Amaranthus hypochondriacus recombinant rice and production method thereof

A production method and technology of recombined rice, applied in food ingredients as taste improvers, functions of food ingredients, food drying, etc., can solve problems such as increasing production costs, and achieve low production costs, less cracked grains, and uniform water loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

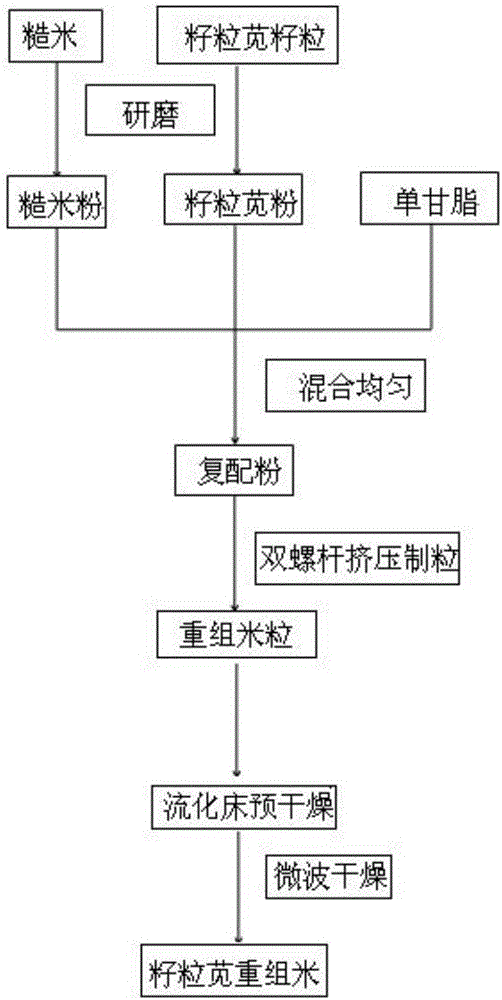

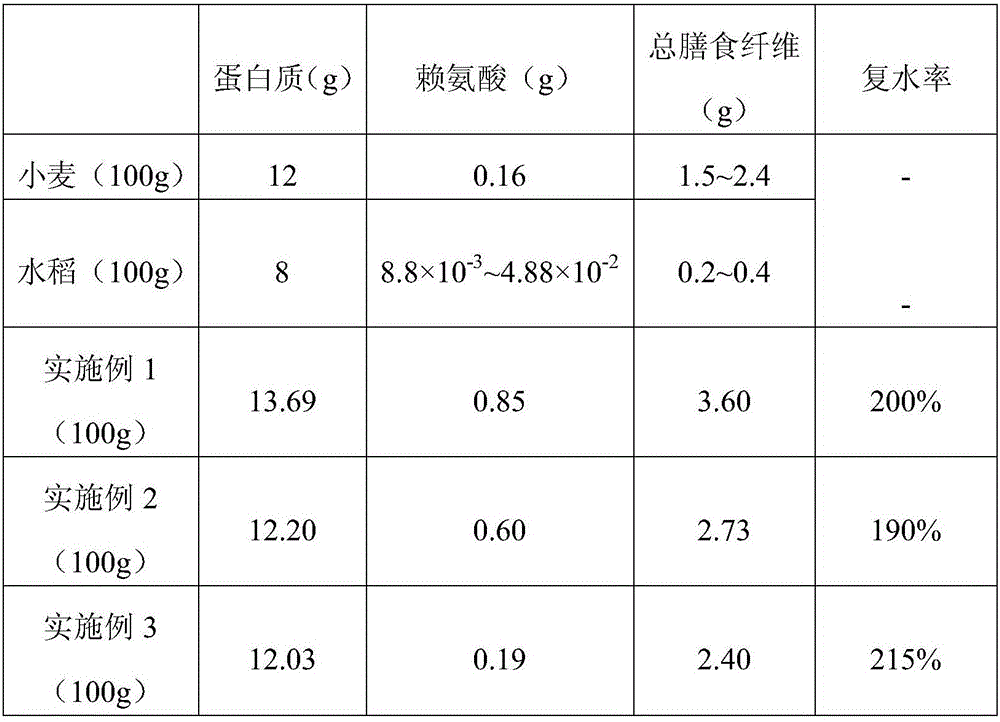

[0030] combine figure 1 It can be seen that brown rice and grain amaranth grains are ground by vertical cyclone mill to obtain brown rice flour and grain amaranth powder respectively, and the gained brown rice flour and grain amaranth powder are passed through a 100 mesh sieve respectively, and 60.5 g of sieved brown rice flour and 39.1 g of sifted brown rice powder are taken. After the sieved grain amaranth powder is mixed evenly, add 0.4g monoglyceride as a modifier, mix evenly to obtain 100g compound powder, send the compound powder into the hopper of a twin-screw extruder, and extrude and cut For granulation, the production process parameters of controlled twin-screw extrusion are: solid feed rate 10kg / h, liquid feed rate 19.5%, and barrel temperature of 40-160°C (the temperatures of the five temperature zones are respectively T1: 70°C, T2: 140°C, T3: 150°C; T4: 80°C; T5: 60°C), the screw speed is 120r / min, the cutting machine speed is 800r / min; the prepared rice grains ar...

Embodiment 2

[0032] Brown rice and grain amaranth grains are ground respectively by vertical cyclone mill to obtain brown rice flour and grain amaranth powder, and the gained brown rice flour and grain amaranth powder pass through a 100 mesh sieve respectively, and 85 g of sieved brown rice flour and 14.5 g of sieved After the grain amaranth powder is mixed evenly, add 0.5g of monoglyceride as an improver, mix evenly to obtain 100g of compound powder, send the compound powder into the hopper of a twin-screw extruder, extrude, cut and granulate, Among them, the control parameters of the twin-screw extrusion production process are: solid feed rate 12kg / h, liquid feed rate 20.5%, and barrel temperature of 40-160°C (the temperatures of the five temperature zones are respectively T1: 65°C, T2: 135°C, T3: 145°C; T4: 75°C; T5: 55°C), the screw speed is 140r / min, the cutting machine speed is 1000r / min; the prepared rice grains are transported to the fluidized bed through the connecting pipe by the ...

Embodiment 3

[0034] Brown rice and grain amaranth grains are ground respectively by vertical cyclone mill to obtain brown rice flour and grain amaranth powder, and the gained brown rice flour and grain amaranth powder pass through a 100 mesh sieve respectively, and 95 g of sieved brown rice flour and 4.7 g of sieved After the grain amaranth powder is mixed evenly, add 0.3g of monoglyceride as an improver, mix evenly to obtain 100g of compound powder, send the compound powder into the hopper of a twin-screw extruder, extrude, cut and granulate, Among them, the control parameters of the twin-screw extrusion production process are: solid feed rate 16kg / h, liquid feed rate 22.0%, barrel temperature 40-160°C (the temperatures of the five temperature zones are respectively T1: 72°C, T2: 145°C, T3: 150°C; T4: 78°C; T5: 57.5°C), the screw speed is 160r / min, the cutting machine speed is 1300r / min; the prepared rice grains are transported to the fluidized bed through the connecting pipe by the fan ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com