Aluminum modified Fe3O4 magnetic material and preparing method and application thereof

A magnetic material and aluminum modification technology, which is applied in the field of aluminum modified Fe3O4 magnetic catalyst and its preparation, can solve the problems of poor reusability and low catalyst activity, and achieve good reusability, high catalytic activity and easy magnetic separation and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of aluminum modified Fe 3 o 4 Magnetic material, its preparation method comprises the following steps:

[0036] Add 3.601g NaOAc to the solution containing 3.703g FeCl 3 ·6H 2O in ethylene glycol (the volume of ethylene glycol is 9mL) solution, stir evenly to obtain a mixed solution; then 2mL aluminum isopropoxide solution (a saturated isopropanol solution of aluminum isopropoxide, wherein The content is 0.133g) into the mixed solution, stirred evenly to obtain the reaction solution; the reaction solution was heated to 198°C for 24 hours at a constant temperature, annealed and cooled, and the obtained solid particles were collected by magnetic separation, and finally washed and dried to obtain the aluminum alloy Sex Fe 3 o 4 Magnetic material (denoted as Fe 3 o 4 -AIP-1).

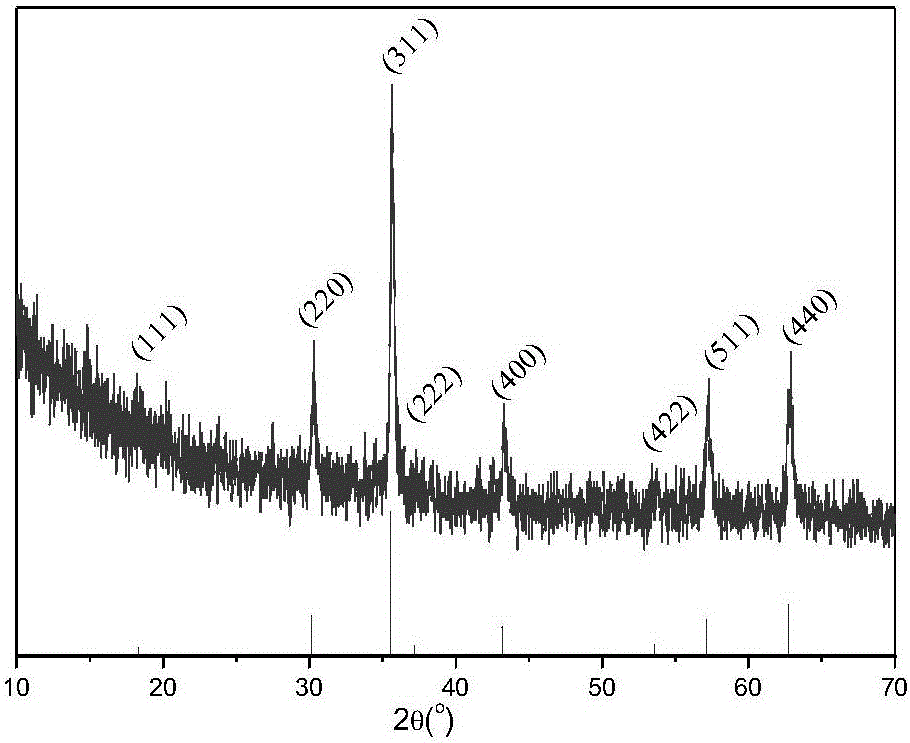

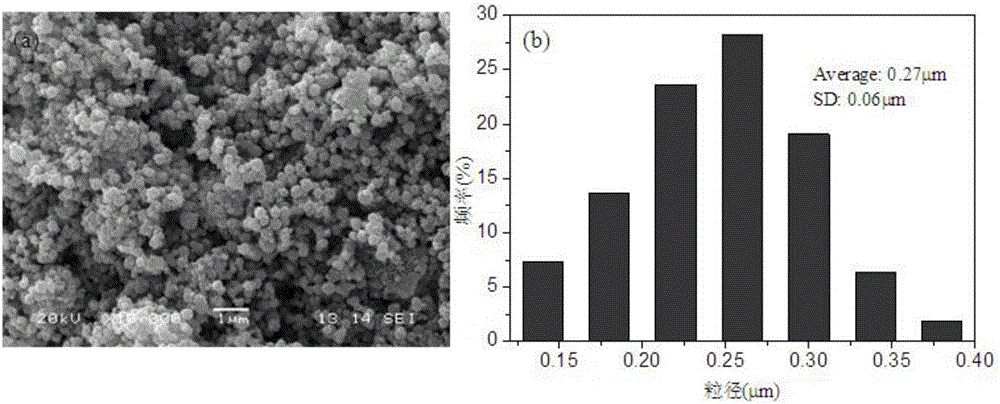

[0037] The X-ray diffraction analysis result of the product obtained in this embodiment is shown in figure 1 , the characteristic peaks in the figure are related to Fe 3 o 4 It is c...

Embodiment 2

[0042] A kind of aluminum modified Fe 3 o 4 Magnetic material, its preparation method comprises the following steps:

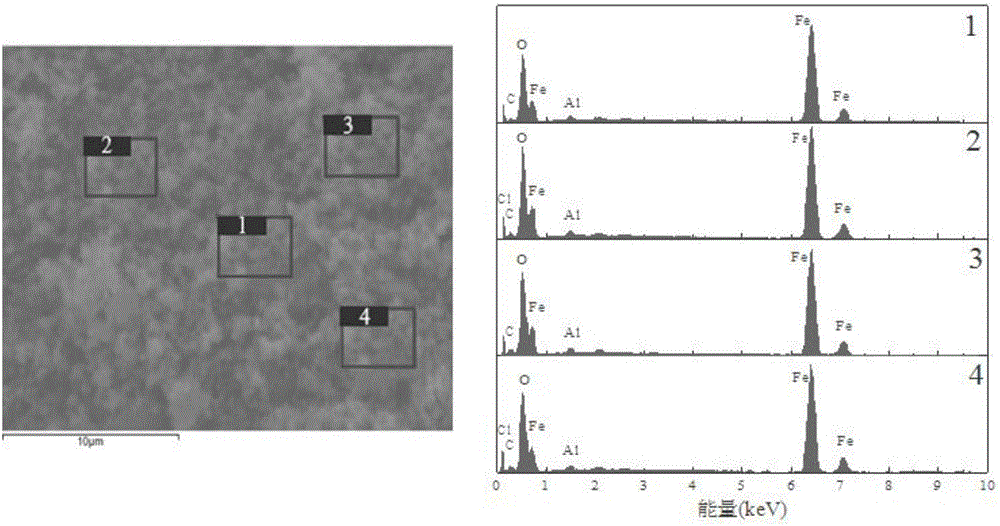

[0043] Add 3.601g NaOAc to the solution containing 3.703g FeCl 3 ·6H 2 O in ethylene glycol (9mL) solution, stirred evenly to obtain a mixed solution; then 0.5ml of aluminum isopropoxide solution (saturated isopropoxide solution of aluminum isopropoxide, wherein the content of aluminum isopropoxide is 0.033 g) adding to the mixed solution, stirring evenly to obtain a reaction solution; the reaction solution was heated to 198°C for 36 hours of constant temperature reaction, annealed and cooled, and the obtained solid particles were collected by magnetic separation, and finally washed and dried to obtain the aluminum-modified Fe 3 o 4 Magnetic material (denoted as Fe 3 o 4 - AIP-2, the average aluminum content measured by EDX is 0.42 wt%).

Embodiment 3

[0045] A kind of aluminum modified Fe 3 o 4 Magnetic material, its preparation method comprises the following steps:

[0046] Add 1.800g NaOAc to the solution containing 1.852g FeCl 3 ·6H 2 O in ethylene glycol (4.5mL) solution, stirred evenly to obtain a mixed solution; then 4ml of aluminum isopropoxide solution (saturated isopropoxide solution of aluminum isopropoxide, wherein the content of aluminum isopropoxide is 0.266 g) adding to the mixed solution, stirring evenly, to obtain a reaction solution; the reaction solution was heated to 198°C for 24 hours at a constant temperature, annealed and cooled, and the obtained solid particles were collected by magnetic separation, and finally washed and dried to obtain the aluminum-modified Fe 3 o 4 Magnetic material (denoted as Fe 3 o 4 - AIP-3, the average content of aluminum measured by EDX is 3.15 wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com