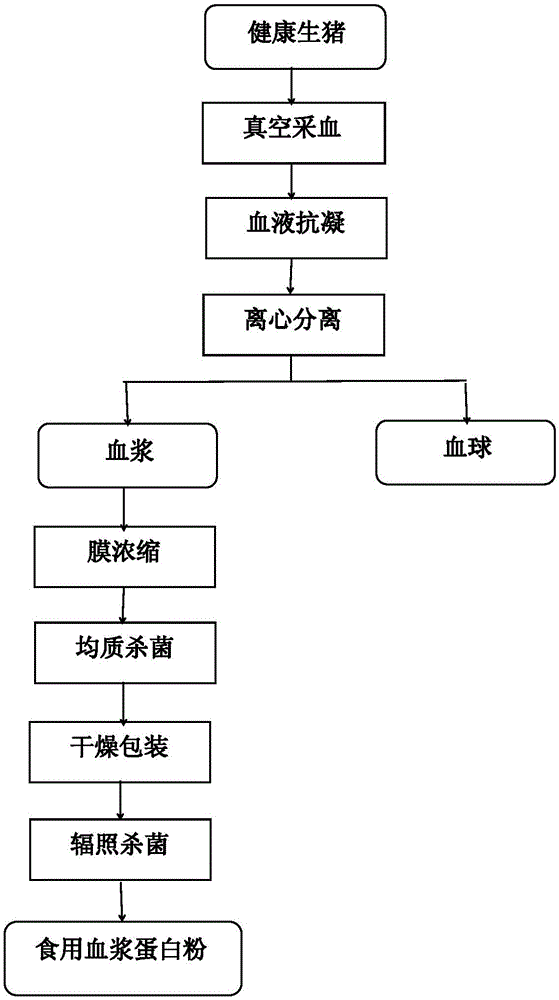

[0032] Preparation of Edible Plasma Protein Powder

[0033] A preparation method for edible plasma protein powder, comprising the steps of:

[0034] (a) Health quarantine: quarantine the pigs that need to be slaughtered, and only after passing the quarantine can they enter the slaughter sequence;

[0035] (b) Vacuum blood collection: use vacuum blood collection equipment to collect blood from livestock and poultry, and collect pig blood into a closed and clean storage tank;

[0036] (c) Blood anticoagulation: add sodium citrate to pig blood, and store it at a temperature of 0-4°C; the quality of sodium citrate added is 5‰ of the quality of pig blood;

[0037] (d) Centrifugal separation: the centrifuge centrifuges at a high speed, and the centrifugal speed is 16500rpm. After centrifugation, the clear liquid is taken as plasma and enters the storage tank;

[0038] (e) Membrane concentration: use membrane filtration equipment to concentrate and enrich the plasma liquid to obtai...

Embodiment 2

[0048] A preparation method for edible plasma protein powder, comprising the steps of:

[0049] (a) Health quarantine: quarantine the pigs that need to be slaughtered, and only after passing the quarantine can they enter the slaughter sequence;

[0050] (b) Vacuum blood collection: use vacuum blood collection equipment to collect blood from livestock and poultry, and collect pig blood into a closed and clean storage tank;

[0051] (c) Blood anticoagulation: add sodium citrate and potassium oxalate in a mass ratio of 1:1 to pig blood, and store at a temperature of 0-4°C; 6‰;

[0052] (d) centrifugation: high-speed centrifugation in a centrifuge, the centrifugation speed is 1400rpm, after centrifugation, the clear liquid is taken as plasma and enters the storage tank;

[0053] (e) Concentration and enrichment: Concentrate and enrich the plasma liquid by using membrane filtration equipment to obtain concentrated plasma liquid; wherein, the pore size of the membrane filtration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com