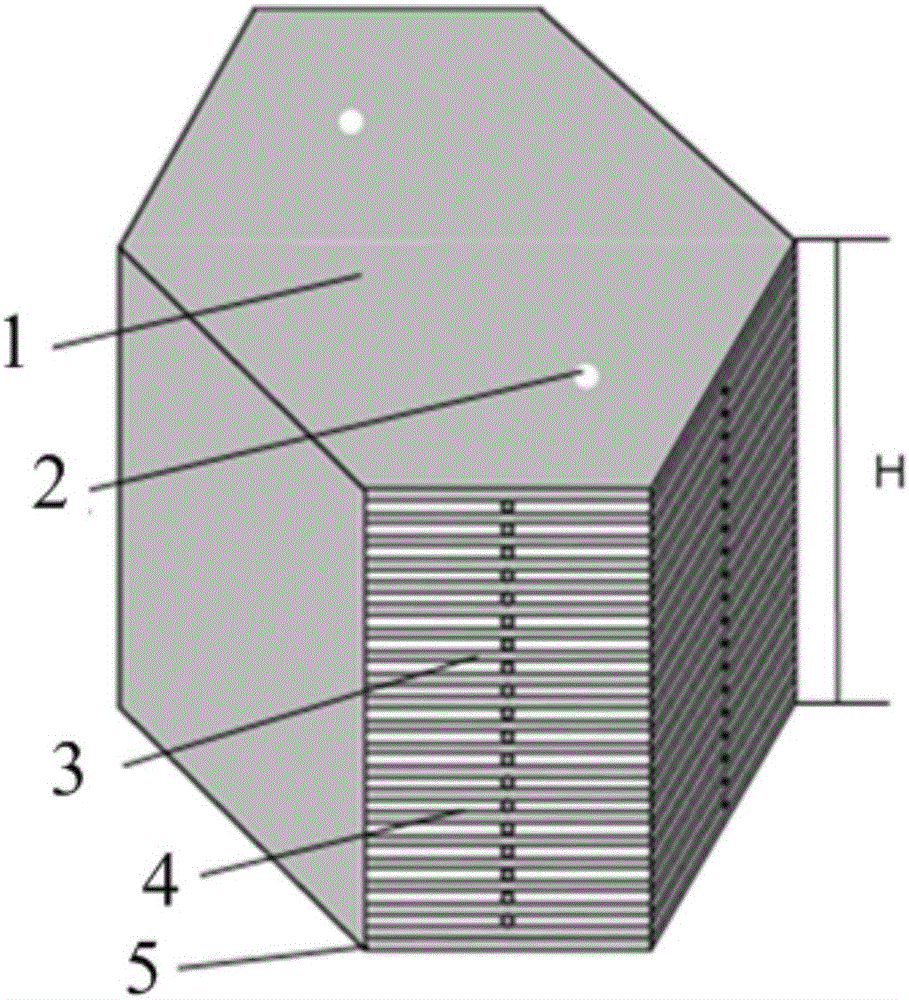

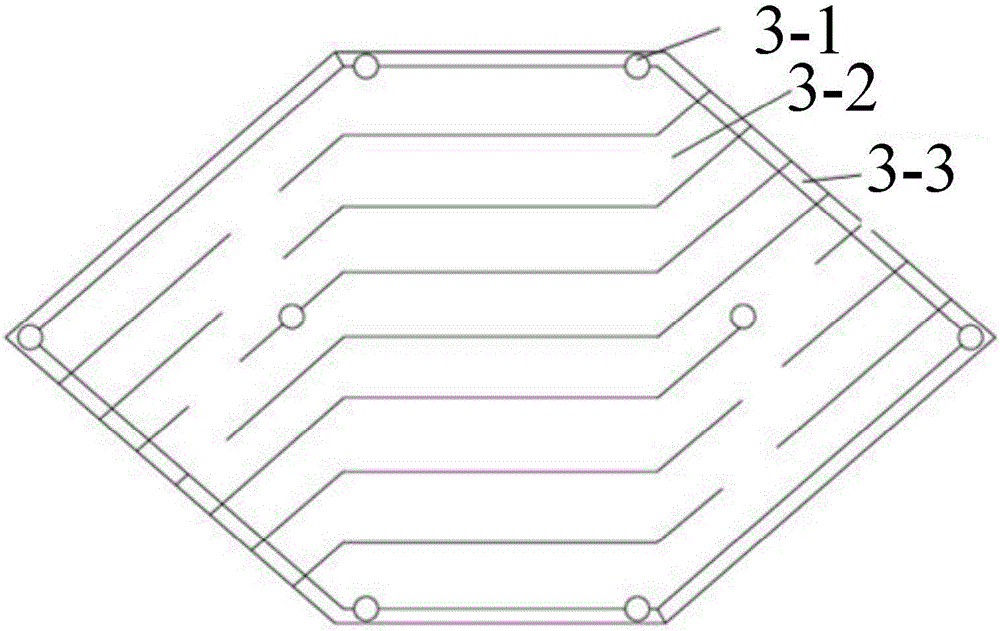

Washable heat exchange membrane, core with washable heat exchange membrane and preparation method for washable heat exchange membrane

A technology of heat exchange membrane and core, which is applied in the field of preparation of washable heat recovery membrane and core, which can solve the problems of non-cleanable, easy to mold, non-reusable, etc., and achieve the effect of cost saving and excellent heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Dissolve 10g of polyvinyl alcohol (PVA) in 90g of deionized water, heat and stir at 90°C until a transparent and homogeneous solution is formed.

[0041] (2) Mix the PVA aqueous solution in step (1) with 12.5g polydimethyldiallylpropyl ammonium chloride (PDDA) aqueous solution (20wt%), 12.5g sulfonated polyetheretherketone (SPEEK) aqueous solution (20wt%) %) at 27°C and stirred to form a homogeneous transparent solution.

[0042] (3) Cast the mixed solution in step (2) on polyester non-woven fabric, and dry naturally to form a film to obtain a PVA / PDDA / SPEEK blended film.

[0043] (4) Immerse the blended film in step (3) in 10% glutaraldehyde aqueous solution, and add a small amount of sulfuric acid, take it out after cross-linking at room temperature for 1 h, rinse with deionized water and dry to obtain cross-linked PVA / PDDA / SPEEK ion total heat exchange membrane. The heat exchange membrane has a thickness of 10-100 μm, including a support layer and a functional...

Embodiment 2

[0046] 1) Dissolve 6g of cellulose acetate (CA) in 94g of acetic acid, heat and stir at 50°C until a transparent and homogeneous solution is formed.

[0047] (2) Mix the CA acetic acid solution in step (1) with 15 g polymethacryloxyethyltrimethylammonium chloride (PTMAC) aqueous solution (20 wt %) at 27° C., and stir to form a homogeneous transparent solution.

[0048] (3) Cast the mixed solution in step (2) on a polypropylene non-woven fabric, and dry naturally to form a film to obtain a CA / PTMAC blended film.

[0049] (4) Immerse the blended membrane in step (3) in 10% maleic anhydride aqueous solution, and add a small amount of sulfuric acid, take it out after crosslinking at room temperature for 1.5h, rinse with deionized water and dry to obtain crosslinked CA / PTMAC ion total heat exchange membrane. The heat exchange membrane has a thickness of 10-100 μm, including a support layer and a functional layer with a thickness of 1-20 μm compounded on the surface of the support la...

Embodiment 3

[0052] (1) Dissolve 10g of polyacrylamide (PAM) in 90g of water, heat and stir at 30°C until a transparent and homogeneous solution is formed.

[0053] (2) Casting the PAM solution in the step (1) on the cellulose non-woven fabric, drying naturally to form a film to obtain a PAM homogeneous film.

[0054] (3) Immerse the PAM homogeneous membrane in step (2) in 5% sodium polyphosphate (SPP) aqueous solution, take it out after cross-linking at room temperature for 0.5h, rinse with deionized water and dry to obtain cross-linked PAM / SPP ion total heat exchange membrane. The heat exchange membrane has a thickness of 10-100 μm, including a support layer and a functional layer with a thickness of 1-20 μm compounded on the surface of the support layer; The mass ratio of high molecular polymer and modifier is 50-99.9:0.1-50.

[0055] The total heat exchange membrane is made into a total heat exchange core. After testing, the total heat exchange film prepared in this example has a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com